Method for visually monitoring fracture crack

A fracturing and fracture technology, applied in the field of visual monitoring of fracturing fractures, can solve problems such as high cost, fracture development and damage, and damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

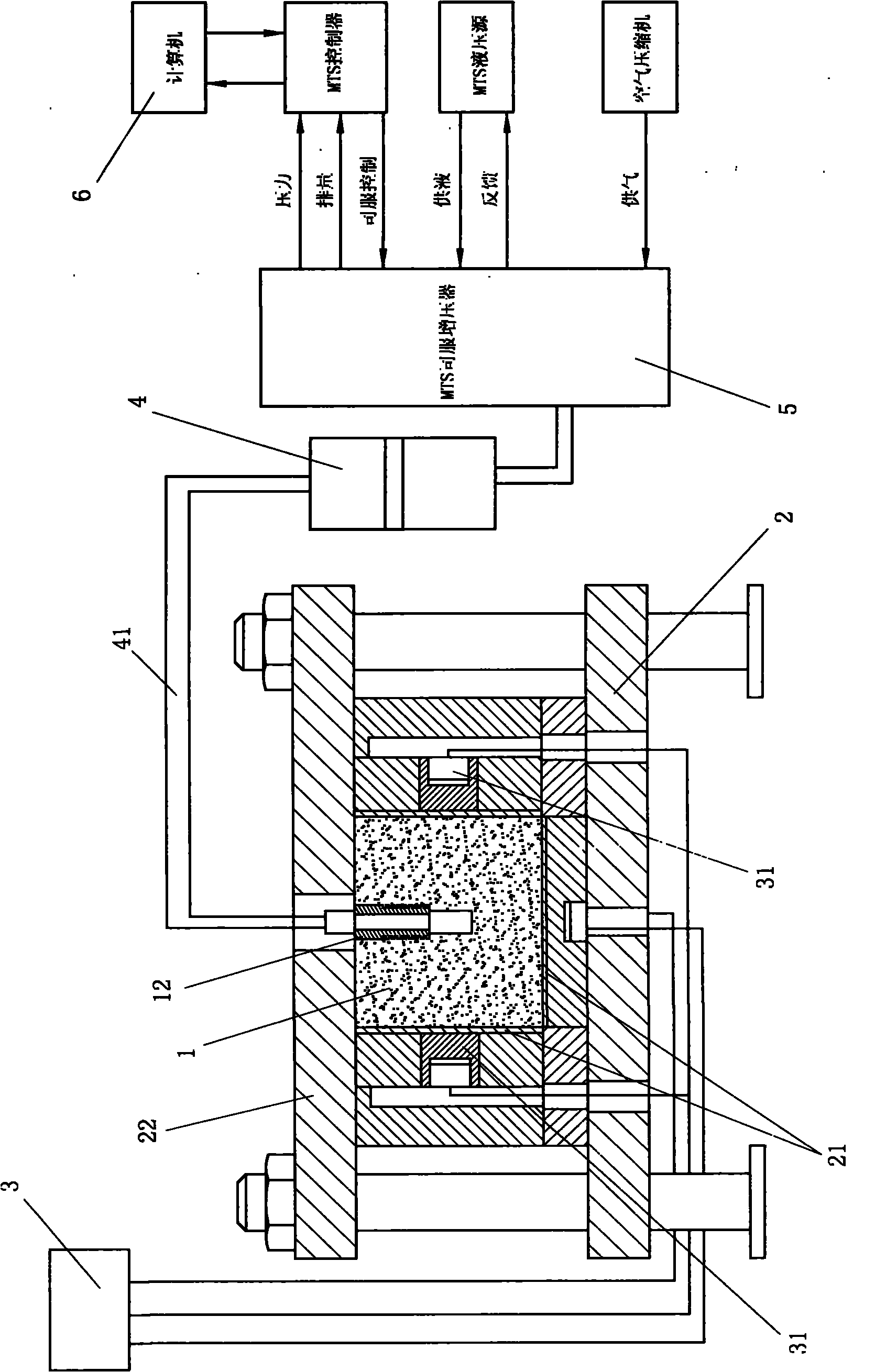

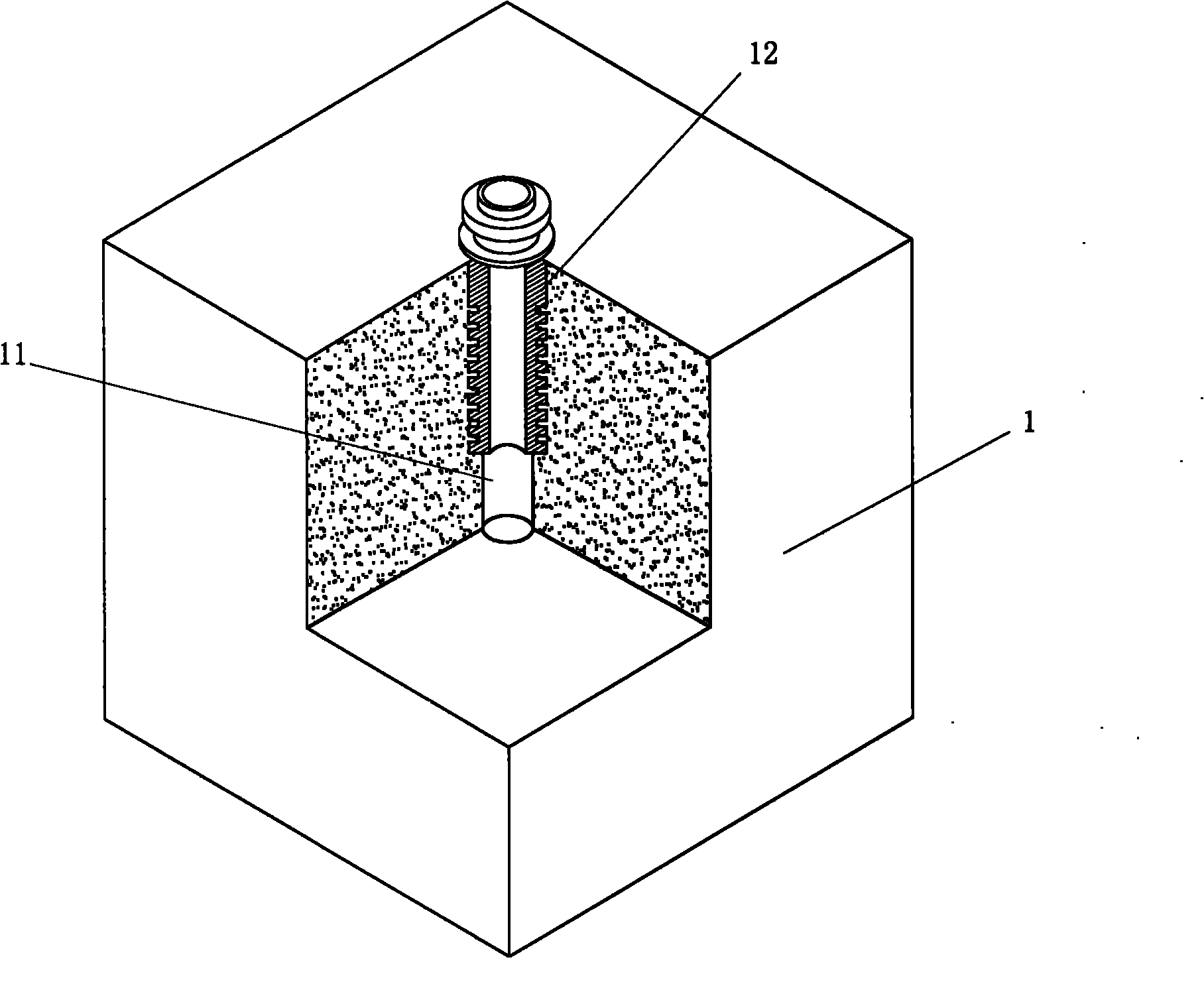

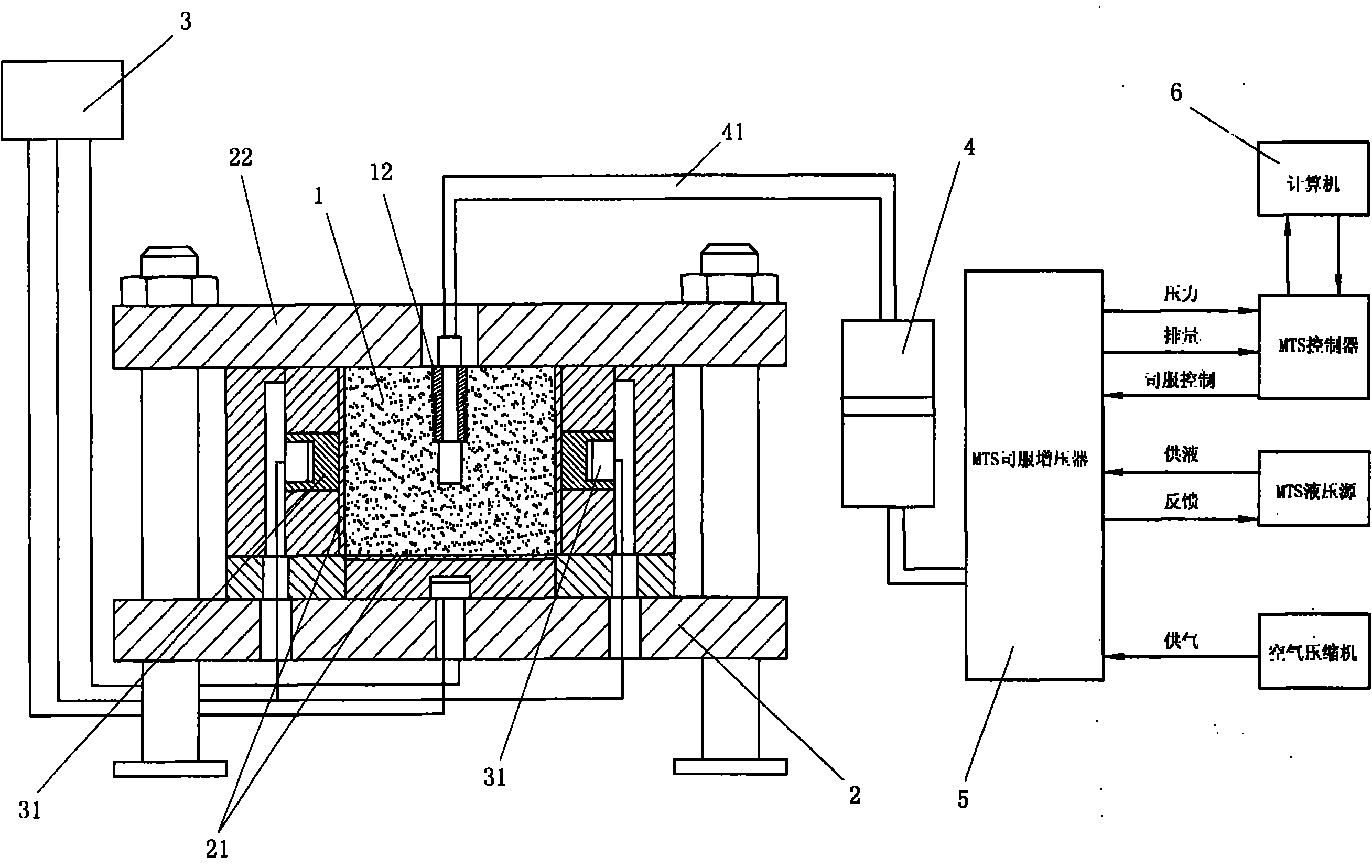

[0029] The present invention proposes a method for visually monitoring fracturing fractures. The method uses a room-temperature-curable fluid material as a fracturing fluid, injects the fluid material into a simulated wellbore of a core sample, and generates cracks when the core sample is fractured. At the same time, the room temperature curing fluid material is filled into the crack and filled with the crack, and after the room temperature curing fluid material is solidified to form a simulated crack, the simulated crack is taken out and the shape of the simulated crack is observed;

[0030] In this embodiment, the room temperature curing fluid material is a two-component liquid silica gel at room temperature; the two-component liquid silica gel at room temperature is composed of SYLGARD184 liquid silica gel mixed with a catalyst; the SYLGARD184 liquid silica gel has lower viscosity and Strong tensile strength, elongation at break and tear strength, operating time is 2 hours. ...

Embodiment approach 2

[0046] The principle and structure of this embodiment and Embodiment 1 are basically the same, the difference is that in this embodiment, silicone oil is injected into the simulated wellbore 12 of the core sample 1 as a fracturing fluid, and the core sample 1 is fractured to produce After the fracture, the room temperature solidifying fluid material (that is: the aforementioned room temperature two-component liquid silica gel) is injected as a filling material into the simulated wellbore 12 of the core sample 1, so that the liquid silica gel is filled into the fracture to replace the The silicone oil is filled with the cracks, and after the liquid silicone solidifies to form simulated cracks, the simulated cracks are taken out and the shape of the simulated cracks is observed.

[0047] In this embodiment, the silica gel used as the fracturing fluid is simethicone. The simethicone oil has physiological inertia, good chemical stability, electrical insulation and weather resistan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com