Electric dry oven capable of saving energy and reducing emission

A technology of energy saving and emission reduction and electric oven, which is applied in the direction of drying, drying machines, lighting and heating equipment, etc., and can solve problems that do not meet energy saving and emission reduction, environmental pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

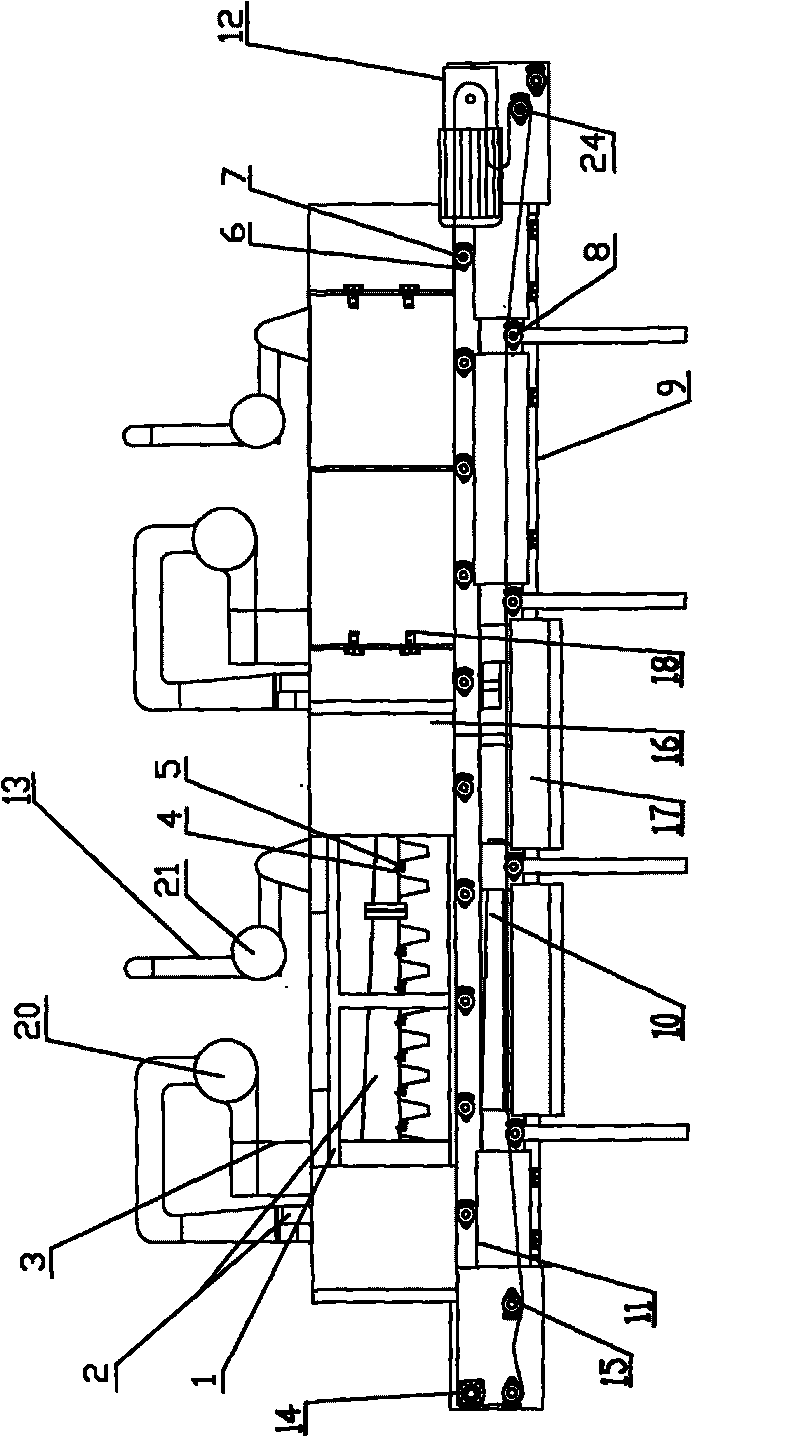

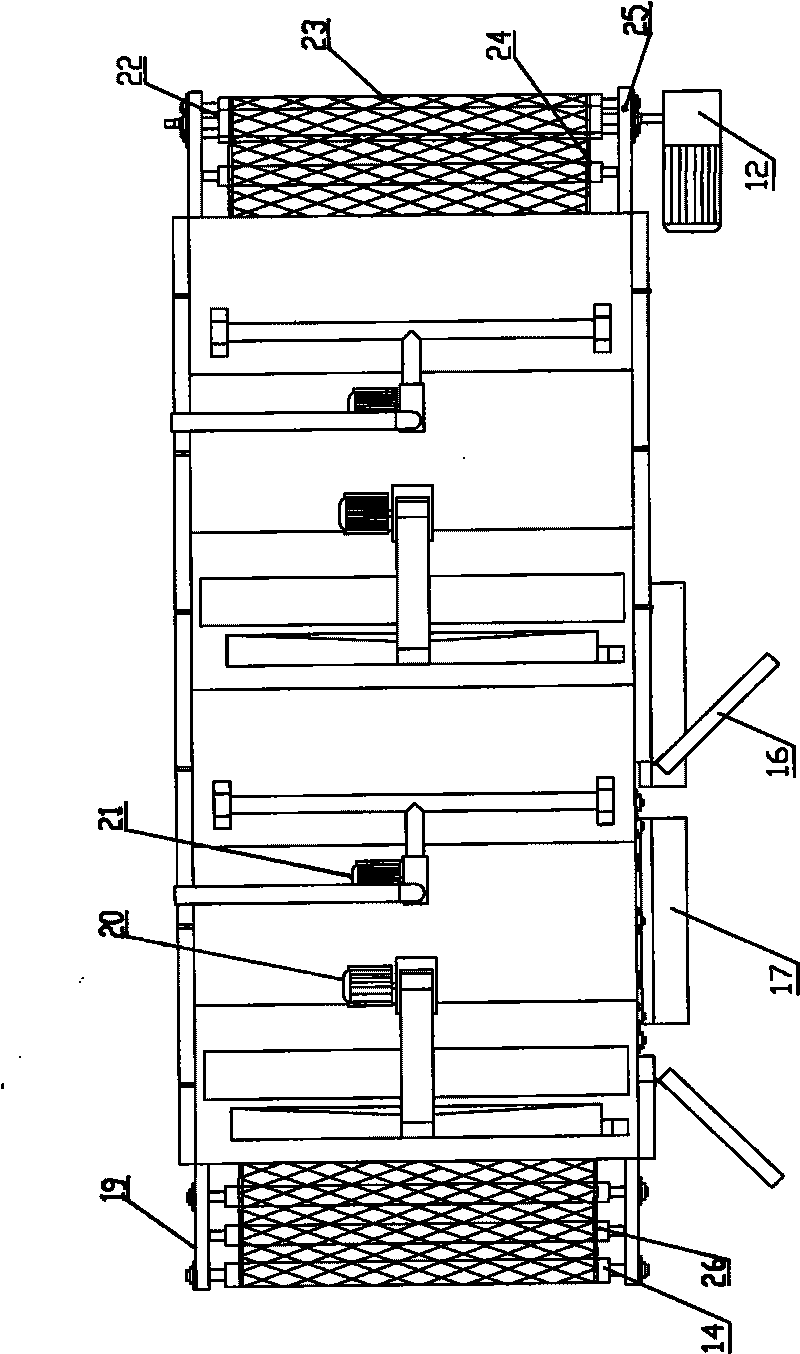

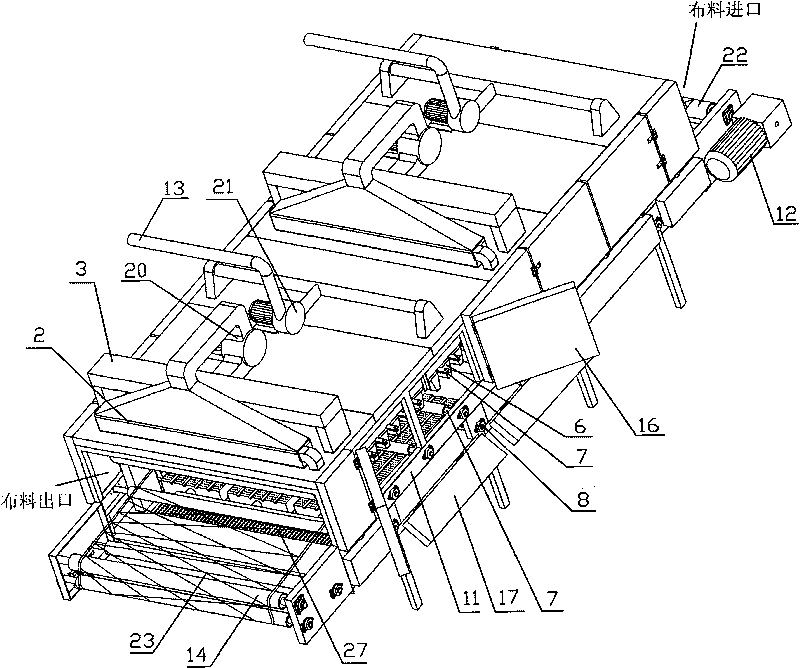

[0026] Refer to attached Figure 1~3 , The energy-saving and emission-reducing electric oven includes box frame 1 (skeleton), circulating fan 20, circulating upper air duct 2, circulating lower air duct 10, circulating air outlet 3, heating pipe clamp 4, medium-wave infrared radiation heating pipe 5, and upper guide belt Roller 7, lower belt guide roller 8, bearing 6, needle plate chain guide rail or mesh belt 23, reduction motor 12, idler beam 11, air outlet filter plate 27.

[0027] Insulation panels 9 are installed around the frame 1, oven insulation door panels 16 are installed on both sides of the frame 1 through hinges 18, oven insulation lower door panels 17 are installed at the bottom of the frame 1, and several groups of heating pipes are installed in the frame. Clip 4, several mid-wave infrared radiation heating tubes 5 are installed on several sets of heating tube clips 4 respectively, and the mid-wave infrared radiation heating tubes 5 are commercially available mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com