High-branching-degree water-based saturated polyester modified acrylic resin, preparation method thereof and water-based gloss oil for metal

A technology of water-based polyester resin and acrylic resin, which is applied in the direction of coating, etc., can solve the problems of inability to produce high-branched modified resin, insufficient retort resistance and wear resistance, etc., achieve excellent chemical resistance, improve Eco-friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

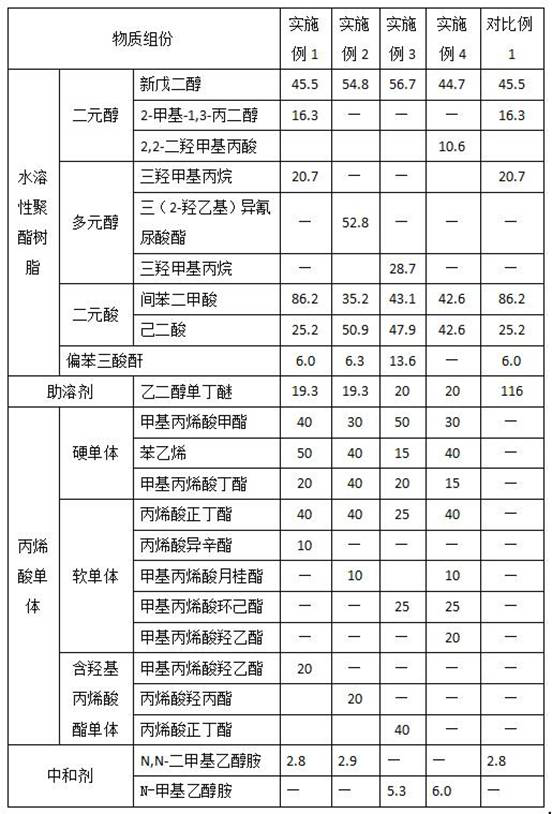

Embodiment 1

[0055] Put 45.5g of neopentyl glycol, 20.7g of trimethylolpropane, 86.2g of isophthalic acid, 25.2g of adipic acid, and 16.3g of 2-methyl-1,3-propanediol into the reaction flask; raise the temperature to 140°C and keep it warm to 1 hour; 2 hours to raise the temperature of the material to 180 for reaction, and keep it for 2 hours; within 3 hours, raise the temperature to 230±3°C and keep it for 3 hours, start sampling and test until the acid value is ≤10; cool down to 170°C, add 6.0g of trimellitic anhydride, keep it for 1h, Start sampling to test the acid value, and the acid value is 25 as the reaction end point; cool down to 150°C, add 19.3g of ethylene glycol monobutyl ether to dilute; continue to cool down to 70°C. Then add 40 g of methyl methacrylate, 50 g of styrene, 20 g of butyl methacrylate, 40 g of n-butyl acrylate, 10 g of isooctyl acrylate, and 20 g of hydroxyethyl methacrylate, and stir for 30 minutes. Add 2.8g of N,N-dimethylethanolamine and stir for 20min. Cont...

Embodiment 2

[0058] Put 54.8g of neopentyl glycol, 52.8g of tris(2-hydroxyethyl)isocyanurate (THEIC), 35.2g of isophthalic acid, and 50.9g of adipic acid into the reaction flask; 1 hour; within 2 hours, raise the temperature of the material to 180°C for reaction, and keep it for 2 hours; within 3 hours, raise the temperature to 230±3°C and keep it for 3 hours, start sampling and test until the acid value is ≤10; cool down to 170°C, add 6.3g of trimellitic anhydride, hold it for 1h, start Sampling was taken to test the acid value, and the acid value was 25 as the reaction end point; the temperature was lowered to 150°C, and 19.3g of ethylene glycol monobutyl ether was added to dilute; the temperature was further lowered to 70°C. Then add 30g of methyl methacrylate, 40g of styrene, 40g of butyl methacrylate, 40g of n-butyl acrylate, 10g of lauryl methacrylate, 20g of hydroxypropyl acrylate, and stir for 30min. Add 2.9 g of N,N-dimethylethanolamine and stir for 20 min. Control the temperatur...

Embodiment 3

[0061] Put 56.7g of neopentyl glycol, 28.7g of trimethylolpropane, 43.1g of isophthalic acid, and 47.9g of adipic acid into the reaction bottle; raise the temperature to 140°C and keep it warm for 1 hour; raise the temperature of the material to 180°C in 2 hours Reaction, keep warm for 2 hours; within 3 hours, heat up to 230±3°C and keep warm for 3 hours, start sampling and testing until the acid value is ≤10; cool down to 170°C, add 13.6g of trimellitic anhydride, keep warm for 1h, start sampling and testing the acid value, the acid value is 45 for the reaction End point; cool down to 150°C, add 20g of ethylene glycol monobutyl ether to dilute; continue to cool down to 70°C. Then add 50 g of methyl methacrylate, 15 g of styrene, 20 g of butyl methacrylate, 25 g of cyclohexyl methacrylate, 40 g of n-butyl acrylate, 10 g of isooctyl acrylate, and 20 g of hydroxypropyl acrylate, and stir for 30 minutes. Add 5.3 g of N-methylethanolamine and stir for 20 min. Control the temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com