Cracking load determination method of concrete fracture test based on acoustic emission technique

An acoustic emission technology and crack initiation load technology, which is applied in the direction of testing the strength of materials by applying a stable bending force, and analyzing solids by using sound waves/ultrasonic waves/infrasonic waves, which can solve the problems of large test load values, large judgment errors, and nonlinear starting points Difficult to determine and other problems, to achieve the effect of the crack initiation load of the precise concrete fracture test

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Concrete Fracture Test Initiation Load Acoustic Emission Test Process

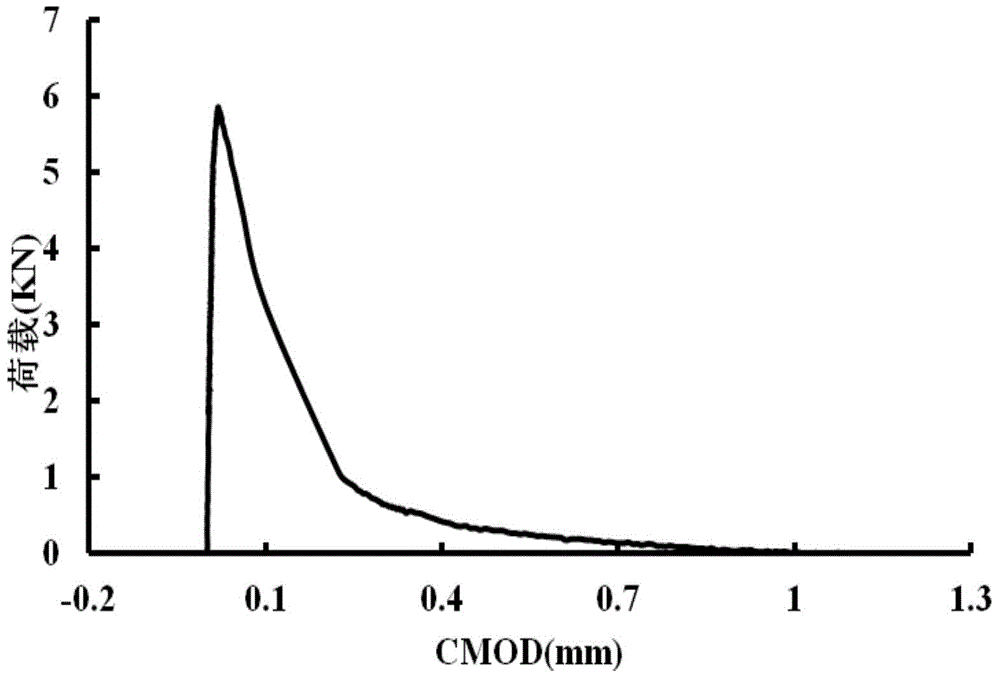

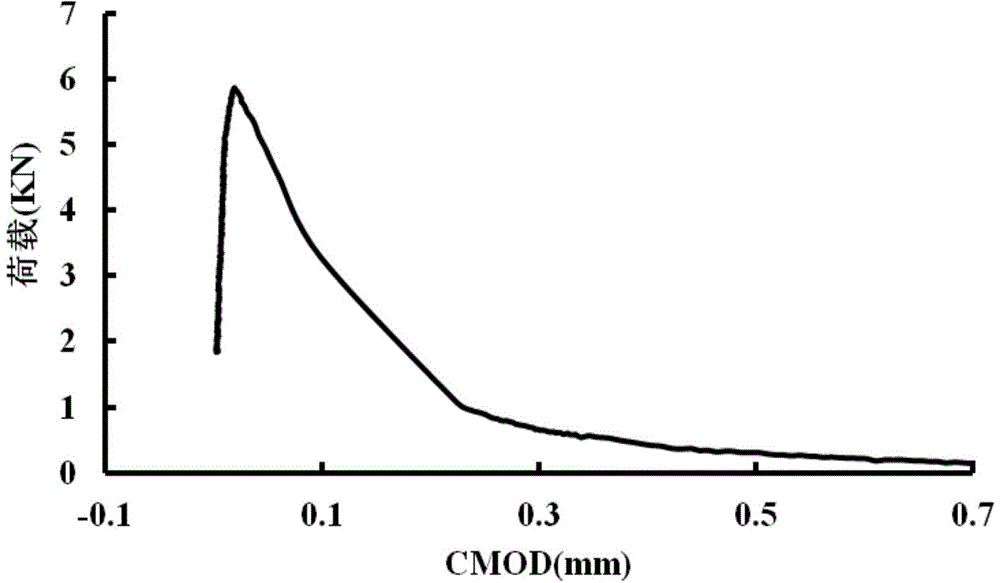

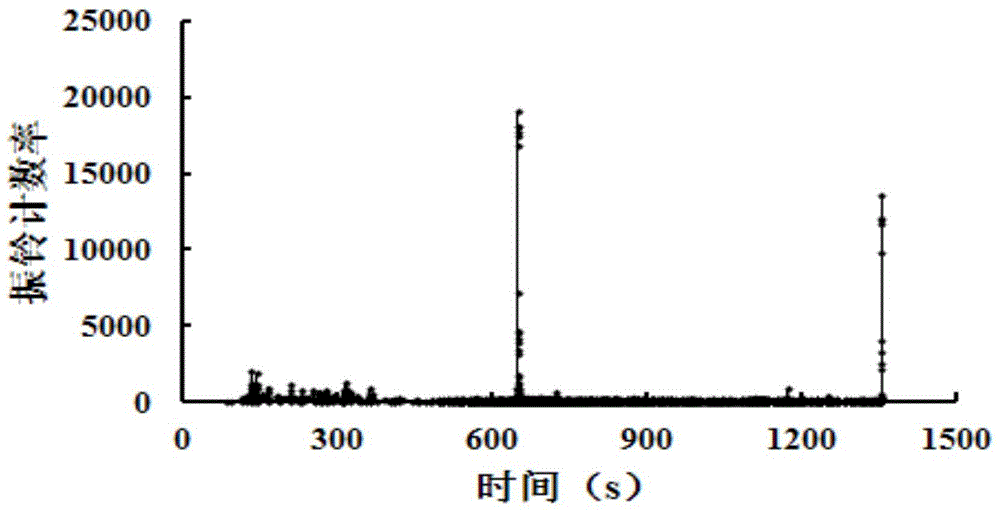

[0035] see Image 6 and Figure 7 As shown, because the load point of the three-point bending test is fixed, the damage formation and development areas are relatively concentrated, the damage mode and damage mechanism are relatively simple, and the obtained acoustic emission signals are relatively simple. It is the use of acoustic emission technology to study material damage and The preferred loading method for fractures. In order to timely monitor the development process of concrete damage and fracture, and compare it with the concrete three-point bending beam fracture test, the acoustic emission test uses a concrete three-point bending beam with prefabricated cracks of the same size as the fracture test. The length of the specimen is 1000 mm, and the width is 120 mm. The height is 200mm; the design strength grades are 25MPa and 60MPa; the diameters of the configuration steel bars are 6mm and 10m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com