System for increasing garbage incinerator steam temperature through percolate marsh gas

A waste incineration and leachate technology, which is applied in steam application, steam generation, steam engine installations, etc., can solve problems such as low-temperature corrosion of air preheaters, reduction of steam used for power generation, and complex flue gas components, so as to save and increase costs, The effect of saving the steam extraction volume of the steam turbine and avoiding high temperature corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

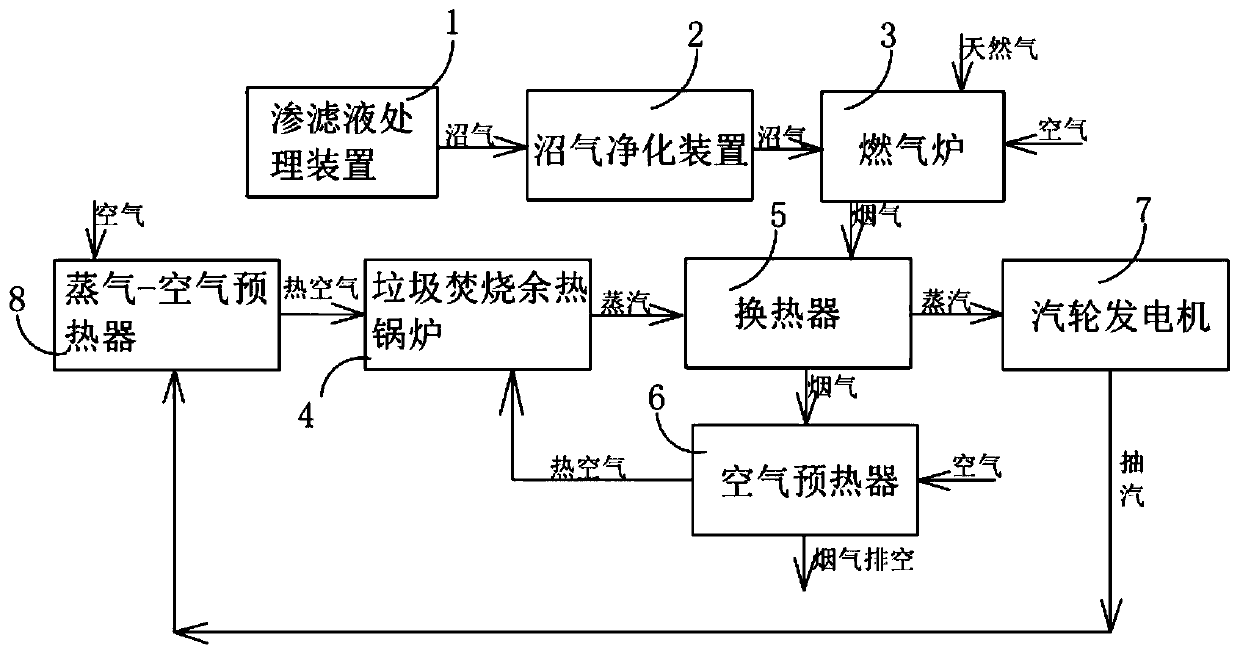

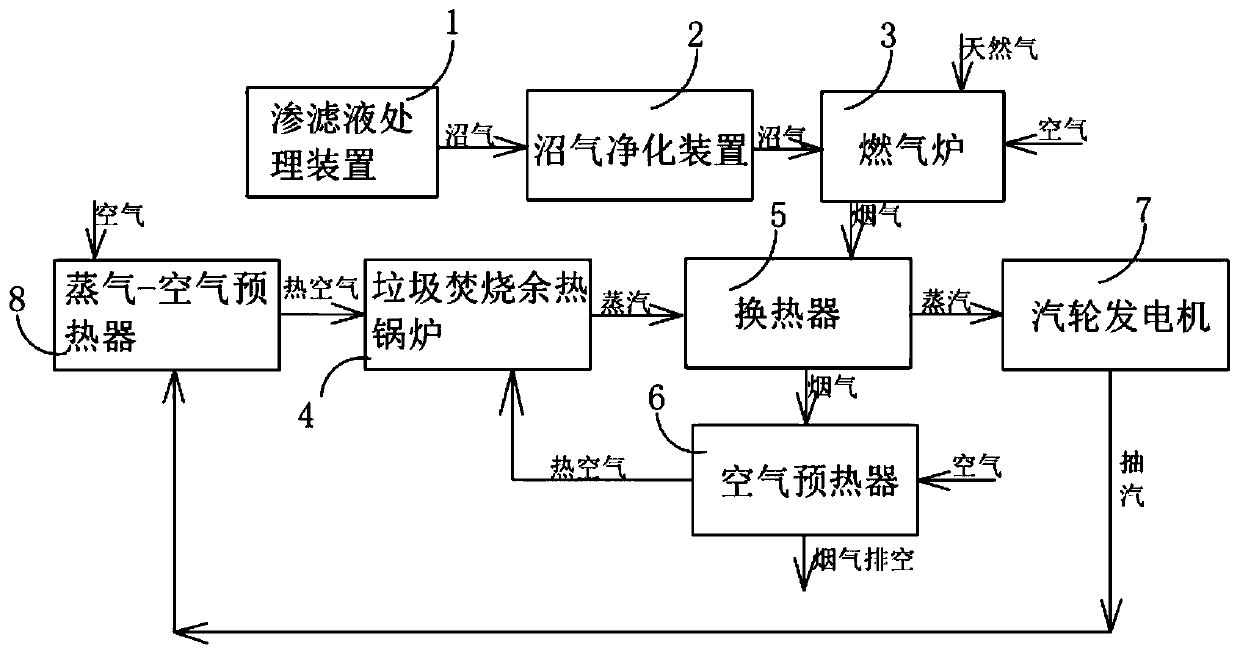

[0020] figure 1 It is a system layout diagram of an embodiment proposed by the present invention. The figure shows, in this example, a system for increasing the steam temperature of a waste incinerator by using leachate biogas, including leachate treatment device 1, biogas purification device 2, gas furnace 3, waste incineration waste heat boiler 4, heat exchanger 5, Air preheater 6, turbo generator 7 and steam-air preheater 8. The biogas produced by the leachate treatment device 1 passes through the biogas purification device 2 and then enters the gas furnace 3 for combustion. The high-temperature flue gas generated enters the heat exchanger 5 to heat up the steam in the heat exchanger 5, and then the high-temperature flue gas enters the air for preheating The air heater 6 heats the air, and the generated hot air is transported to the waste incineration waste heat boiler 4, and the high-temperature flue gas enters the heat exchanger 5 and is discharged after heat exchange; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com