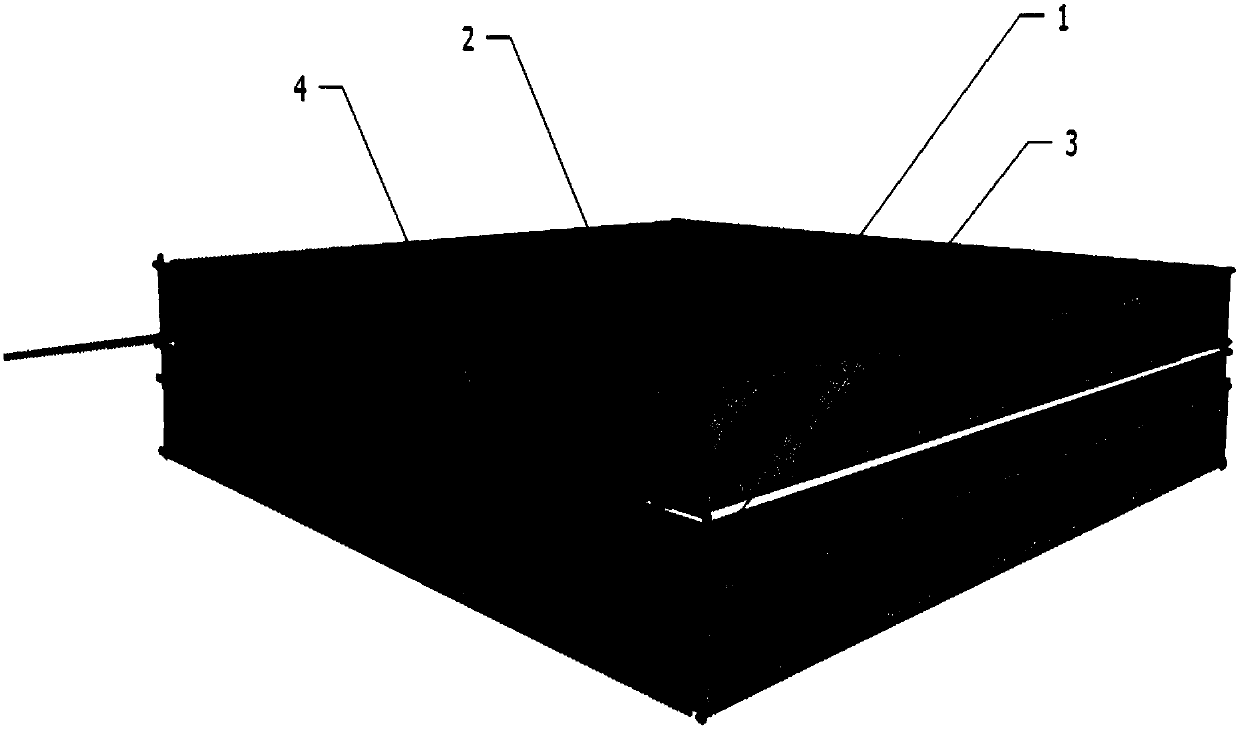

Flexible stress sensor based on carbon nanotube and silver nanowire composite conductive film

A stress sensor, composite conductive technology, applied in instruments, measuring forces, measuring devices, etc., can solve problems such as poor adhesion, and achieve the effects of improving conductivity, responsiveness, and adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

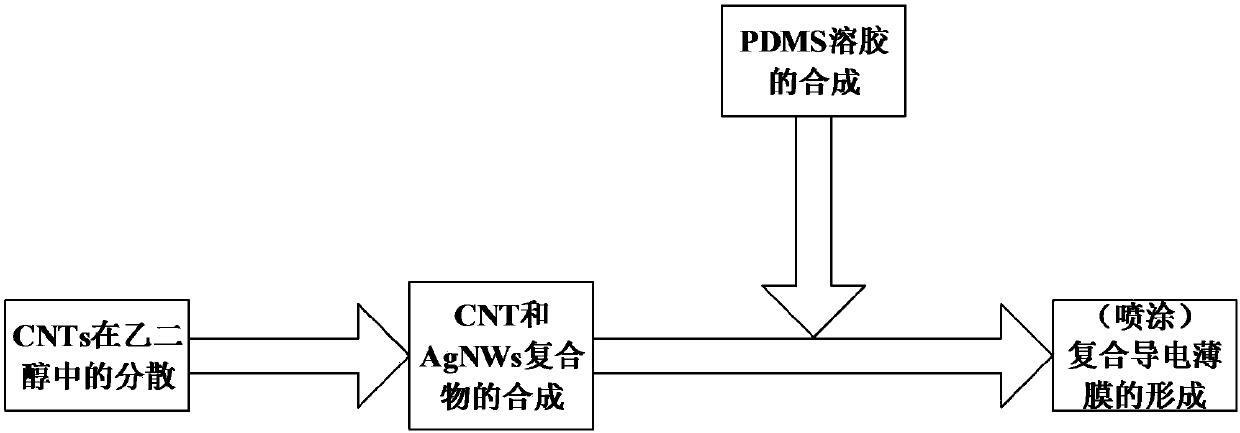

[0021] Step 1. Put 0.2g PVP and 0.012g CNTs into a grinding bowl for sufficient grinding. Pour the ground powder into a beaker containing 20 ml of ethylene glycol. Put it into an ultrasonic machine for ultrasonic dispersion for 12h-24h until the ultrasonic dispersion is uniform. Then dilute the ethylene glycol to 250ml, and then ultrasound for 12h-24h. Finally, the dispersed solution was allowed to stand still for 12 hours, and the precipitate-free solution with CNTs dispersed in the upper layer was taken.

[0022] Step 2. Weigh 0.108gAgNO 3 (Silver nitrate) and 0.1758g PVP are dissolved in 6ml of the upper sediment-free solution obtained in step 1, and continuously stirred to make it fully dissolved. In addition, weigh 0.02g of NaCl (sodium chloride) and dissolve it in 20ml of the upper layer solution obtained in step 1 without precipitation solution, and stir continuously to make it fully dissolved. Then measure 2ml of the above solution with NaCl dissolved, and the dissolve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com