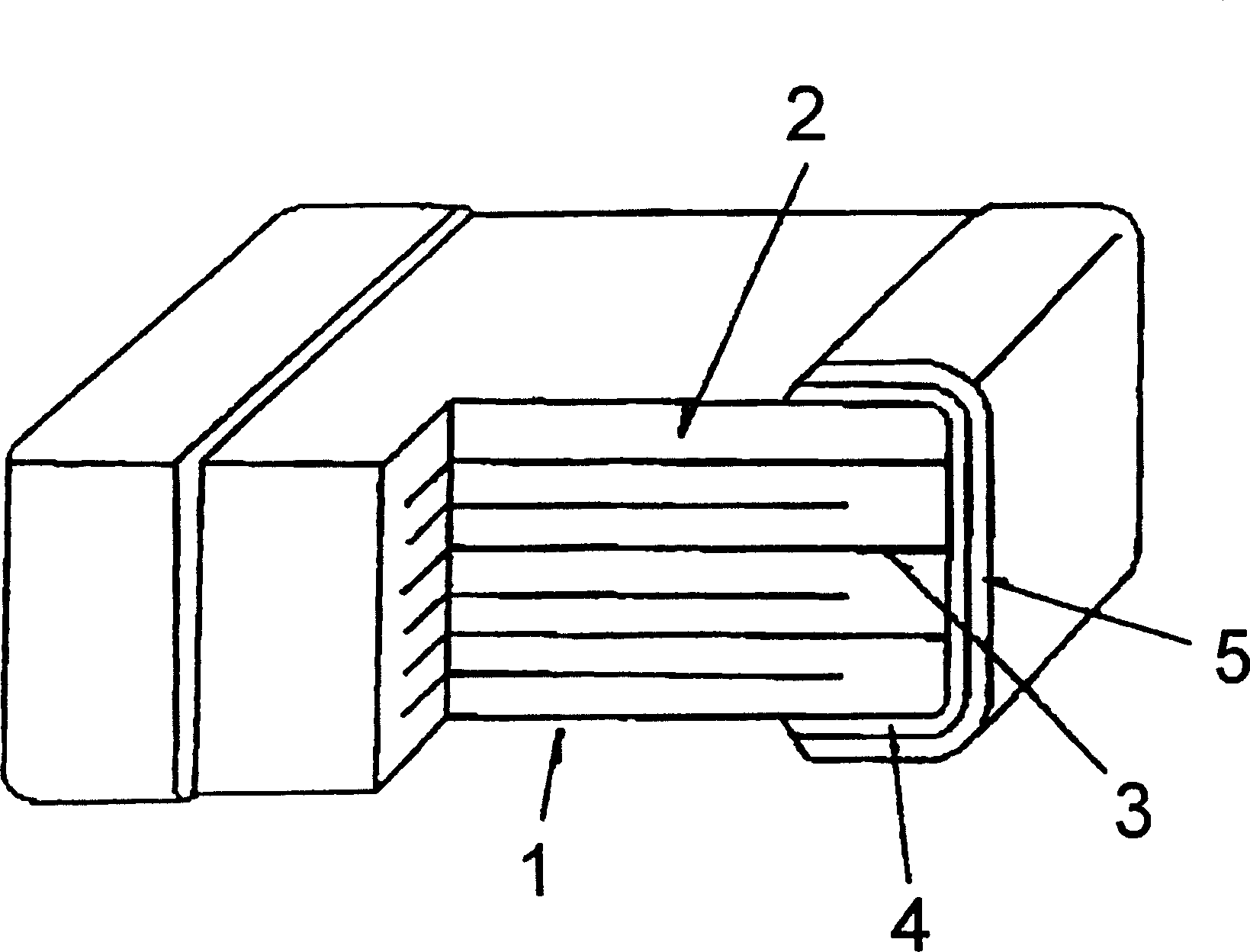

Electronic part with external electrode

A technology of electronic components and external electrodes, which is applied in the field of laminated ceramic electronic components, can solve problems such as poor plating, degradation of moisture-resistant life insulation, and inability to obtain electrical characteristics of electrostatic capacitance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0039] Hereinafter, the present invention will be described in further detail through examples and comparative examples. The present invention is not limited by these examples. However, in these examples, parts represent parts by weight.

[0040] [Preparation of conductive paste]

[0041] The compositions of the conductive pastes used in Examples and Comparative Examples are shown in Table 1 below.

[0042] Conductive paste

A

(fired type)

B

C

Spherical silver powder A

50

-

-

Spherical silver powder B

-

75

55

Flake silver powder C

25

-

-

Flake silver powder D

-

10

15

5

-

-

tin powder

-

-

15

3.5

-

-

Resole type phenolic resin

-

9.5

9.5

Embodiment 1

[0050] Example 1 (production of thermosetting electrode)

[0051] Under the conditions of Comparative Example 2, the conductive paste C (thermosetting) shown in Table 1 was applied, dried, cured, and plated to obtain a chip multilayer capacitor.

[0052] [determination]

[0053] The chip multilayer capacitor element obtained above is placed on the Pb-free solder paste printed on the copper-clad electrode of the glass epoxy substrate, and the solder paste is fully melted at a temperature such as 250 to 260°C. Solder joints were used to prepare test samples for electrical characteristics and joint strength. Measure the initial electrical properties (capacitance, tan δ) of the sample with 4278A manufactured by Agilent, measure the bonding strength (shear strength) with the substrate electrode with a bench-top strength tester manufactured by AIKOHENGINEERING CO., LTD, and then measure the thermal cycle resistance in the same way Electrical characteristics and joint strength afte...

Embodiment 1a~1d

[0058] In order to study the situation of changing the compounding amount of conductive particles with a high melting point and metal powder with a melting point below 300°C in the thermosetting conductive paste, the composition shown in Table 3 below was used to prepare the heat Curable conductive paste. The amount of conductive particles with a high melting point and metal powder with a melting point below 300°C in the thermosetting conductive paste is 60 to 98% relative to the total weight of conductive particles with a high melting point, metal powder with a melting point below 300°C, and resin. weight%. Furthermore, using the prepared paste, capacitor samples were prepared in the same manner as in Example 1, and their electrical characteristics and joint strength were measured.

[0059] The capacitors obtained in Examples 1a to 1d are the same as in Example 1, showing good electrical properties and joint strength, especially when the high melting point conductive particles...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com