Water-based acrylic resin anti-corrosive insulation coating and preparation method of anti-corrosive insulation coating

A technology of water-based acrylic and insulating coatings, applied in the direction of epoxy resin coatings, anti-corrosion coatings, coatings, etc., can solve the problems of easy corrosion, poor water resistance, foaming, etc., to increase cross-linking points, improve water resistance and water resistance Corrosion and other properties, the effect of enhancing activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

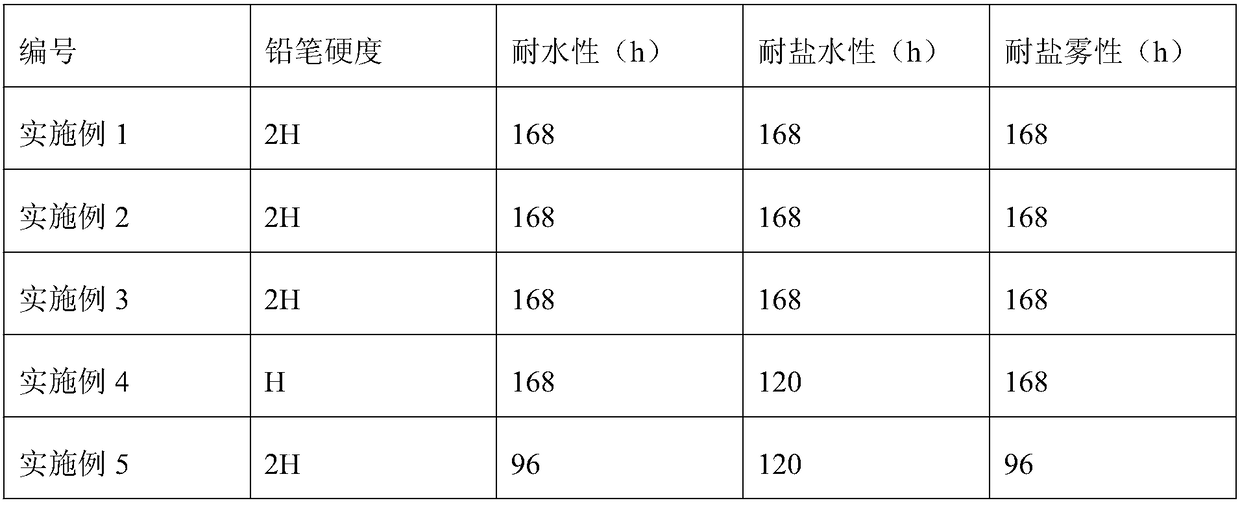

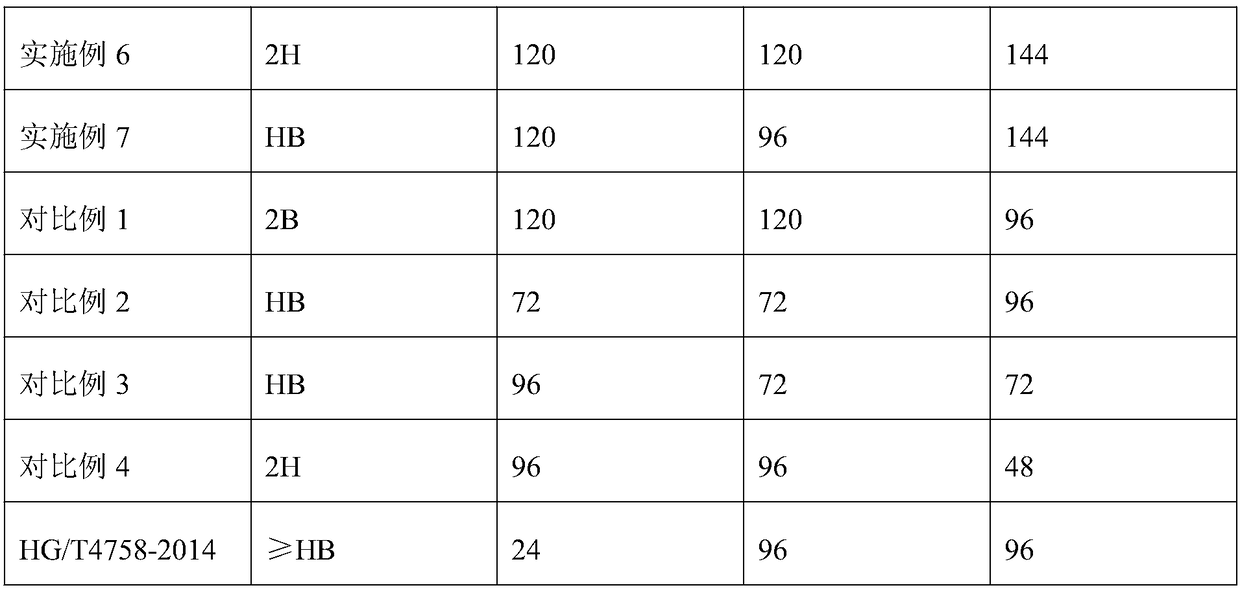

Examples

preparation example Construction

[0021] The invention provides a kind of preparation method of waterborne acrylic resin antirust insulating coating, wherein, comprise the following steps:

[0022] 1) In the presence of an initiator, mix octamethylcyclotetrasiloxane and divinyltetramethyldisiloxane under a nitrogen atmosphere and react at a temperature of 100-170°C to obtain Premix X1;

[0023] 2) In the presence of a solvent, stir and mix the epoxy resin and the premix X1 with the modification accelerator to prepare the modified epoxy resin X2;

[0024] 3) mixing water-based acrylic resin, modified epoxy resin X2, filler, azobisisobutyronitrile and water and then grinding to prepare water-based acrylic resin anti-rust insulating coating;

[0025] Wherein, the filler includes at least calcium carbonate and zinc phosphate.

[0026] The present invention has the following beneficial effects: the present invention catalyzes octamethylcyclotetrasiloxane in the presence of an initiator, forms an activation center...

Embodiment 1

[0038] 1) Under a nitrogen atmosphere, put 800mL of octamethylcyclotetrasiloxane and 1mL of tetramethylammonium hydroxide at a temperature of 50°C and stir and mix for 1 hour, then add 700mL of divinyltetramethyldisiloxane Stir and mix the alkanes at 70°C for 0.5h, then raise the temperature to 150°C, stir and mix for 3h, then distill under reduced pressure to obtain the premix X1;

[0039] 2) Stir and mix 10mL cyclohexanone, 5g epoxy resin, 3g premix X1 and 0.2mL n-tetrabutyl titanate at 150°C to prepare modified epoxy resin X2;

[0040] 3) After mixing 100g of water-based acrylic resin, 30g of modified epoxy resin X2, 10g of filler (the weight ratio of calcium carbonate: zinc phosphate: nano-titanium dioxide is 1:0.3:0.05), 2g of azobisisobutyronitrile and 30mL of water Grind to obtain the water-based acrylic resin antirust insulating coating A1.

Embodiment 2

[0042] 1) Under a nitrogen atmosphere, put 1100mL of octamethylcyclotetrasiloxane and 1mL of tetramethylammonium hydroxide at a temperature of 60°C and stir and mix for 2 hours, then add 800mL of divinyltetramethyldisiloxane Stir and mix the alkanes at 80°C for 1 hour, raise the temperature to 170°C, stir and mix for 5 hours, then distill under reduced pressure to obtain the premix X1;

[0043] 2) Stir and mix 10mL cyclohexanone, 20g epoxy resin, 8g premix X1 and 1mL n-tetrabutyl titanate at 170°C to prepare modified epoxy resin X2;

[0044] 3) After mixing 100g of water-based acrylic resin, 50g of modified epoxy resin X2, 20g of filler (the weight ratio of calcium carbonate: zinc phosphate: nano-titanium dioxide is 1:0.6:0.08), 5g of azobisisobutyronitrile and 50mL of water Grind to obtain the water-based acrylic resin antirust insulating coating A2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com