Gelatin hydrogel and preparation method and application thereof

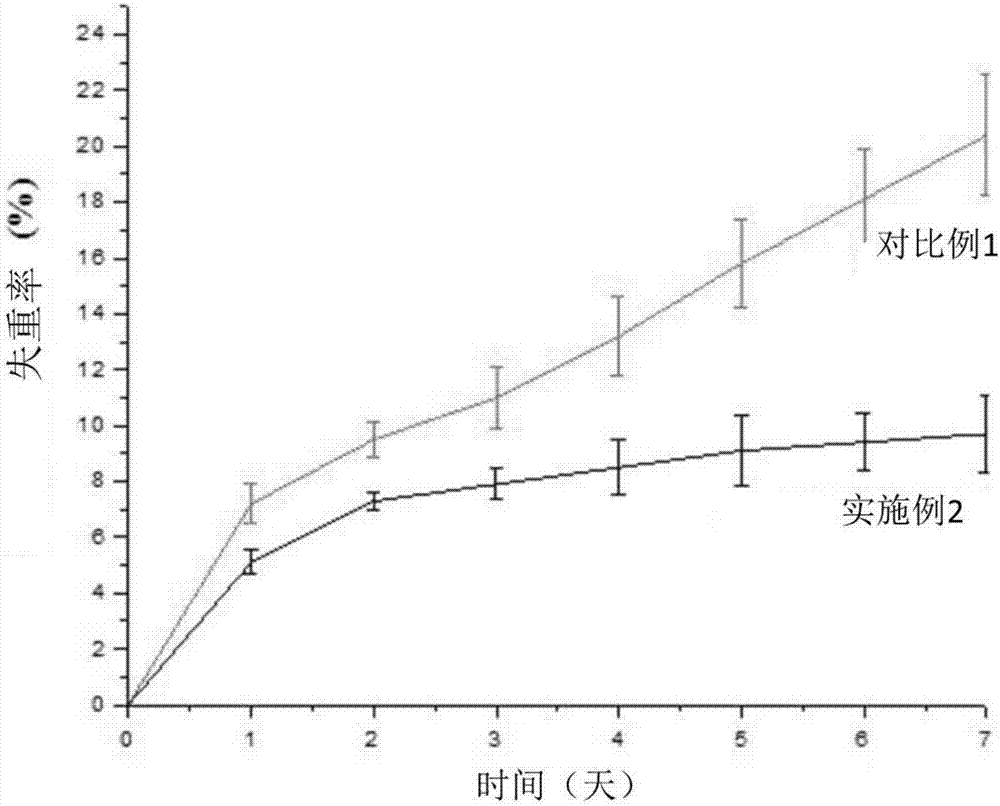

A hydrogel and gelatin technology, applied in the field of gelatin hydrogel and its preparation, can solve the problems of poor mechanical properties of pure gelatin hydrogel, cannot maintain a gel state, and limit the scope of application, and achieves overcoming poor mechanical strength, The effect of increasing the cross-linking point and realizing the degree of cross-linking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A kind of preparation of gelatin hydrogel, comprises the steps:

[0047] (1) Weigh 10 g of gelatin and add it to 100 mL of deionized water, swell at room temperature for 1 h, and stir in a constant temperature water bath at 60°C until completely dissolved. Add 16mL of methacrylic anhydride dropwise to the gelatin solution at a rate of 1mL / min, shake and react in a constant temperature shaker at 50°C for 4h, then add 400mL of deionized water at 50°C to dilute the reaction solution, and fill the diluted solution with Put it into a 8-14kDa dialysis bag, dialyze in deionized water at 50°C for 1 week, replace the deionized water every 4 hours, centrifuge the dialysate at 3000rpm for 10min after the end, take the supernatant, and put it in a -80°C refrigerator overnight, and freeze-dried for 3 days to obtain methacrylamide-based gelatin with a modification degree of 88%.

[0048] (2) Prepare 50 mL of an aqueous solution of Irgacure 2959 with a mass concentration of 0.25 wt%,...

Embodiment 2

[0050] A kind of preparation of gelatin hydrogel, comprises the steps:

[0051] (1) Weigh 10 g of gelatin and add it to 100 mL of deionized water, swell at room temperature for 1 h, and stir in a constant temperature water bath at 60°C until completely dissolved. Add 16mL of methacrylic anhydride dropwise to the gelatin solution at a rate of 1mL / min, shake and react in a constant temperature shaker at 50°C for 4h, then add 400mL of deionized water at 50°C to dilute the reaction solution, and fill the diluted solution with Put it into a 8-14kDa dialysis bag, dialyze in deionized water at 50°C for 1 week, replace the deionized water every 4 hours, centrifuge the dialysate at 3000rpm for 10min after the end, take the supernatant, and put it in a -80°C refrigerator overnight, and freeze-dried for 3 days to obtain methacrylamide-based gelatin with a modification degree of 88%.

[0052] (2) Prepare 50 mL of an aqueous solution of Irgacure 2959 with a mass concentration of 0.5 wt%, ...

Embodiment 3

[0062] A kind of preparation of gelatin hydrogel, comprises the steps:

[0063] (1) Weigh 1000g of gelatin and add it to 10L of deionized water, swell at room temperature for 1 hour, and stir in a constant temperature water bath at 60°C until completely dissolved. Add 800mL of methacrylic anhydride dropwise to the gelatin solution at a rate of 50mL / min, stir and react in a reactor at 50°C for 4h, then add 40L of deionized water at 50°C to dilute the reaction solution, and carry out ultra- Filtrate for 8 hours, use a filter membrane of 8 kDa, place the filtrate in a -80°C refrigerator overnight, and freeze-dry for 3 days to obtain methacrylamide-based gelatin with a modification degree of 75%.

[0064] (2) Configure 1 L of Irgacure 2959 aqueous solution with a mass concentration of 0.5 wt%, place it in a constant temperature water bath at 30°C and stir to dissolve, take 200 g of lyophilized methacrylamide-based gelatin and stir to dissolve, then add polyethylene glycol diacryla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com