Regenerative system of low-pressure drain water cooler

A technology of hydrophobic cooling and heat recovery system, applied in the direction of feed water heaters, preheating, chemical instruments and methods, etc., can solve the problems of reducing unit economy, long-time start-up, heat loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

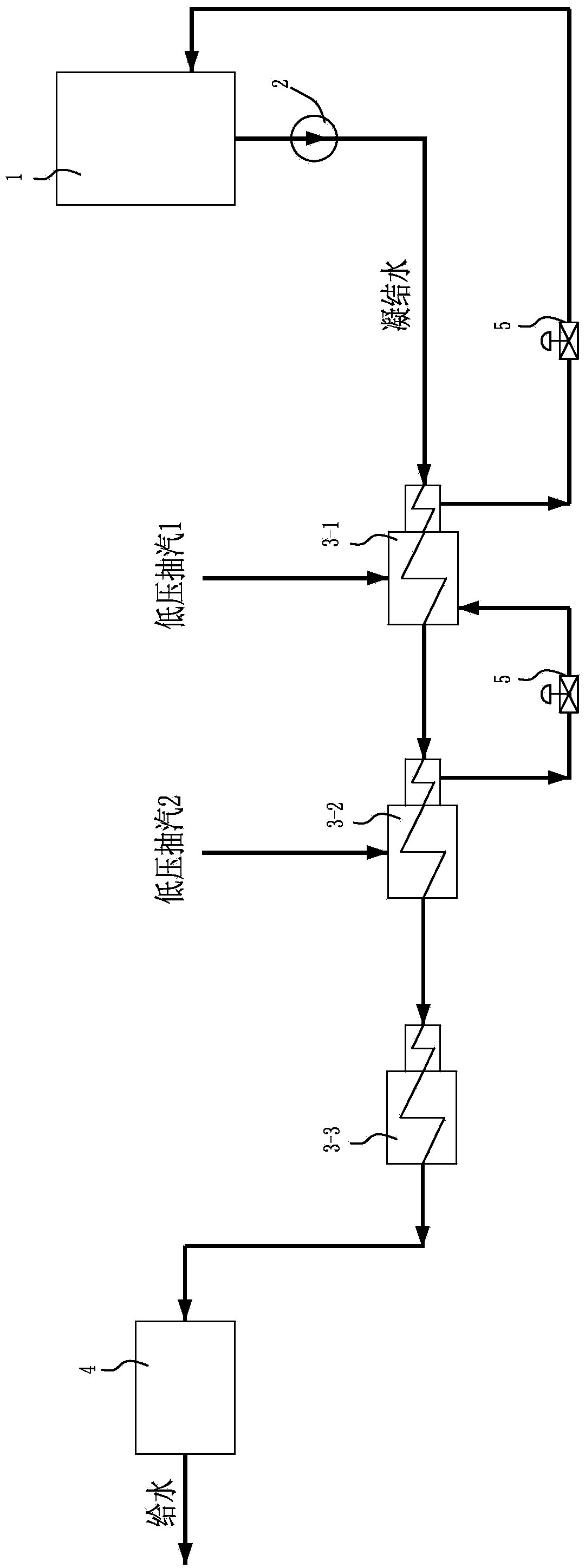

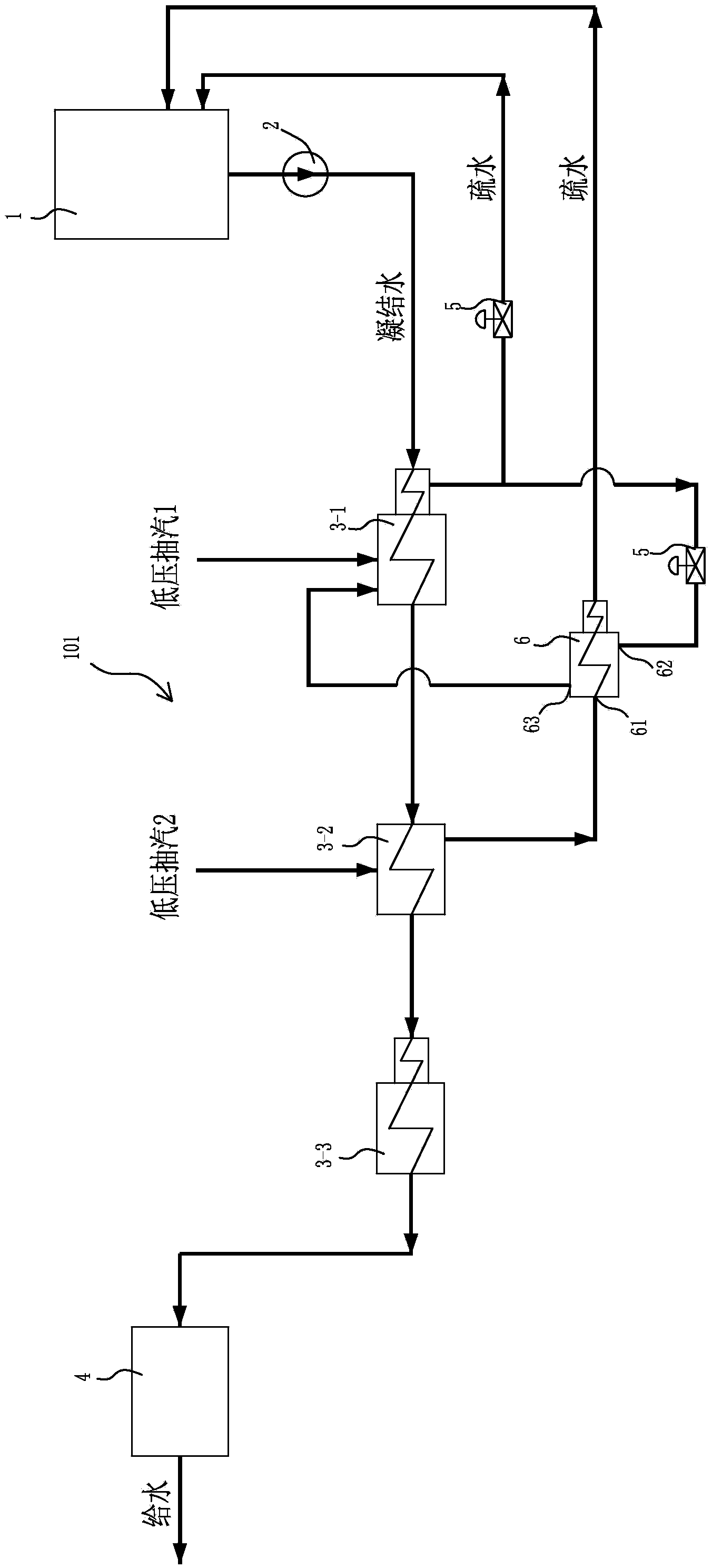

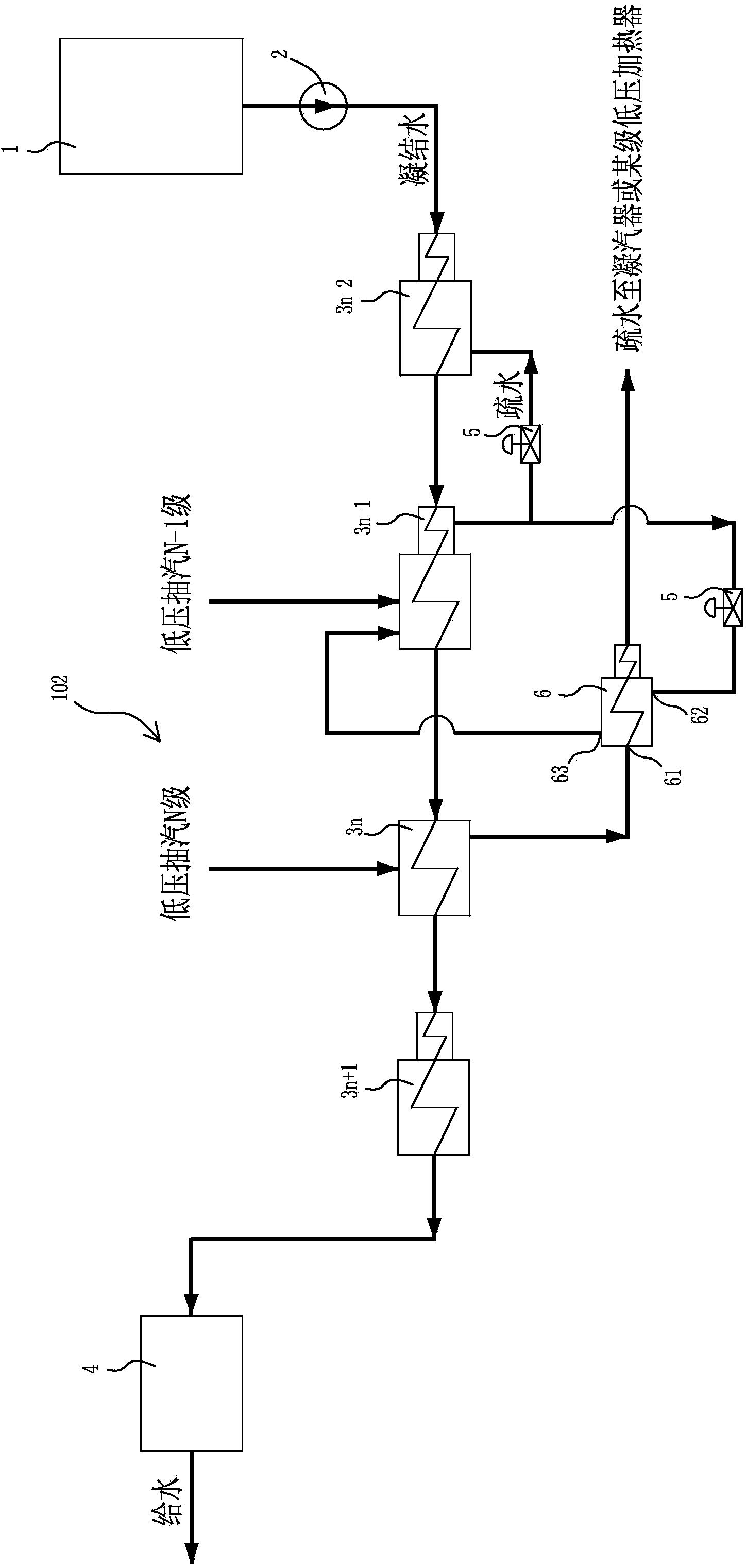

[0021] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings, so as to better understand the purpose, features and advantages of the present invention. It should be understood that the embodiments shown in the drawings are not intended to limit the scope of the present invention, but only to illustrate the essence of the technical solutions of the present invention.

[0022] In this article, "upper-stage low-pressure heater" and "lower-stage low-pressure heater" refer to the flow direction of condensed water in the regenerative system, which is closer to the condensate than a certain stage of low-pressure heater. The first-stage low-pressure heater at the position of the condenser is called the "lower-stage low-pressure heater", and the first-stage low-pressure heater farther away from the condenser is called the "upper-stage low-pressure heater".

[0023] Terminology Explanation

[0024] Drainage cooler: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com