Condensed water circulating cooling energy-conserving and emission-cutting technology

A water cycle cooling, energy-saving and emission-reducing technology, applied in energy-saving heating/cooling, steam engine installation, climate sustainability, etc., can solve the problems of loss of precious water resources, waste of low-temperature heat energy, environmental heat pollution, etc., and achieve environmental protection and social benefits Significantly, the effect of reducing coal consumption for power generation and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Take the drawings as an example to further describe the present invention

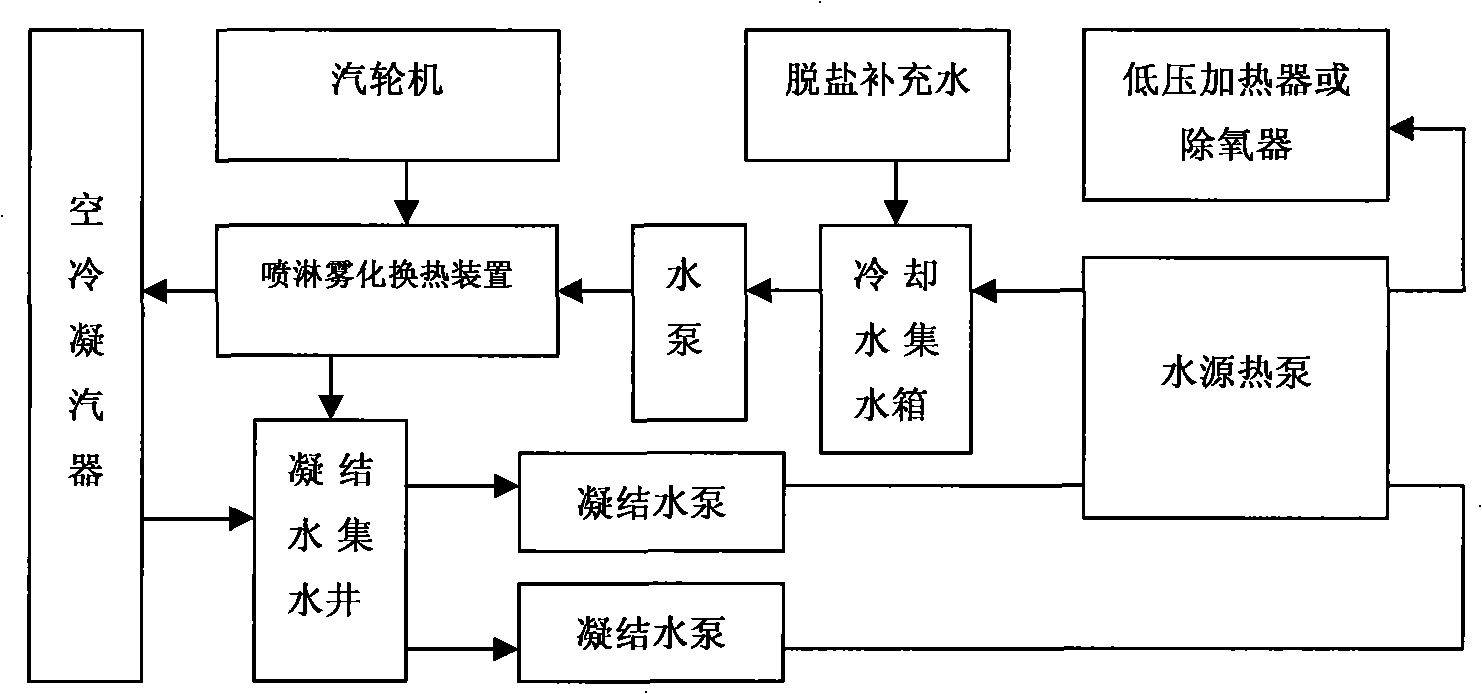

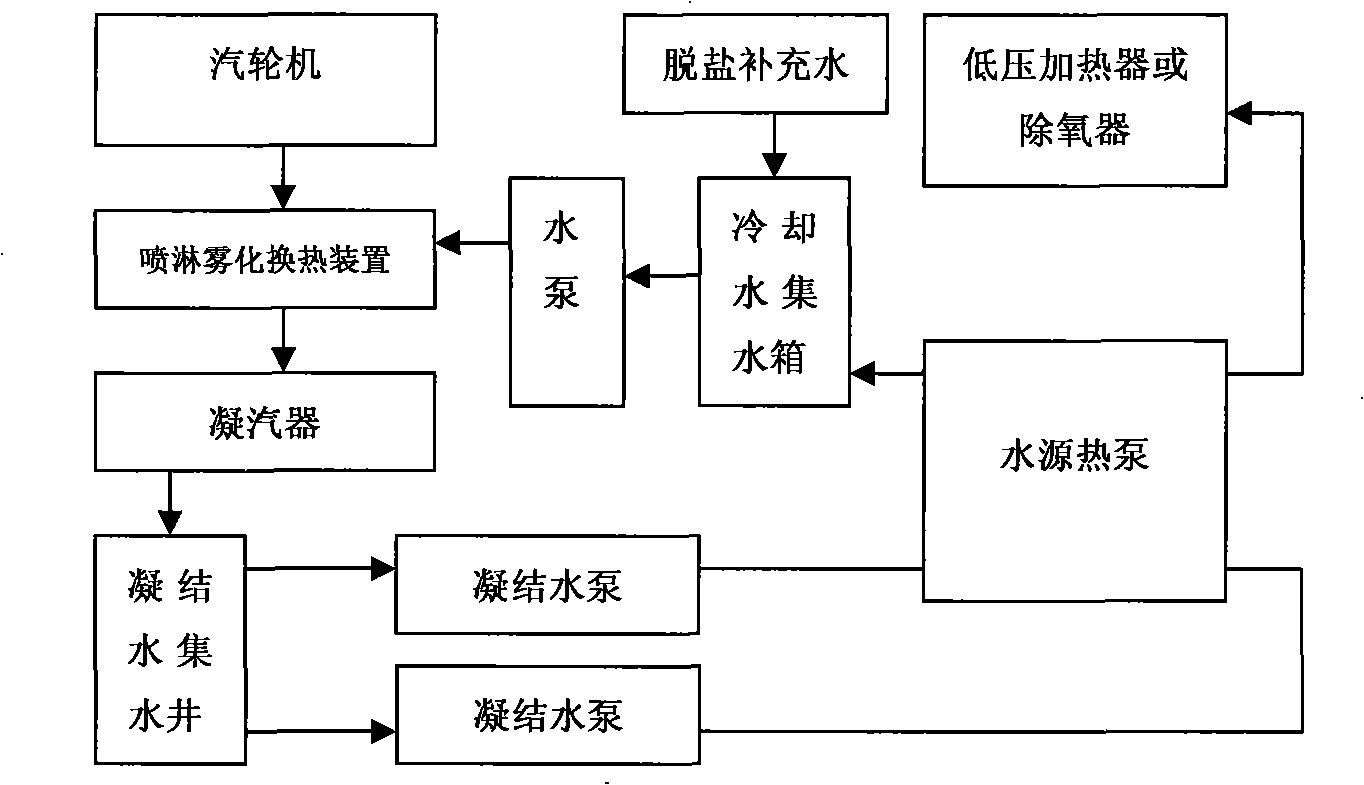

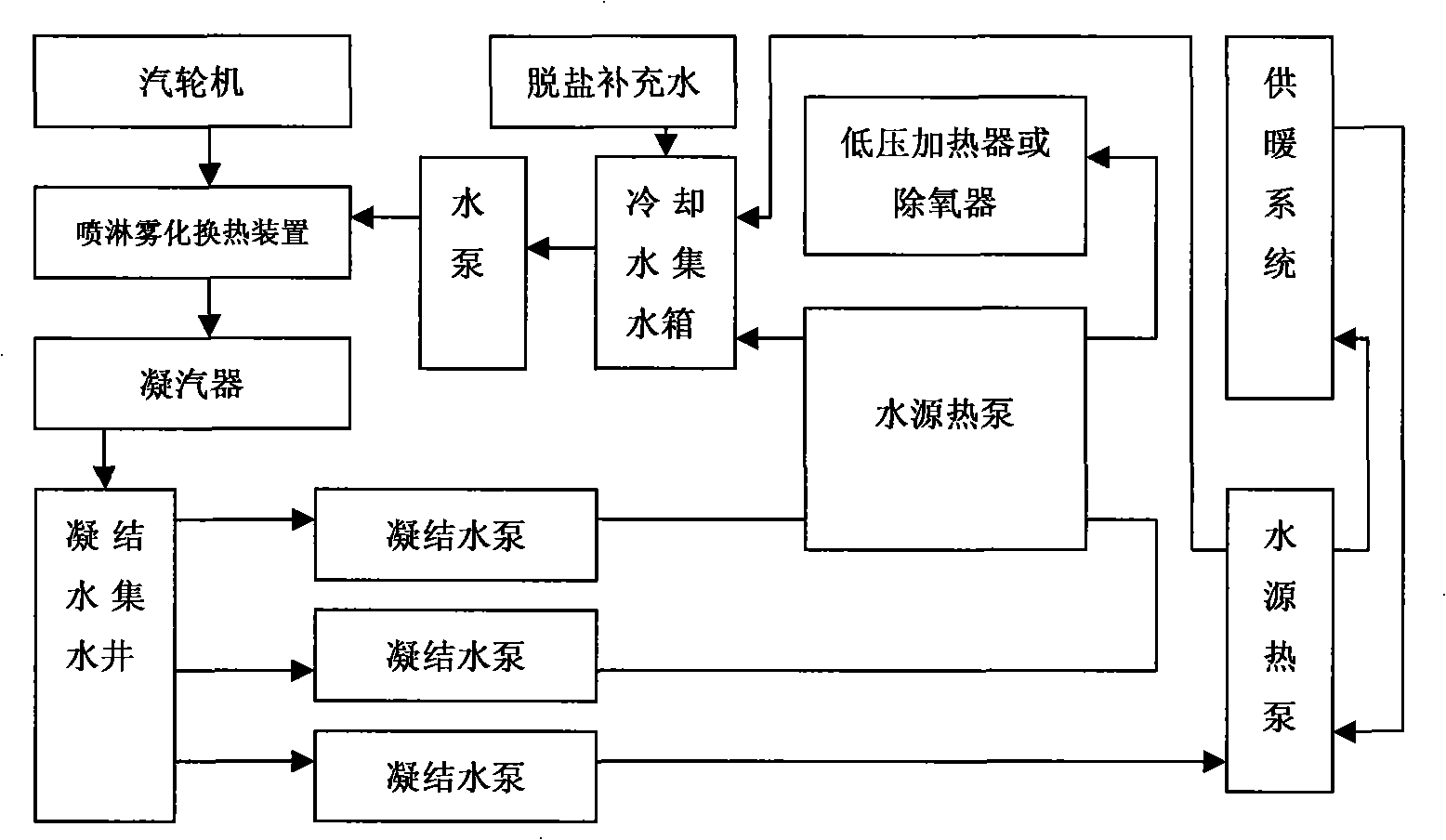

[0021] figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 It is a process flow diagram of an embodiment of the present invention

[0022] Condensate circulating cooling energy saving and emission reduction technology (such as figure 1 , figure 2 , image 3 , Figure 4 (Shown), at the high temperature end of the steam turbine exhaust pipe, the condensed water spray atomized steam water is directly mixed and condensed by heat exchange. The condensate after heat exchange and condensation flows into the condensate collection well, and is sent to the water source heat pump by the condensate pump through the water source After the heat pump is refrigerated, it is sent back to the high temperature end of the exhaust pipe to spray and atomize to form a cooling cycle. At the same time, the water source heat pump converts the waste heat to boiler feed water of the same water quality or heating and oth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com