Backheating and heating technology by using residual heat of exhaust steam in steam power cycle

A technology of steam power and waste heat, which is applied in steam central heating systems, household heating, heating systems, etc., and can solve problems such as low engineering cost, low temperature and pressure, and recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

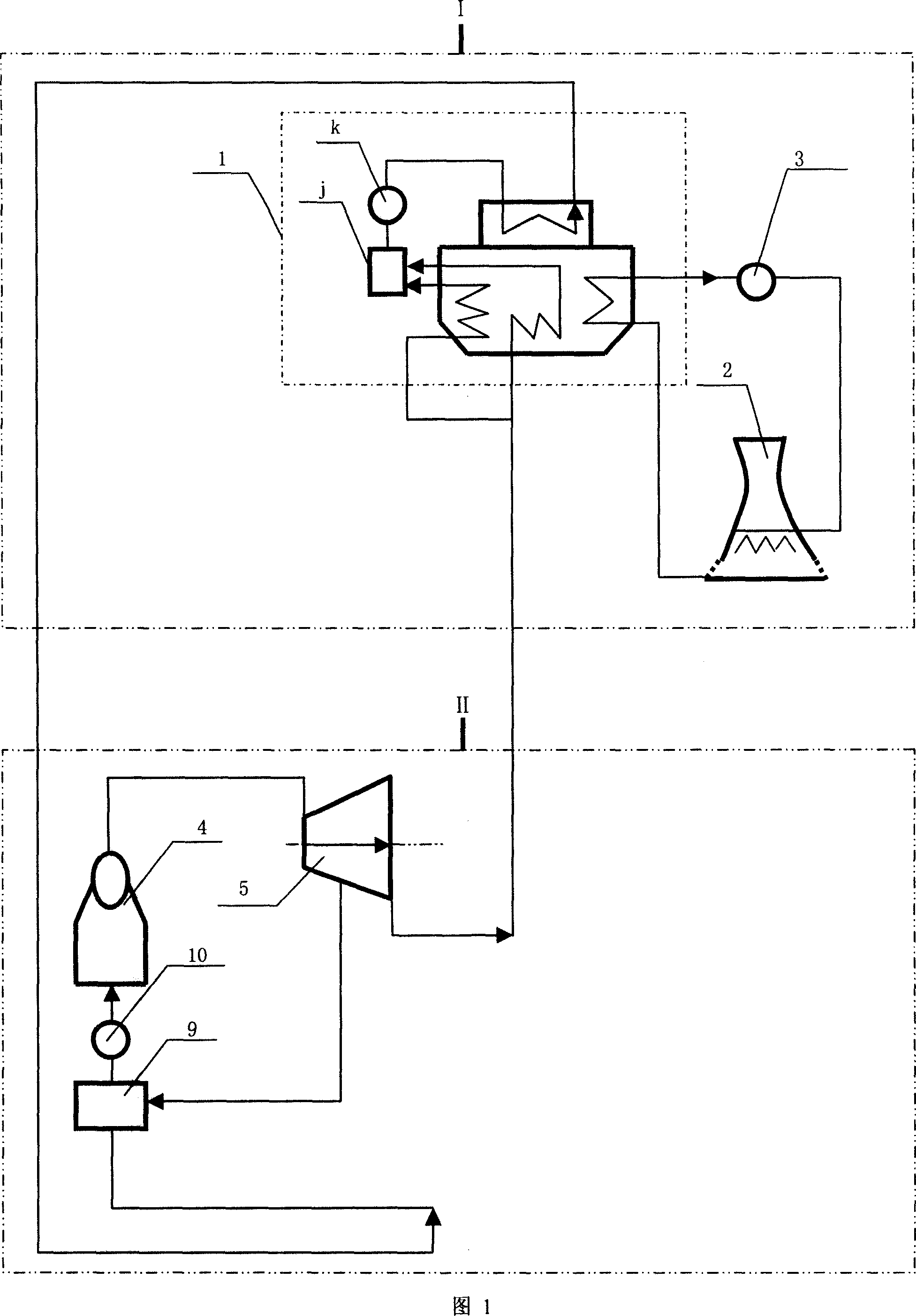

[0054] Fig. 1 shows the process flow of the exhaust steam recovery scheme using the second-type absorption heat pump. At this time, the exhaust steam at the outlet of the steam turbine 5 in the steam power cycle is connected to the second-type absorption heat pump 1, and the heat pump cooling system 2 is connected to the heat pump 1. Condenser, the exhaust steam participates in the corresponding process of the heat pump, then goes through the step-up pump k to boost the pressure, enters the heat pump absorber to absorb heat and heat up, and then returns to the steam power cycle system, enters the regenerator 9, and then passes through the feed water pump after pumping steam to heat up 10 into the boiler or steam generator 4, or directly through the feed pump 10 into the boiler or steam generator 4.

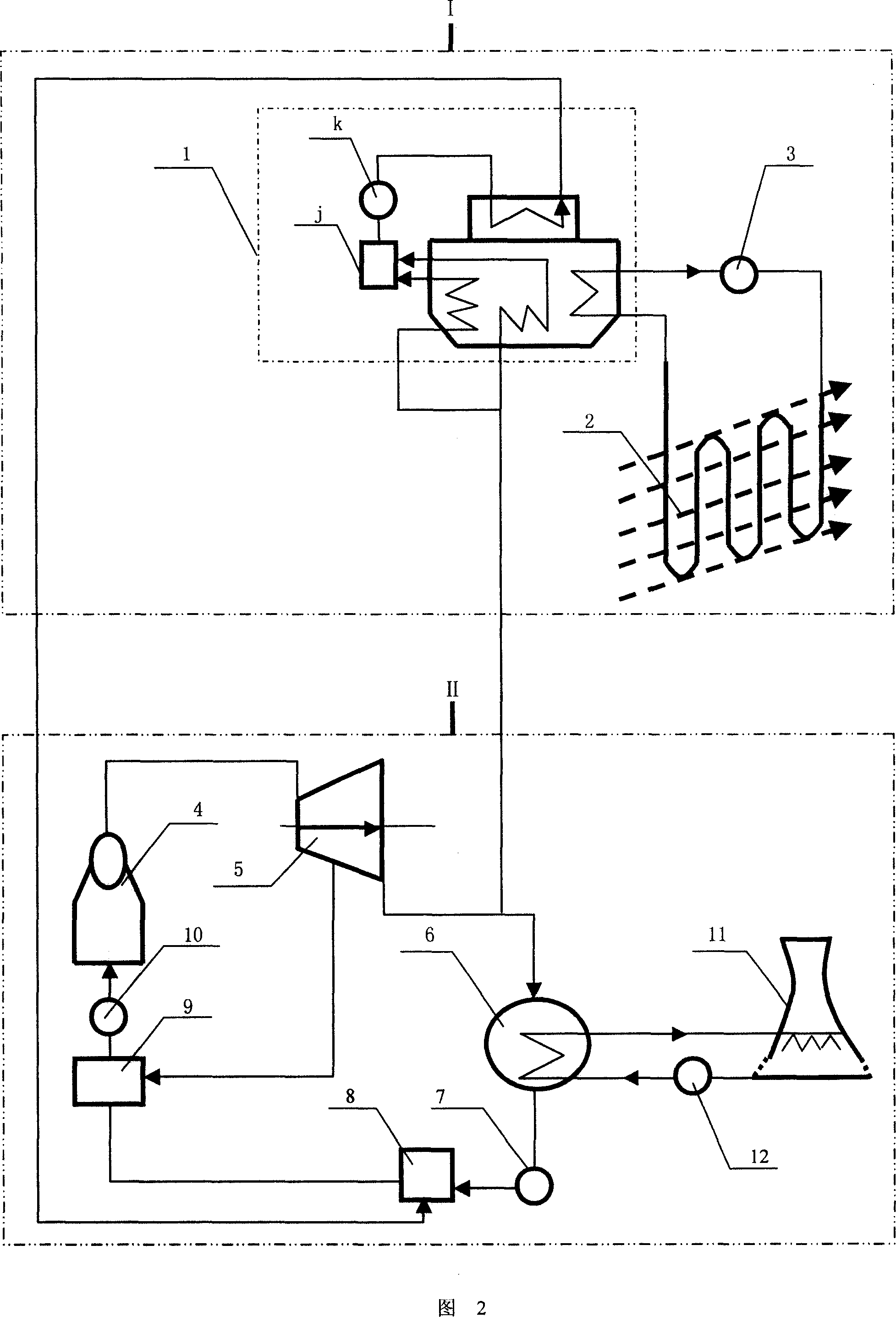

[0055] The system shown in Fig. 2 is basically the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com