Energy-saving fan of spinning frame

A spinning frame and fan technology, applied to spinning machines, machines/engines, mechanical equipment, etc., can solve the problems of increasing the energy consumption burden of enterprises, conflicting spirits of energy-saving and energy-saving, and achieve the effects of pressure loss avoidance, energy saving and dust removal , the effect of reducing power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

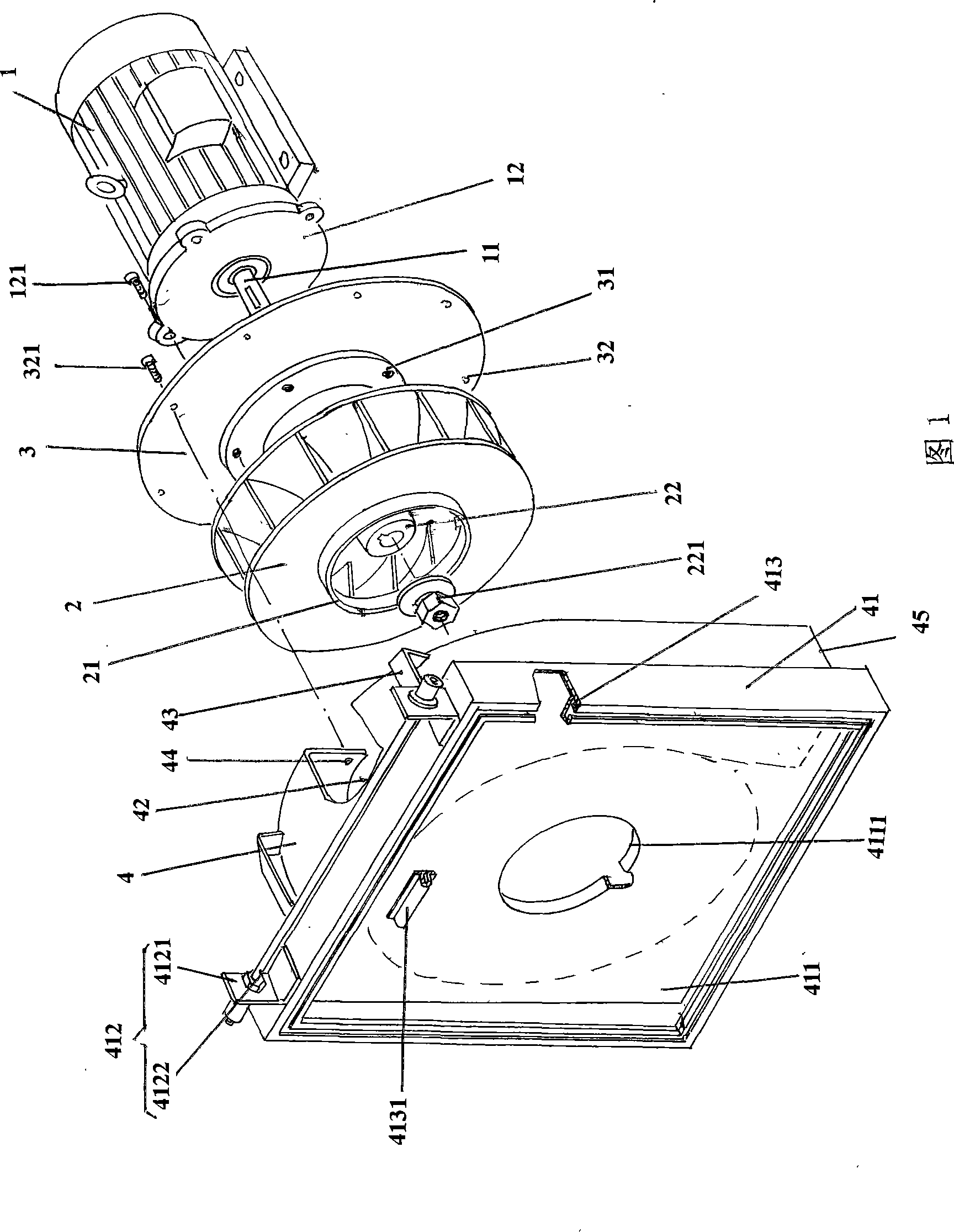

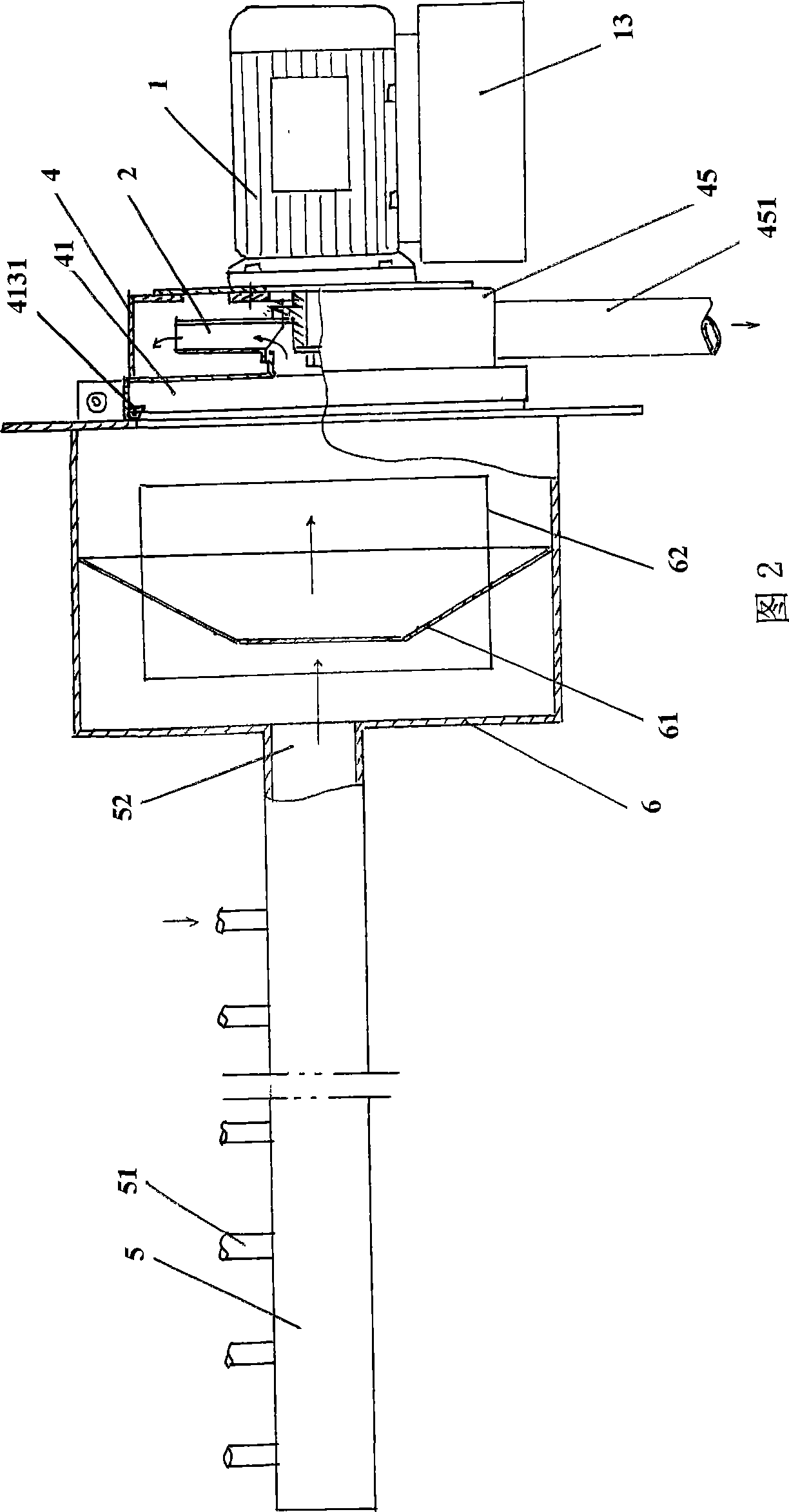

[0021] Please see Fig. 1, the provided motor 1 is a three-phase asynchronous motor, the front cover 12 of the motor 1 is fixed with the first screw 121 and the first screw fixing hole 31 on the rear cover 3, and the first screw 31 on the rear cover 3 is fixed. The second screw fixing hole 32 is used for fixing the second screw 321 to the preset third screw fixing hole 44 on the volute 4 . Centrifugal fan 2 is fixed with the power output shaft 11 of motor 1 by the fan shaft seat 22 in its center, and is also limited by fixing nut 221, and fixing nut 221 is screwed on the shaft head of power output shaft 11, because in The shaft head of the power take-off shaft 11 is processed with external threads. After the rear cover 3 and the volute 4 are fixed, the whole centrifugal fan 2 is integrally located in the cavity 42 of the volute 4 .

[0022] The given volute 4 has a rectangular docking disc 41 in shape, more specifically a square in shape, and the concept of the docking disc 41...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com