Sliding sleeve type fracturing module, device including the module and method of using the device

A sliding sleeve type fracturing technology, which is applied in the direction of wellbore/well valve device, earthwork drilling and production, wellbore/well parts, etc. It can solve the problem that the sliding sleeve cannot be closed and the unlimited number of staged fracturing cannot be realized. , It is impossible to carry out unrestricted series segmentation of the fixed pipe column, etc., so as to achieve the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be further described below in conjunction with accompanying drawing.

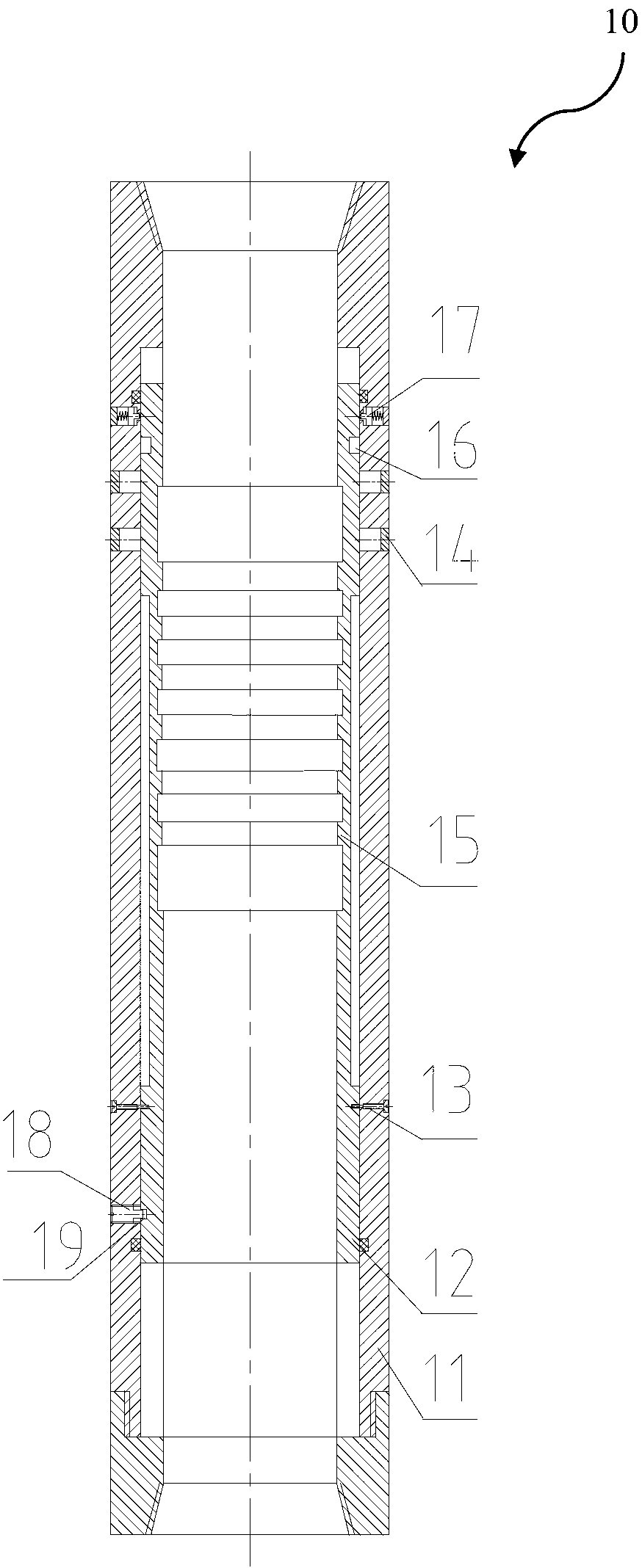

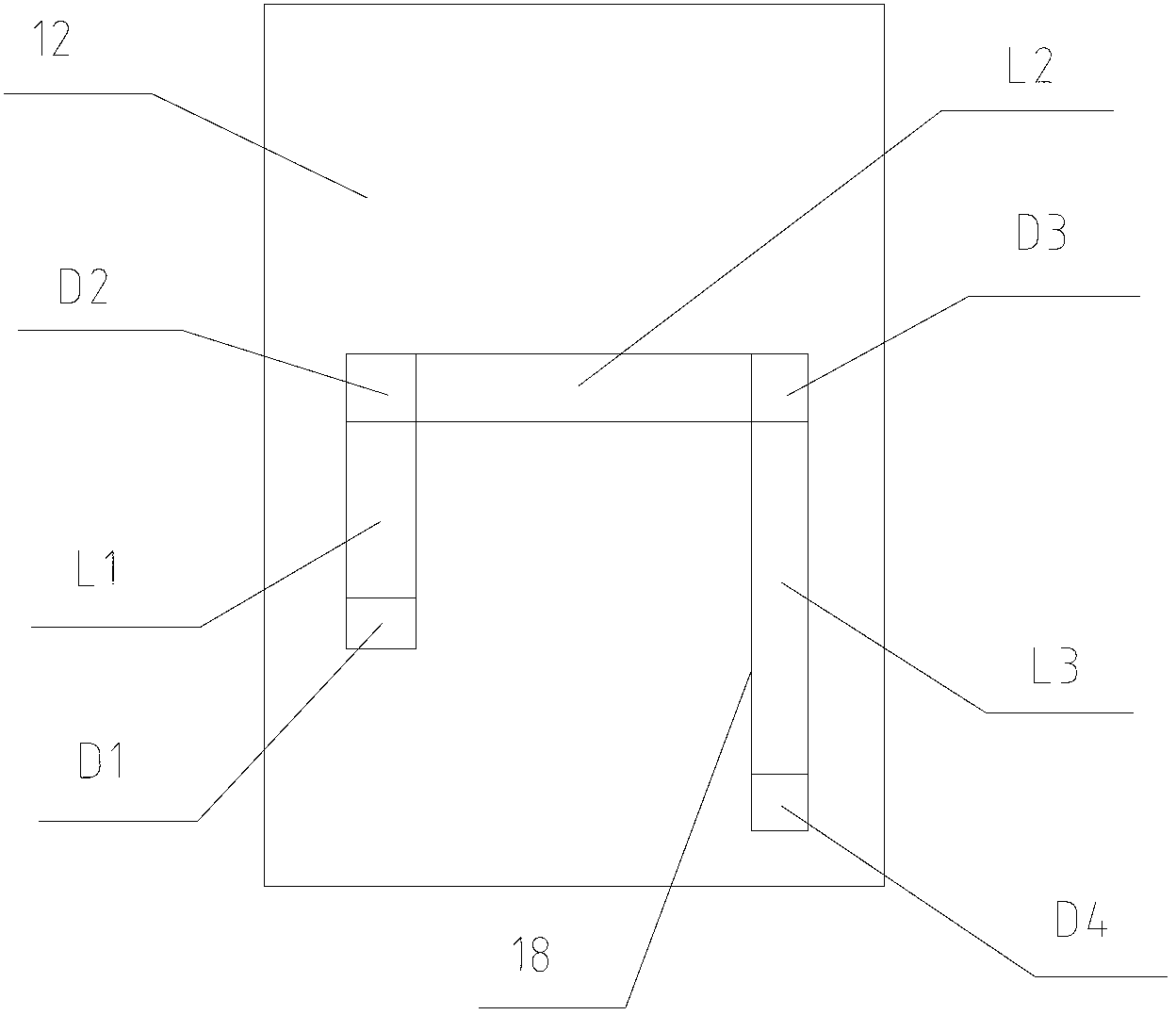

[0056] Figure 1a Shown is a composite sliding sleeve 10 of a sliding sleeve type fracturing assembly according to the present invention, which includes a fixed outer cylinder 11 and an inner cylinder 12 connected to the inner wall of the outer cylinder 11 through shear pins 13 . Wherein, a pump opening valve 14 is provided on the outer cylinder 11 , and a first tooth-shaped member 15 is provided on the inner wall of the inner cylinder 12 . exist Figure 1a In the illustrated embodiment, the first toothed member 15 is formed in one piece with the inner barrel 12 . In one embodiment, a positioning groove 16 and a positioning piece 17 are provided on the mating surfaces of the outer cylinder 11 and the inner cylinder 12 . The positioning groove 16 and the positioning piece 17 are arranged to be in Figure 1a In the shown initial state, they are not engaged with each other, b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com