High-strength bonding room temperature curing organosilicone potting adhesive for LED (light-emitting diode) and preparation method of adhesive

A technology of silicone potting glue and room temperature curing, which is applied in the direction of polymer adhesive additives, adhesives, adhesive additives, etc., can solve the problems that the mechanical properties are not up to LED packaging, easy to break, etc., and achieve simple process steps, Effects of improving mechanical properties and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

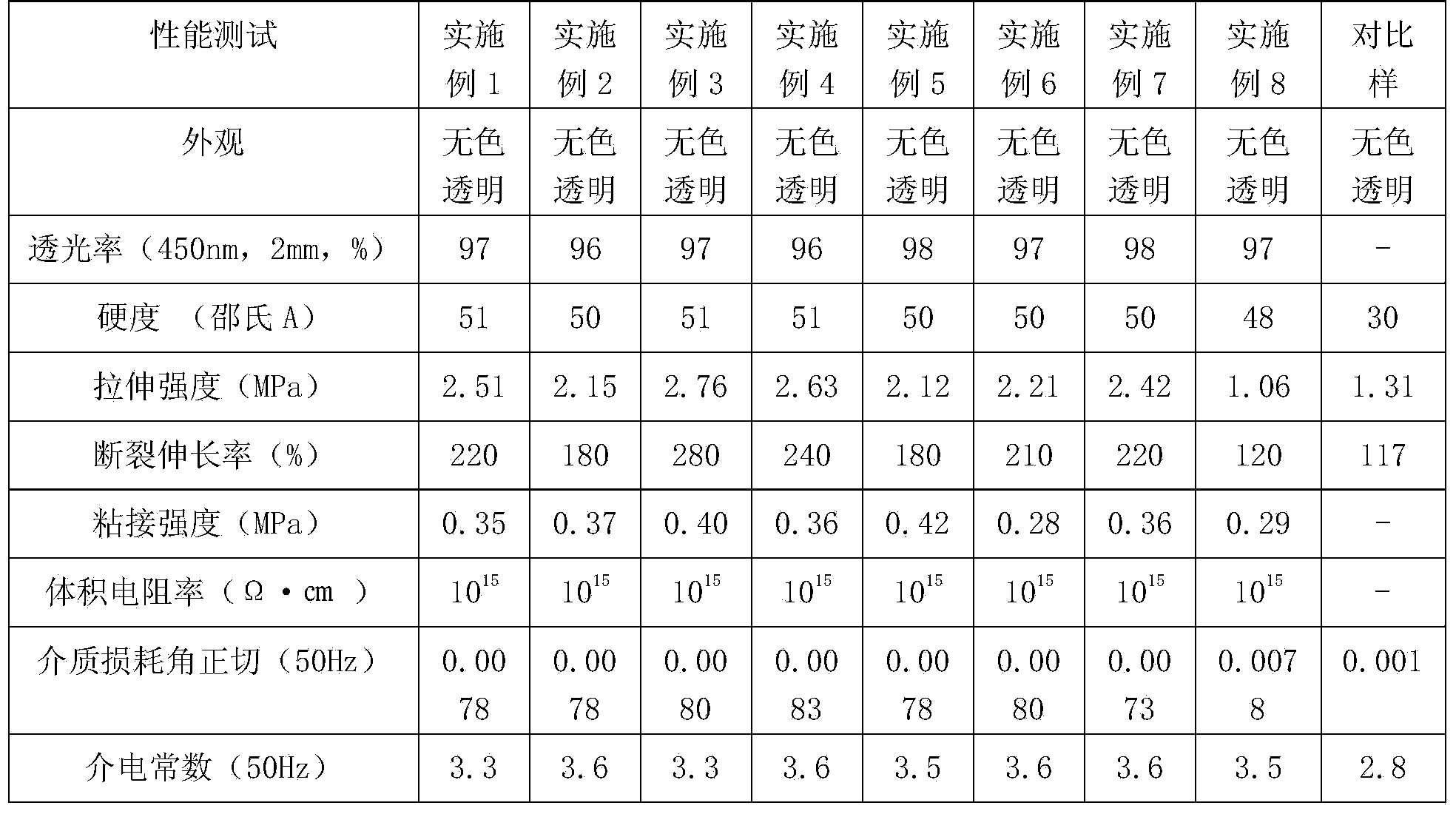

Examples

Embodiment 1

[0028] Mix tetramethylcyclotetrasiloxane, allyl glycidyl ether and vinyl trimethoxysilane in a weight ratio of 100:30:40, react at 20°C for 3 hours, and then react at 80°C for 1 hours, and then distilled off the small molecules at a temperature of 60°C and a pressure of -0.1 MPa to obtain a viscous viscous thickener in the form of light yellow oil.

[0029] Preparation of high-strength adhesive room temperature curing silicone potting compound for LED:

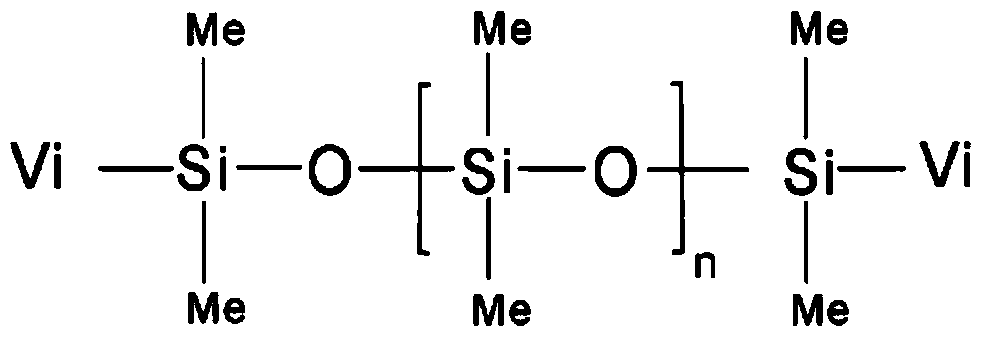

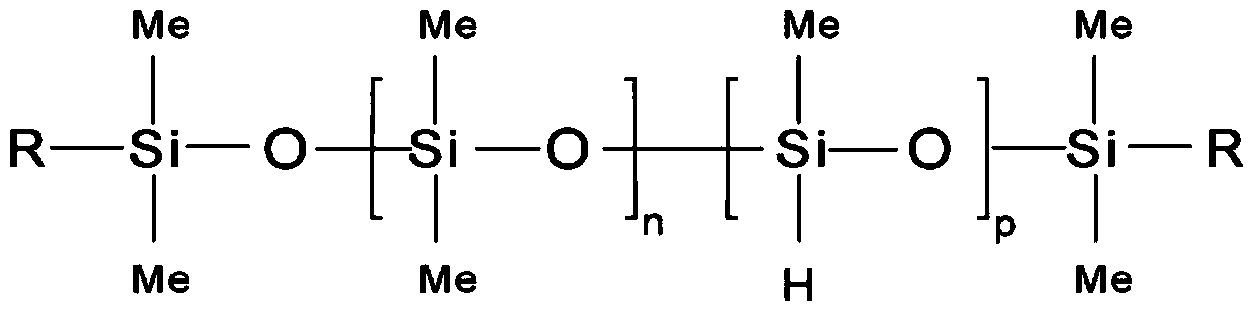

[0030] The encapsulant includes components A and B, wherein component A consists of vinyl-terminated silicone oil with a vinyl mass fraction of 0.16%, hydrogen-containing silicone oil with an active hydrogen mass fraction of 0.3%, and vinyl-terminated silicone oil with a vinyl mass fraction of 4%. Methyl vinyl MQ silicone resin is mixed at a weight ratio of 100:25:15 and packaged; component B consists of vinyl-terminated silicone oil with a vinyl mass fraction of 0.16%, methyl vinyl with a vinyl mass fraction of 4% Vinyl MQ s...

Embodiment 2

[0037] Mix tetramethylcyclotetrasiloxane, allyl glycidyl ether, and vinyltrimethoxysilane in a weight ratio of 100:70:80, react at 30°C for 2 hours, and then react at 60°C 2 hours. Then, the small molecules were distilled off at a temperature of 30°C and a pressure of -0.5 MPa to obtain a viscous viscous thickener in the form of light yellow oil.

[0038] Preparation of high-strength adhesive room temperature curing silicone potting compound for LED:

[0039] The encapsulant includes components A and B, wherein component A consists of vinyl-terminated silicone oil with a vinyl mass fraction of 0.23%, hydrogen-containing silicone oil with an active hydrogen mass fraction of 1.6%, and vinyl-terminated silicone oil with a vinyl mass fraction of 3%. Methyl vinyl MQ silicone resin is mixed at a weight ratio of 100:10:20 and packaged; component B consists of vinyl-terminated silicone oil with a vinyl mass fraction of 0.23%, and methyl vinyl with a vinyl mass fraction of 3%. Vinyl ...

Embodiment 3

[0046] Tetramethylcyclotetrasiloxane, allyl glycidyl ether, vinyltrimethoxysilane, and then the above raw materials were mixed uniformly in a weight ratio of 100:30:80, and reacted at 40°C for 1 hour. The reaction was further carried out at 70° C. for 3 hours. Then, the small molecules were distilled off at a temperature of 10°C and a pressure of -0.3 MPa to obtain a viscous viscous thickener in the form of light yellow oil.

[0047] The encapsulant includes components A and B, wherein component A consists of vinyl-terminated silicone oil with a vinyl mass fraction of 0.3%, hydrogen-containing silicone oil with an active hydrogen mass fraction of 0.5%, and vinyl-terminated silicone oil with a vinyl mass fraction of 2.7%. Methyl vinyl MQ silicone resin is mixed at a weight ratio of 100:55:25 and packaged; component B consists of vinyl-terminated silicone oil with a vinyl mass fraction of 0.3%, methyl vinyl with a vinyl mass fraction of 2.7% Vinyl MQ silicone resin, catalyst, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com