Method for producing bentonite cat litter

A technology of bentonite and calcium-based bentonite, which can be used in animal houses, applications, animal husbandry, etc., can solve problems such as high cost and long production cycle, and achieve the effects of short production process, increased specific surface area, and improved water absorption.

Active Publication Date: 2010-08-25

INNER MONGOLIA UNIVERSITY

View PDF8 Cites 36 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, this method still has shortcomings such as long production cycle (attapulgite clay and magnesium oxide need to be in contact with each other and infiltrated for 24-48 hours, and the granulated cat litter particles need to be aired until the moisture content is less than or equal to 12%), and the cost is relatively high.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Login to View More

Abstract

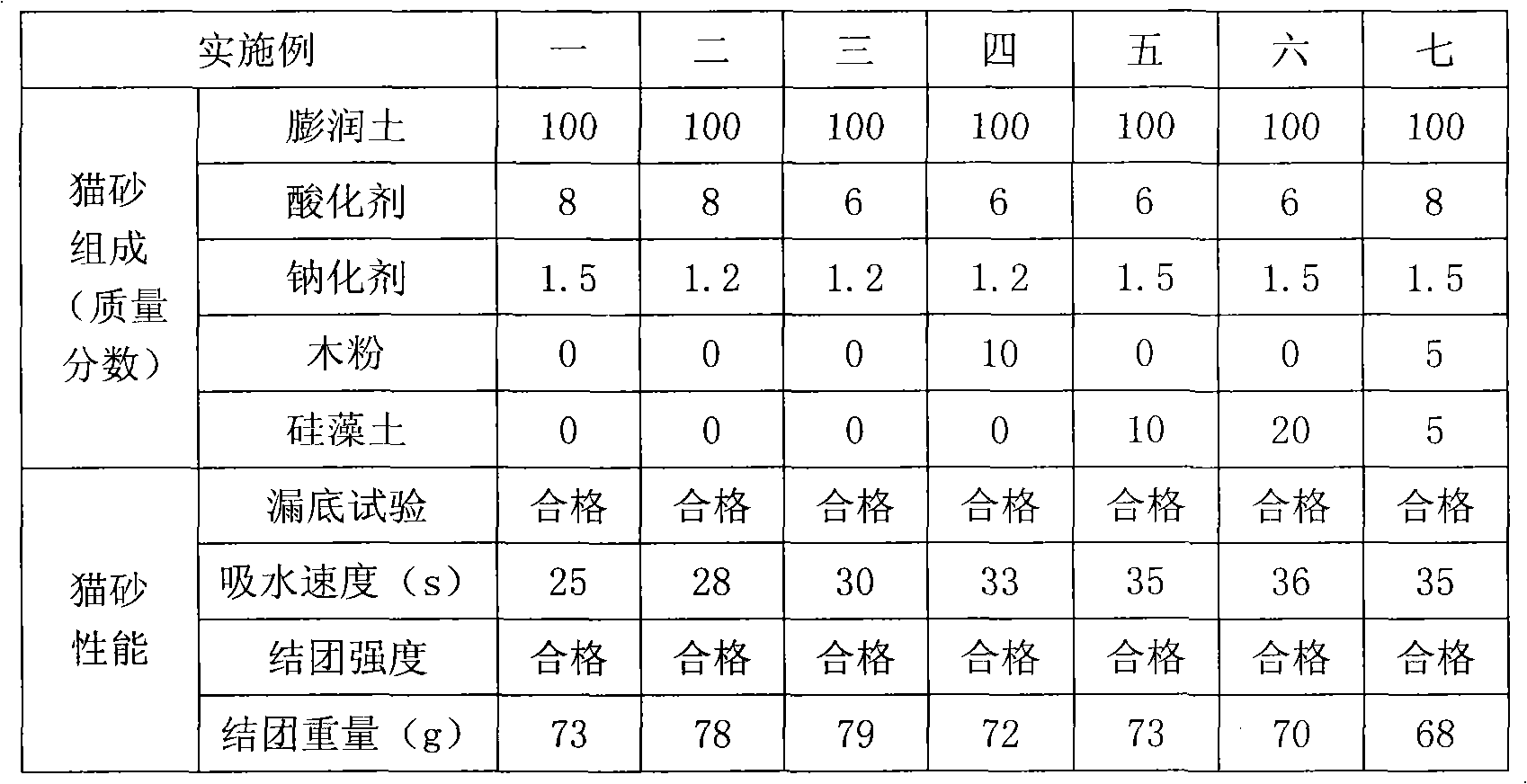

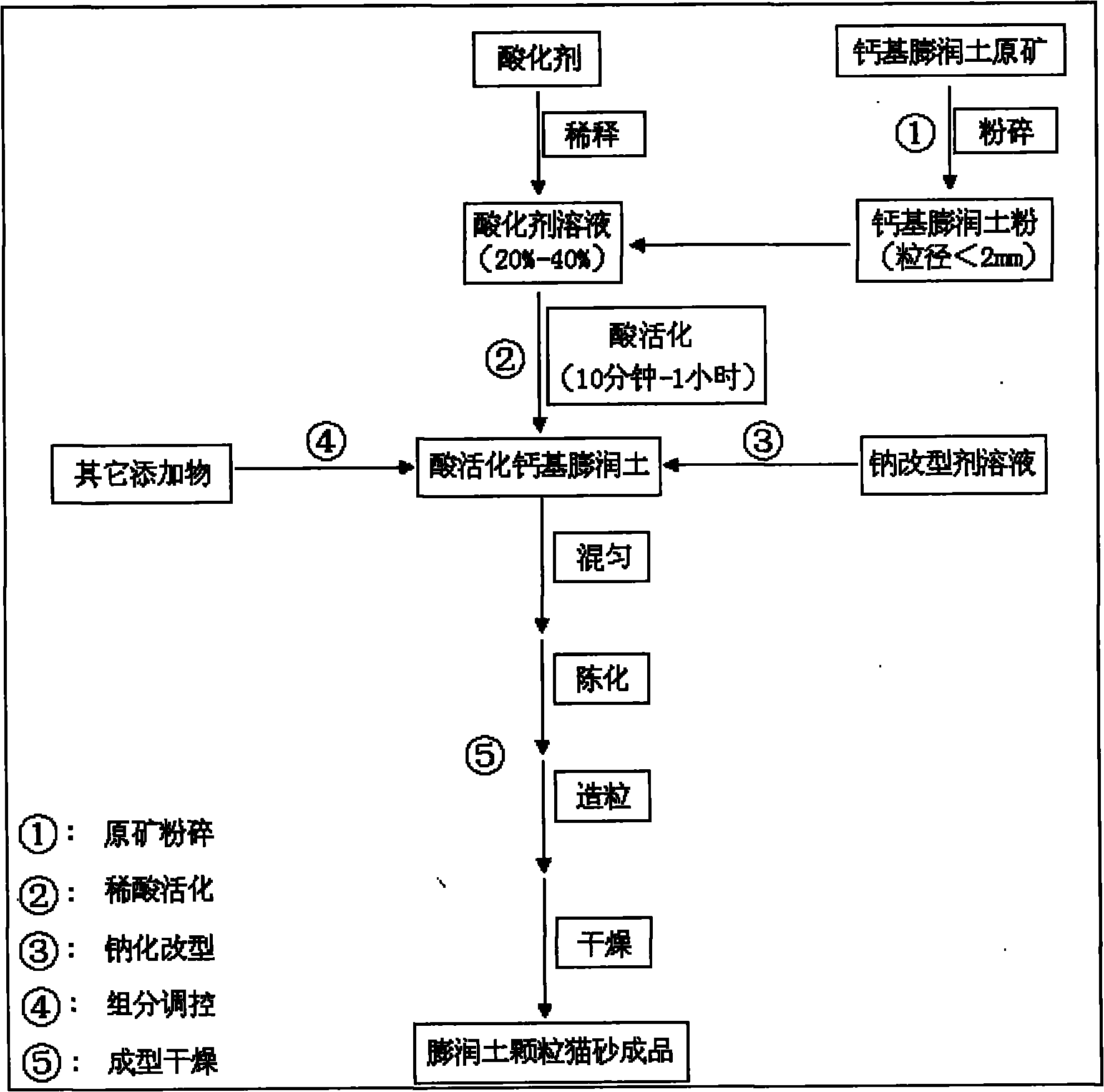

The invention discloses a method for producing bentonite cat litter by calcium-based bentonite. The method comprises the following steps of: grinding, acidification, sodium-modification, forming, drying and the like. In method, the calcium-based bentonite crude ores are used as a starting point, the bentonite slices are acidified and corroded by an acidifier so as to greatly increase a specific surface area of the bentonite, a sodium-modification agent is used for sodium-modification of the acidified calcium-based bentonite so as to improve a water absorption rate and bonding property of the bentonite, other additives such as wood flour and diatomite are added so as to adjust indexes, such as density and whiteness, of the cat litter, and finally the bentonite undergoes granulation, drying, screening and the like to form the bentonite cat litter having the advantages of quick water absorption, large amount of water absorption, high whiteness and high strength. The method has the advantages of good quality of the bentonite cat litter prepared by the method, simple process and low cost.

Description

technical field The invention relates to a bentonite cat litter production technology, in particular to a method for producing bentonite cat litter from natural calcium-based bentonite. Background technique Cat litter was invented by American H.Edward Lowe in 1947. It is an excrement place provided by people to satisfy the habit of cats covering their excrement with sand. Although theoretically all substances with water absorption can be used to make cat litter, such as silica gel, wood powder, rice husk, etc.; but because of its low price, bentonite has excellent water absorption, coagulation, deodorization and properties It is more suitable for the nature of cats and other advantages, and has always been the most important raw material for making cat litter. Bentonite is a clay mainly composed of montmorillonite minerals, and each bentonite particle is composed of thousands of tiny montmorillonite crystal nanosheets. The montmorillonite crystal is composed of two layers...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): A01K1/015

Inventor 苏海全张兵兵苏越

Owner INNER MONGOLIA UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com