Exhaust-gas aftertreatment device

A technology of exhaust gas post-treatment and internal combustion engine, which is applied in the direction of exhaust gas treatment, exhaust device, internal combustion piston engine, etc. It can solve the problems of not participating in the combustion process of the engine, and the capture material is easy to age, and achieve the effect of improved mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

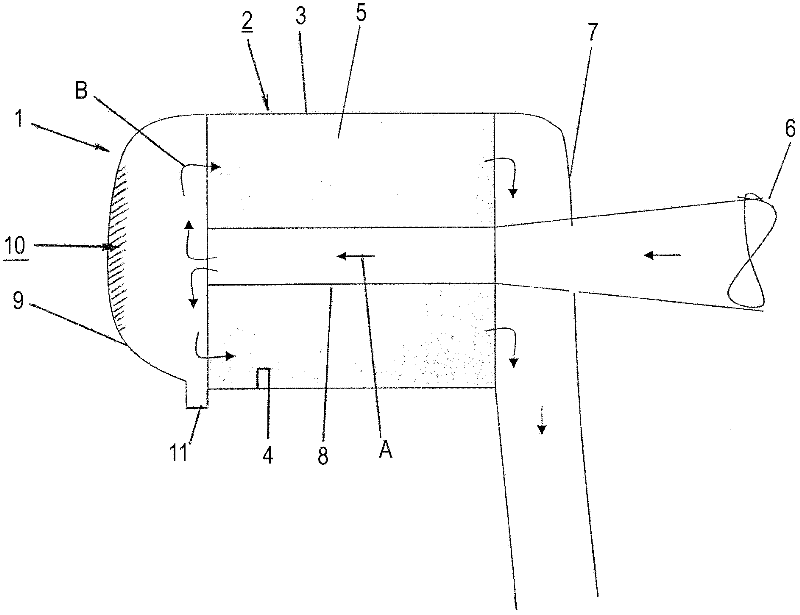

[0022] An exhaust gas aftertreatment device 1 according to the invention is provided for improving the catalytic conversion of exhaust emissions from an internal combustion engine (not shown). The internal combustion engine can be of any suitable type, such as is used in vehicles and other engine driven machinery.

[0023] as passed figure 1 It can be seen that the exhaust gas aftertreatment device 1 according to the invention is provided with a catalytic converter 2 which thus forms part of the device.

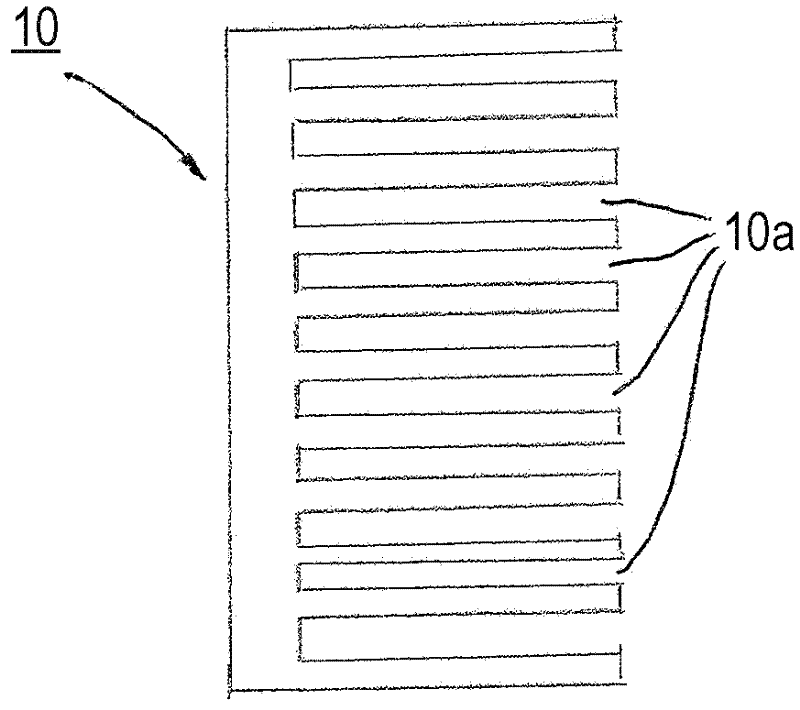

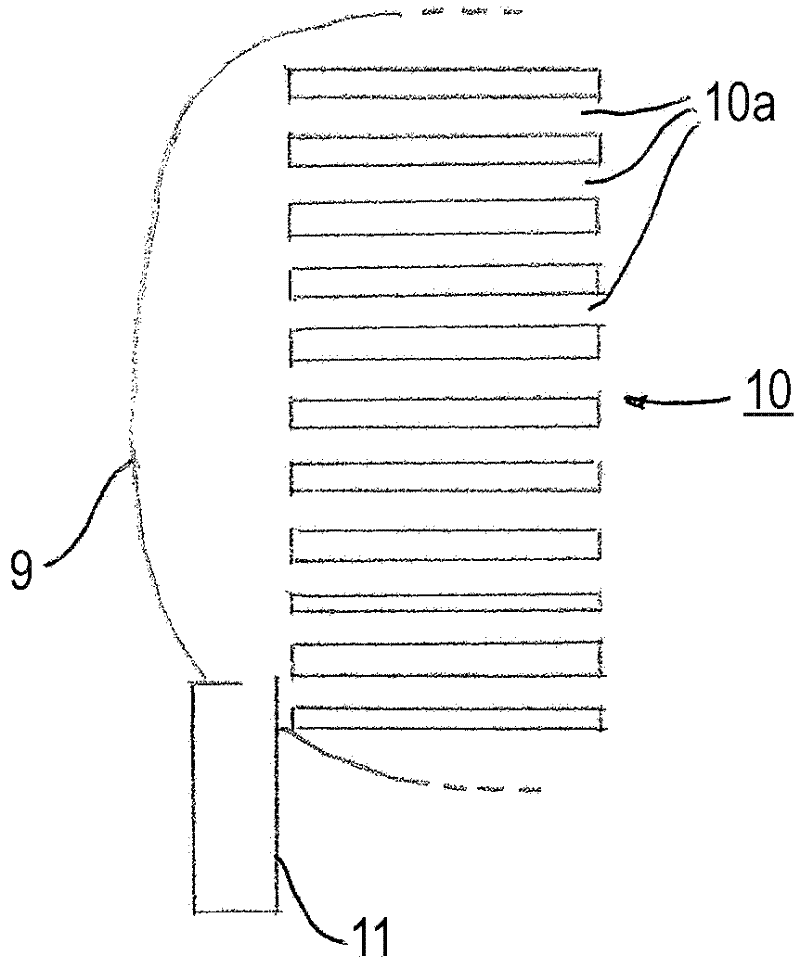

[0024] The catalytic converter 2 forming part of the device 1 may be of any suitable type and thus in figure 1 are shown schematically only. figure 1 The catalytic converter 2 shown in includes a tubular member 3 . This tubular member, which may be circular, square, rectangular or any other suitable shape in cross-section, defines a space 4 in which a catalytic converter substrate 5 of a suitable type is positioned. The space 4 in the tubular member 3 with the catalytic c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com