Liquid CO2 phase transition multipoint fracturing and permeability increasing method

A cracking and liquid technology, applied in the field of liquid CO2 phase change multi-point cracking and permeability enhancement, which can solve the problems of small cracks, insufficient energy released by single-point cracking, and increased coal seam permeability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing, the patent of the present invention is described further.

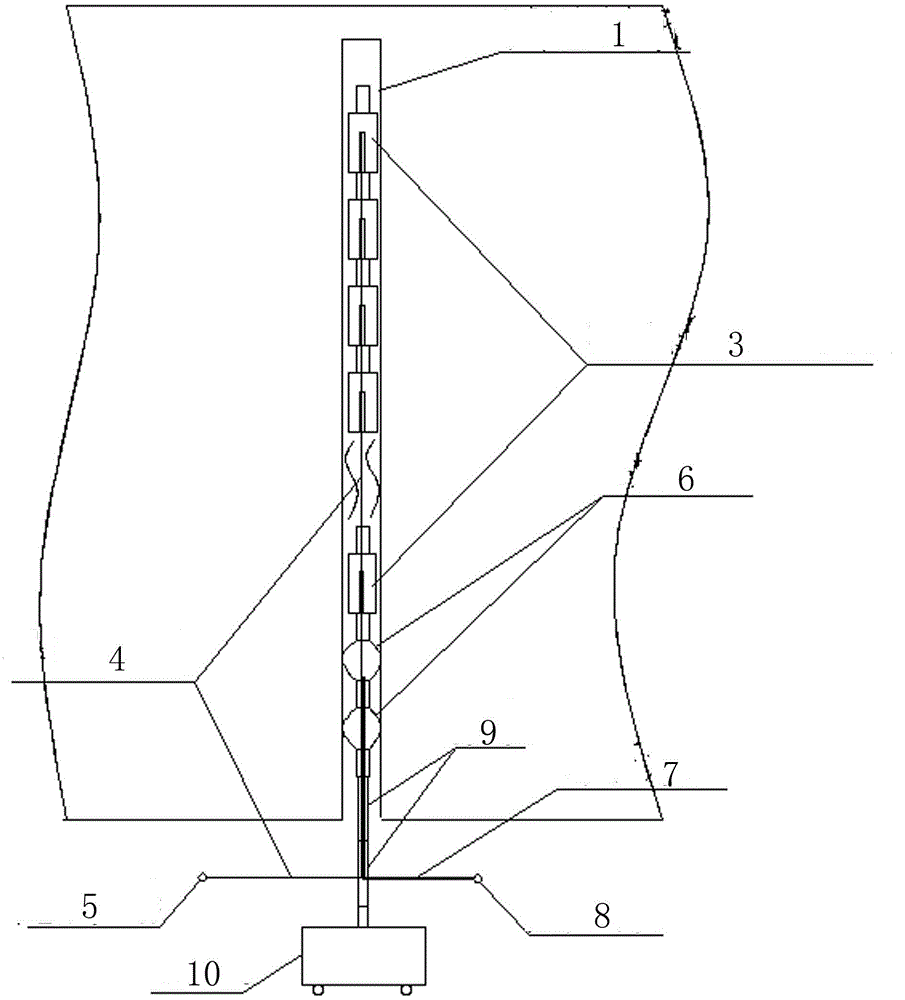

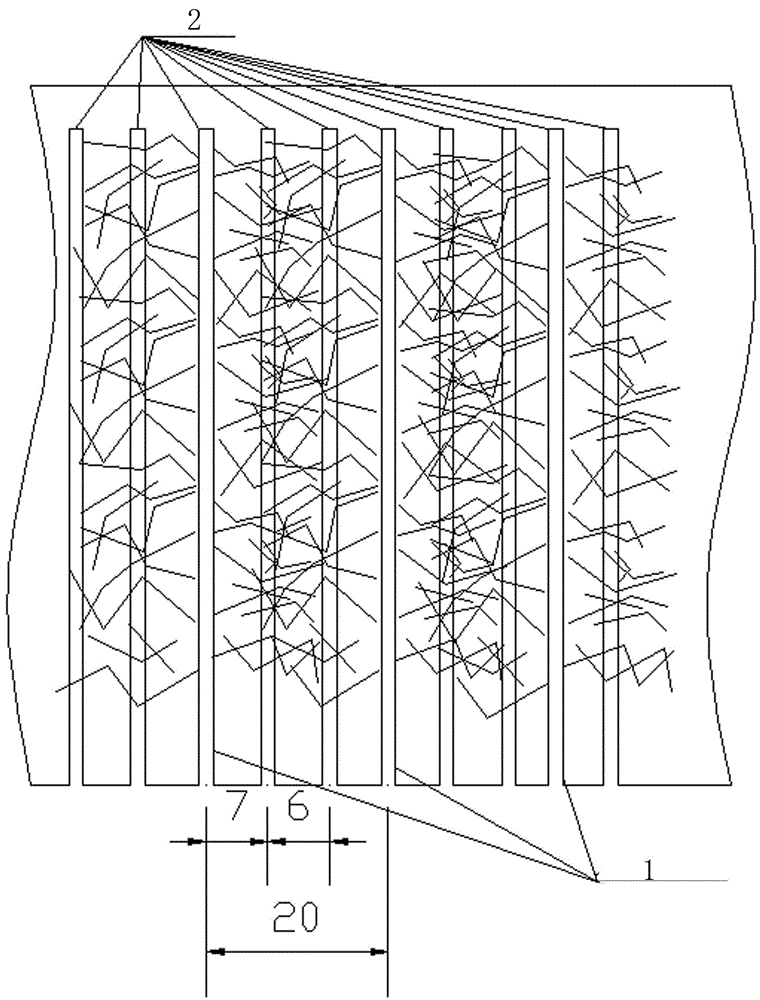

[0019] Liquid CO 2 Phase change multi-point fracturing and anti-reflection method, the arrangement of drilling holes for fracturing test is as follows: figure 1 As shown, there are multiple liquid CO 2 Fracturing tubes (quantity determined by borehole length), and hole sealer, liquid CO 2 The cracking tube is connected through a conductive lead, and the other end is connected to the detonator outside the test drilling. The hole sealing device is connected to the pressure pump through a high-pressure water pipe. After the connection is completed, the push rod is connected to push the cracking tube and the sealing device to the cracking test. In the borehole, the other end of the push rod is connected and fixed with the drilling rig, and then the hole sealing device is filled with water to seal the hole through the pressure pump, and then the liquid CO in the bor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com