Tail flue gas waste heat utilizing system of utility boiler based on hot blast recycling

A technology for flue gas waste heat and power plant boilers, applied in preheating, liquid degassing, feed water heaters, etc., can solve the problems of reduced system operation reliability, increased operating costs, reduced economy, etc., to reduce the heat transfer surface The effect of investment, improvement of power generation efficiency, and reduction of steam extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

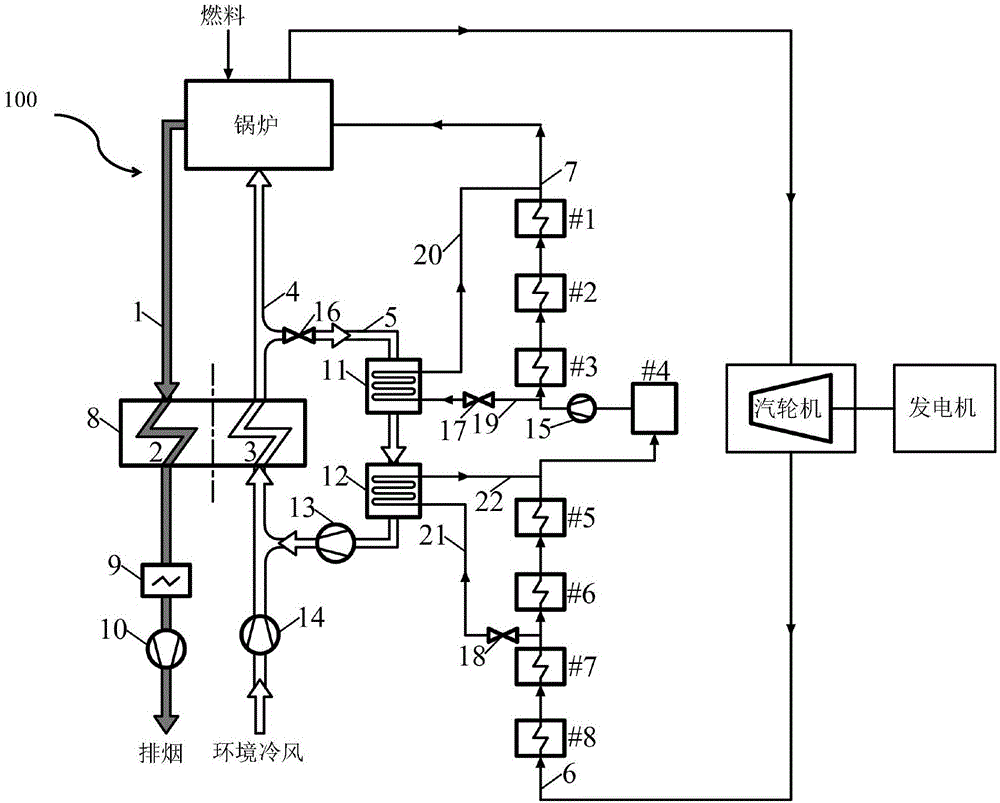

[0035] figure 1 It is a schematic diagram of the system composition of the present invention.

[0036] like figure 1 As shown, power generation system 100 has a boiler plant including a boiler that produces steam and a turbogenerator plant including a steam turbine and a generator.

[0037] The boiler unit generates high-temperature and high-pressure steam and enters the steam turbine to do work to drive the output shaft of the steam turbine to rotate, and the output shaft drives the connected generator to rotate at high speed to generate electricity.

[0038] like figure 1 As shown, the boiler unit is used to burn fuel in the boiler and is connected with a steam turbine generator unit containing a steam turbine driven by steam, including a boiler feed water recovery heating device and a boiler tail flue gas waste heat utilization device.

[0039] Boiler feed water recovery heating device, with a low-pressure heating unit composed of four steam extraction heaters (#5~#8 ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com