Device and method for compressing air and flue gas in oxygen-rich combustion system and recycling residual heat

A technology of oxygen-enriched combustion and waste heat recovery, applied in chemical instruments and methods, combined devices, separation methods, etc., can solve problems such as national economic loss and efficiency decline, and achieve the goal of reducing steam extraction, improving service life, and improving system efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

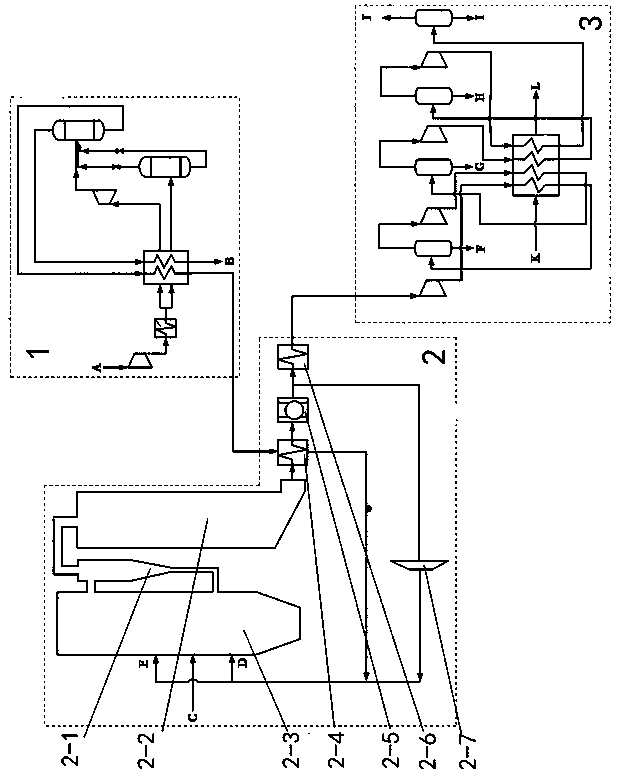

[0029] Embodiment 1: as figure 1 The shown device for air and flue gas compression and waste heat recovery in an oxyfuel combustion system includes an air separation unit 1, a circulating fluidized bed boiler unit 2, and a carbon dioxide compression and purification unit 3; the circulating fluidized bed boiler unit 2 includes : Fluidized bed furnace 2-3, cyclone separator 2-1, tail convection flue 2-2, oxygen preheater 2-4, flue gas dust collector 2-5, flue gas water supply heat exchanger 2-6 and Circulating fan 2-7; the fluidized bed furnace 2-2 is provided with a coal feed port C, a primary air inlet D, and a secondary air inlet E, and the fluidized bed furnace 2-3 passes through the cyclone separator 2-1 Connect the tail convection flue 2-2, and the end of the tail convection flue 2-2 is sequentially connected to the heat exchange tube of the oxygen preheater 2-4, the flue gas dust collector 2-5 and the flue gas water supply heat exchanger 2 through pipelines -6, the end o...

Embodiment 2

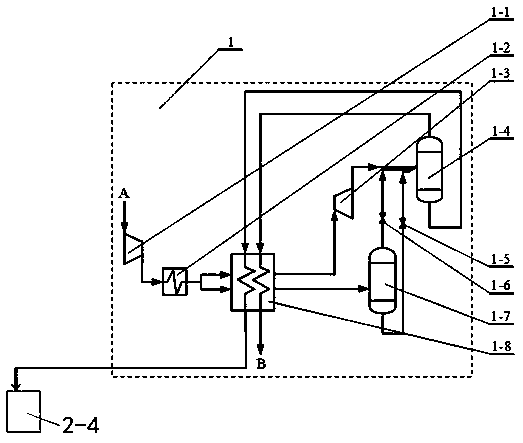

[0030] Embodiment 2: as figure 2 As shown, the air separation assembly 1 includes an air compressor 1-1, an air-to-water heat exchanger 1-2, an air cooler 1-8, an air turbine 1-3, a first throttle valve 1-6, a second section Stream valve 1-5, upper rectification tower 1-4 and lower rectification tower 1-7; Described air compressor 1-1 connects the heating pipe of air cooler 1-8 through air-to-water heat exchanger 1-2 The heating pipeline of the air cooler 1-8 is respectively connected to the air turbine 1-3 and the lower rectification tower 1-7 through two air pipes, and the upper and lower ends of the lower rectification tower 1-7 are respectively provided with first Throttle valve 1-6 and second throttle valve 1-5, air turbine 1-3, first throttle valve 1-6 and second throttle valve 1-5 are all connected to upper rectifying column 1-4 The upper and lower ends of the upper rectifying tower 1-4 are connected to the heat exchange pipeline of the air cooler 1-8, and the heat exch...

Embodiment 3

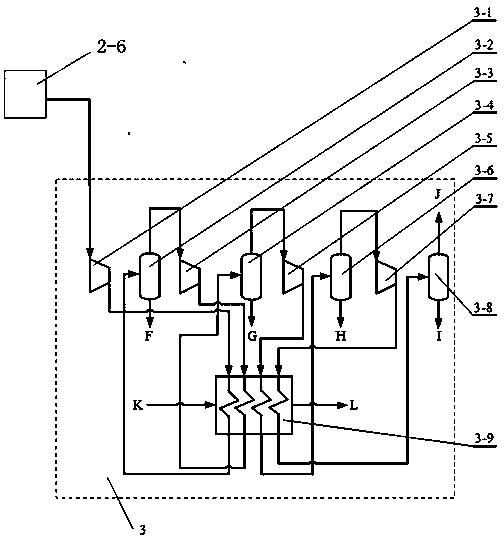

[0031] Embodiment 3: as image 3 As shown, the carbon dioxide compression and purification assembly 3 is composed of a carbon dioxide feed water heat exchanger 3-9 and a multi-stage compression dehydration unit, and each stage compression dehydration unit is composed of a single carbon dioxide compressor 3-1, 3-3, 3-5, 3-7 and a single carbon dioxide dehydration device 3-2, 3-4, 3-6, 3-8; the flue gas feed water heat exchanger 2-6 is connected to the carbon dioxide compressor of the first stage compression dehydration unit On the air inlet of 3-1, the carbon dioxide compressor 3-1 is connected to the carbon dioxide dehydration device 3-2 through the carbon dioxide water supply heat exchanger 3-9, and the bottom of the carbon dioxide dehydration device 3-2, 3-4, 3-6, 3-8 Condensed water outlets F, G, H, I are provided, and the top of the carbon dioxide dehydration device 3-2 is connected to the inlet port 3-3 of the carbon dioxide compressor of the next-stage compression dehydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com