Guar gum modified vinyl acetate low-solid and high-viscosity pressing plate adhesive and preparation method thereof

A vinyl acetate, guar gum technology, applied in the direction of adhesives, non-polymer adhesive additives, non-polymer organic compound adhesives, etc., can solve the problem of prolonged production process time, low solid content, and easy starch mold. and other problems, to achieve the effect of accelerating the water solubility, increasing the dispersion force, and improving the hydrophilicity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

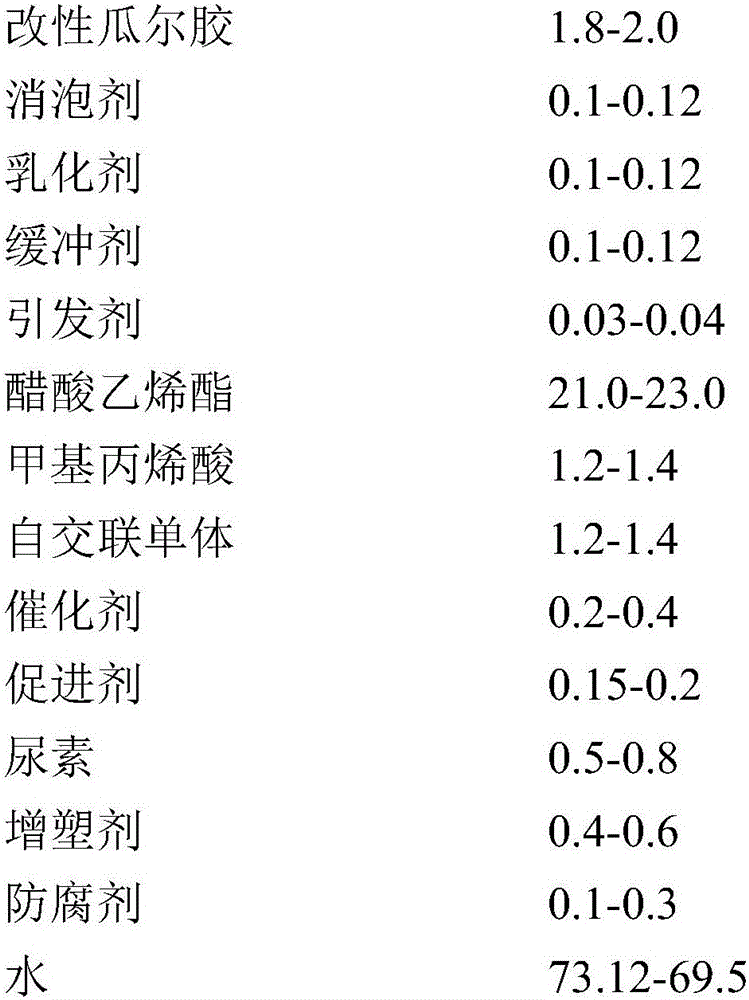

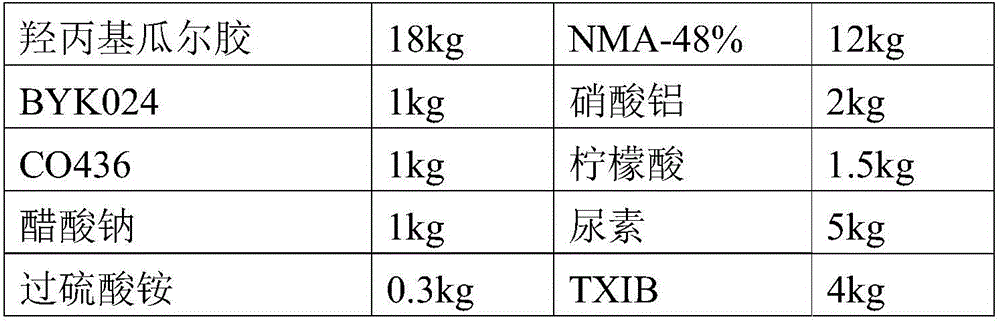

[0019] Formula: total amount = 1000kg

[0020]

[0021]

[0022] Production Process:

[0023] a. Dissolve 0.3kg of ammonium persulfate in 9.7kg of water to obtain 10kg of ammonium persulfate solution; disperse 12kg of NMA-48% in 12kg of water to obtain 24kg of NMA aqueous solution; add 210kg of vinyl acetate and 12kg of methacrylic acid to the monomer tank The tank is mixed and stirred evenly to make 222kg mixed monomer;

[0024] b. Add the remaining 709.5kg of water into the reactor, start stirring, add 1kg BYK024, 1kgCO436, 1kg sodium acetate, 18kg hydroxypropyl guar gum, heat up to 60°C, stir and disperse for 90 minutes to fully dissolve the hydroxypropyl guar gum ;

[0025] c. Warm up to 72°C, add 4kg of ammonium persulfate solution prepared in step a, then add dropwise 222kg of mixed monomer prepared in step a and the remaining 6kg of ammonium persulfate solution at the same time, control the mixed monomer to drop in 3.0 hours, and persulfate The ammonium solutio...

Embodiment 2

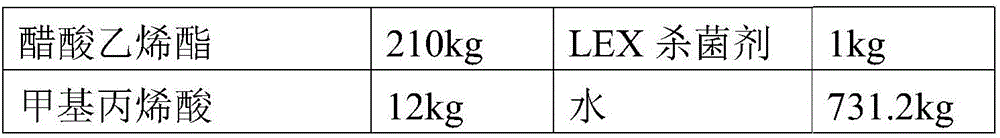

[0027] Embodiment two formula: total amount=1000kg

[0028] Hydroxypropyl Guar Gum 19kg NMA - 48% 13kg BYK024 1.1kg Aluminum nitrate 3kg CO436 1.1kg citric acid 1.8kg Sodium acetate 1.1kg urea 6kg Ammonium persulfate 0.3kg TXIB 5kg vinyl acetate 220kg LEX fungicide 2kg Methacrylate 13kg water 713.6kg

[0029] Production Process:

[0030] a. Dissolve 0.3kg of ammonium persulfate in 9.7kg of water to obtain 10kg of ammonium persulfate solution; disperse 13kg of NMA-48% in 13kg of water to obtain 26kg of NMA aqueous solution; add 220kg of vinyl acetate and 13kg of methacrylic acid to the monomer tank The tank is mixed and stirred evenly to make 233kg mixed monomer;

[0031] b. Add the remaining 690.9kg of water into the reaction kettle, start stirring, add 1.1kg BYK024, 1.1kgCO436, 1.1kg sodium acetate, 19kg hydroxypropyl guar gum, heat up to 60°C, stir and disperse for 90 minutes to make hydrox...

Embodiment 3

[0034] Embodiment three formula: total amount=1000kg

[0035] Hydroxypropyl Guar Gum 20kg NMA - 48% 14kg BYK024 1.2kg Aluminum nitrate 4kg CO436 1.2kg citric acid 2kg Sodium acetate 1.2kg urea 8kg Ammonium persulfate 0.4kg TXIB 6kg vinyl acetate 230kg LEX fungicide 3kg Methacrylate 14kg water 695kg

[0036] Production Process:

[0037] a. Dissolve 0.4kg of ammonium persulfate in 13kg of water to obtain 13.4kg of ammonium persulfate solution; disperse 14kg of NMA-48% in 14kg of water to obtain 28kg of NMA aqueous solution; add 230kg of vinyl acetate and 14kg of methacrylic acid into the monomer tank The tank is mixed and stirred evenly to make 244kg mixed monomer;

[0038]b. Add the remaining 668kg of water into the reaction kettle, start stirring, add 1.2kg BYK024, 1.2kgCO436, 1.2kg sodium acetate, 20kg hydroxypropyl guar gum, heat up to 60°C, stir and disperse for 90 minutes to make hydroxyp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com