Low permanent compression deformation thermoplastic polyurethane elastomer

A thermoplastic polyurethane and permanent deformation technology, applied in the field of thermoplastic polyurethane elastomers, can solve problems such as unsatisfactory effects and complicated methods, and achieve the effects of increasing service life, enhancing pressure resistance, improving durability and usability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

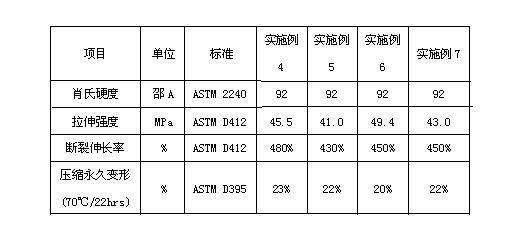

Examples

Embodiment 1

[0035] In Example 1, the raw materials used are the following components, and each component is in mass fraction:

[0036] Diphenylmethane 4,4’-diisocyanate (MDI) 564g

[0037] 1,4-butanediol adipate (PBA) (molar mass 2000g / mol) 1000 grams

[0038] 1,4-Butanediol (BDO) (molar mass is 90.123g / mol, functionality is 2) 151 grams

[0039] Trimethylolpropane (TMP) (molar mass 134g / mol, functionality 3) 1.0 g

[0040] Catalyst: Stannous octoate 0.01g

[0041] Antioxidant: Irganox ? 1010 3 grams

[0042] A mixture of 1000 grams of PBA, 151 grams of BDO and 3 grams of TMP is heated to 90°C, and then 3 grams of Irganox are added ? 1010 and 0.01 g of stannous octoate were stirred with a paddle mixer at a speed of 500 revolutions per minute, and then 564 g of MDI was added, the mixture was continued to be stirred for 20 seconds, and then poured onto a metal tray coated with polytetrafluoroethylene; The cured product is placed in an oven at 80°C for 24 hours, then crushed an...

Embodiment 2

[0043] In Example 2, the raw materials used are the following components, and each component is in mass fraction:

[0044] Diphenylmethane 4,4’-diisocyanate (MDI) 564g

[0045] 1,4-butanediol adipate (PBA) (molar mass is about 2000g / mol) 1000 grams

[0046] 1,4-Butanediol (BDO) (molar mass is 90.123g / mol, functionality is 2) 77 g

[0047] Trimethylolpropane (TMP) (molar mass is 134g / mol, functionality is 3) 76.3 g

[0048] Catalyst: stannous octoate 0.01g

[0049] Antioxidant: Irganox ? 1010 3 grams

[0050] A mixture of 1000 grams of PBA, 77 grams of BDO and 76.3 grams of TMP is heated to 90°C, and then 3 grams of Irganox is added ? 1010 and 0.01 g of stannous octoate were stirred with a paddle mixer at a speed of 500 revolutions per minute, and then 564 g of MDI was added. The mixture was continued to be stirred for 20 seconds, and then poured onto a metal tray coated with PTFE to obtain The cured product is placed in an oven at 80°C for 24 hours and then ...

Embodiment 3

[0051] In Example 3, the raw materials used are the following components, and each component is in mass fraction:

[0052] Diphenylmethane 4,4’-Diisocyanate (MDI) 564g

[0053] Polyethylene adipate 1,4-butanediol-ester (PBA) (molar mass 2000g / mol) 1000 grams

[0054] 1,4-Butanediol (BDO) (molar mass is 90.123g / mol, functionality is 2) 143.3g

[0055] Placell ? 305 (molar mass is 550g / mol, functionality 3) 46g

[0056] Catalyst: stannous octoate 0.01g

[0057] Antioxidant: Irganox ? 1010 3g

[0058] Among them, Placell ? 305 is produced by Japanese Daicel

[0059] 1000g PBA and 143.3g BDO, 46g Placell ? The 305 mixture is heated to 90°C, then 3 grams of Irganox is added ? 1010 and 0.01 g of stannous octoate were stirred with a paddle mixer at a speed of 500 revolutions per minute, and then 564 g of MDI was added, the mixture was continued to be stirred for 20 seconds, and then poured onto a metal tray coated with polytetrafluoroethylene; The cured...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molar mass | aaaaa | aaaaa |

| molar mass | aaaaa | aaaaa |

| molar mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com