Recyclable coarse fracture high velocity seepage testing apparatus

A test device and crack technology, which is applied in the direction of measuring device, permeability/surface area analysis, suspension and porous material analysis, etc., can solve the problems of difficulty in controlling the change of crack opening, less test research, large limitations, etc., to achieve Solve the effect of poor sealing effect, realize the self-circulation of water flow, and avoid the effect of indoor pressurization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing of description, the present invention will be further described.

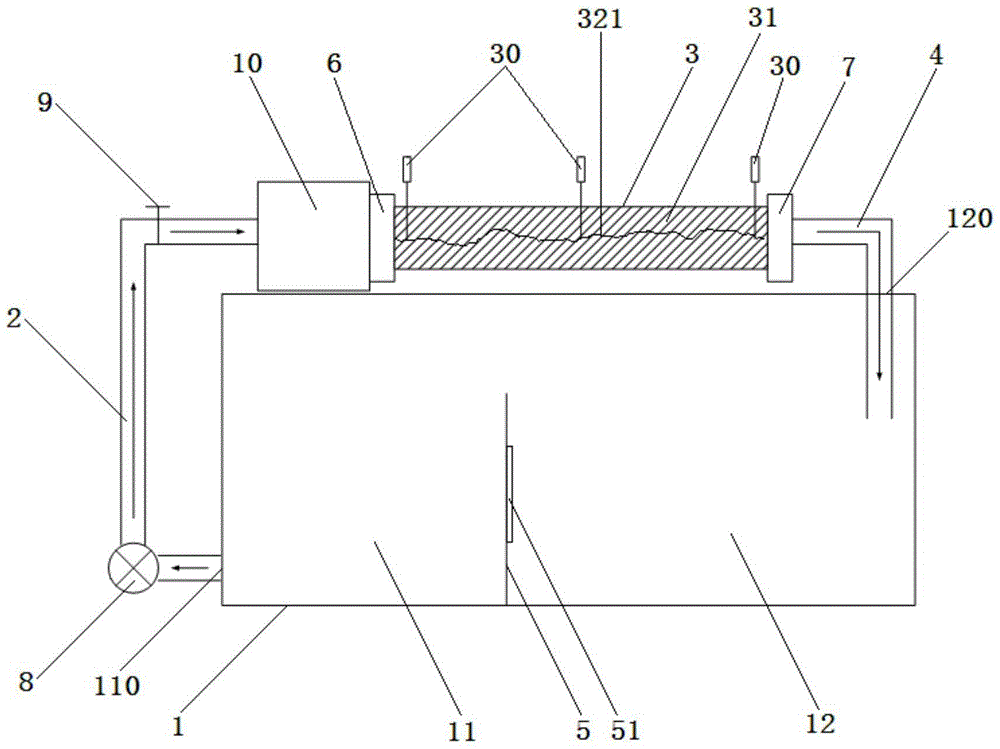

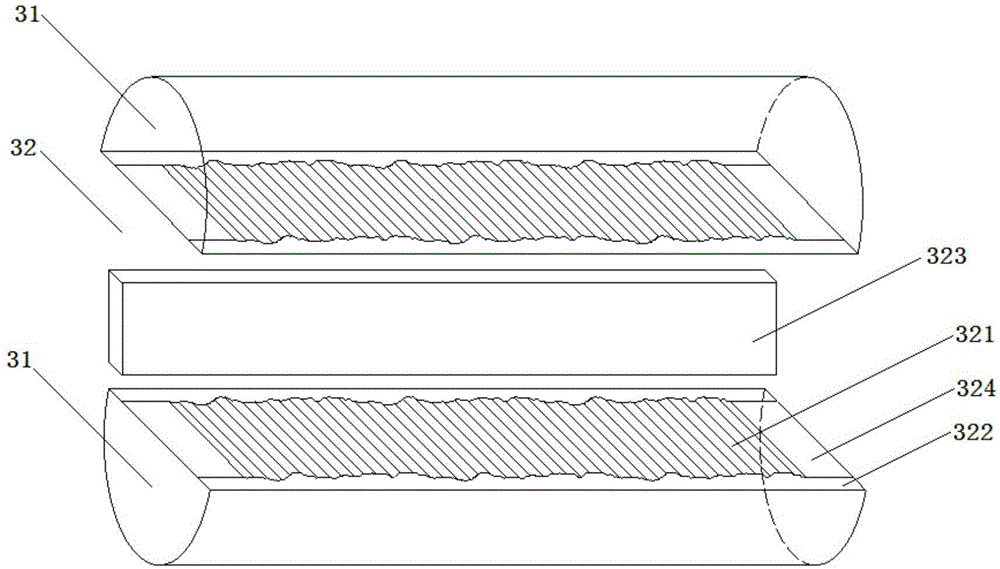

[0031] like figure 1 and figure 2 As shown, a test device for high-speed seepage in circular rough cracks, including a water tank 1, a water supply pipeline 2, a crack test piece 3 and a return water pipeline 4 connected in sequence, the water tank 1 forms a water flow by installing an overflow triangular weir 5 The connected lower water tank 11 and the upper water tank 12 are two water areas.

[0032] The beginning of the water supply pipeline 2 is connected to the water supply port 110 located in the sink 11, the end of the water supply pipeline 2 is connected to the water inlet of the crack test piece 3 through the water inlet cap 6, and the beginning of the return water pipeline 4 is passed through The water outlet cap 7 is connected to the water outlet of the crack test piece 3 , and the end of the return pipe 4 passes through the water return port 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com