Preparation method of thermoplastic elastomer (TPE) alloy material for polyethylene terephthalate (PBT) bonding encapsulation

An alloy material and coating technology, applied in the field of TPE alloy material and its preparation, can solve the problems of unsatisfactory coating effect, poor adhesion of engineering plastic coating, easy peeling, etc. The effect of easy peeling and lowering of temperature due to poor force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the object, technical solution and advantages of the present invention clearer, the following examples further describe the present invention in detail. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

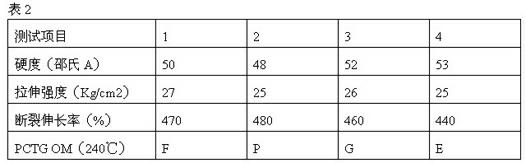

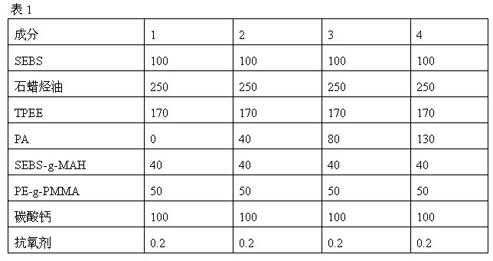

[0029] A TPE alloy material used for PBT bonding and encapsulation, in parts by weight, the composition ratio of the TPE alloy material is:

[0030] Thermoplastic elastomer 30~40 parts

[0031] Plasticizer 10~30 parts

[0032] Engineering plastic 15~30 parts

[0033] Compatibilizer 10~15 parts

[0034] Filling material 10~15 parts

[0035] Auxiliary 0.02~0.1 part.

[0036] Weigh the raw materials according to the above weight ratio; carry out corresponding pretreatment on the raw materials; uniformly mix thermoplastic elastomers, plasticizers, engineering plastics, compatibilizers, fillers, and additives and enter the twin-screw co-directional co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com