Combined-type fracturing fluid bio-enzyme gel breaker and application method thereof

A technology of fracturing fluid and gel breaker, which is applied in drilling compositions, chemical instruments and methods, earthwork drilling and mining, etc. It can solve problems such as incomplete gel breaking, reduction of fracturing fluid residue, and short action time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

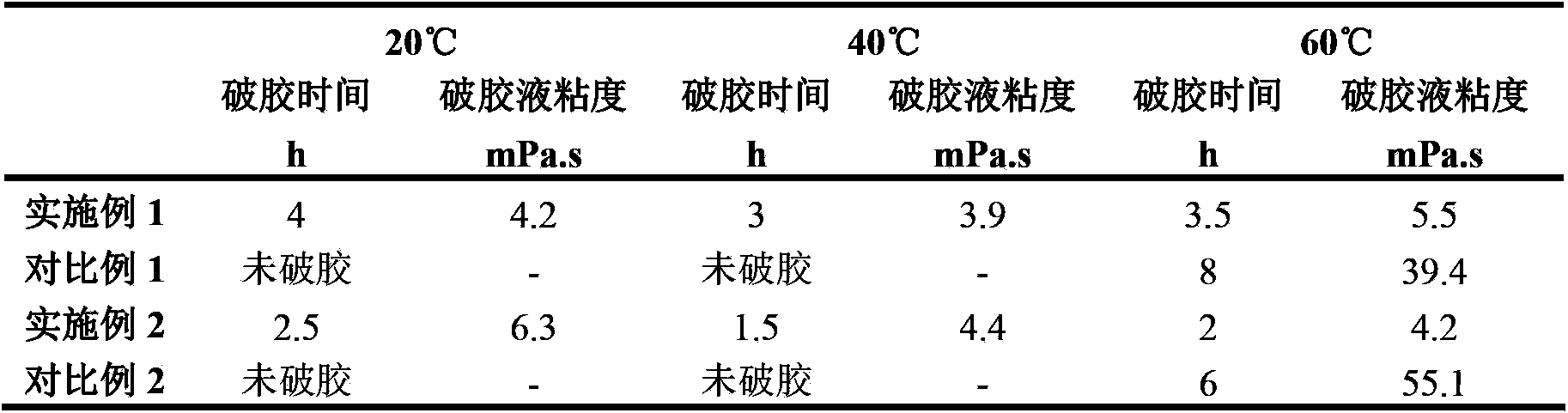

Embodiment 1

[0068] Biological enzyme gel breaker suitable for borax cross-linked hydroxypropyl guar gum system

[0069] Breaker:

[0070] Liquid compound enzyme A: by volume percentage, the liquid compound enzyme A contains 20% alkaline galactomannan enzyme liquid, 0.50% cellulase liquid, 0.50% protease liquid, and 79% water.

[0071] Borax cross-linked hydroxypropyl guar gum HPG fracturing fluid base fluid:

[0072] Prepare borax crosslinked hydroxypropyl guar gum HPG fracturing fluid base fluid according to the following formula: hydroxypropyl guar gum powder HPG0.3wt%, formaldehyde 0.1wt%, citric acid 0.02wt%, sodium bicarbonate 0.05wt%, sodium carbonate 0.05wt%, polyoxyethylene polyoxypropylene pentaethylene hexamine AE10100.1wt%, potassium chloride 2.0wt%, the balance is water, pH8.0, the addition of borax crosslinking agent is 0.05wt%.

[0073] Add the liquid compound enzyme A to the borax cross-linked hydroxypropyl guar gum HPG fracturing liquid base fluid, mix well, and set asi...

Embodiment 2

[0077] Biological enzyme gel breaker for metal cation cross-linked carboxymethyl hydroxypropyl guar gum system

[0078] Breaker:

[0079] Liquid compound enzyme A: by volume, it contains 18% of acidic galactomannan enzyme solution, 1.0% of cellulase solution, 1.0% of protease solution and 80% of water.

[0080] Aluminum ion cross-linked carboxymethyl hydroxypropyl guar gum CMHPG fracturing fluid base fluid:

[0081] Prepare aluminum ion cross-linked carboxymethyl hydroxypropyl guar gum CMHPG fracturing fluid base fluid according to the following formula: carboxymethyl hydroxypropyl guar gum powder CMHPG0.3wt%, formaldehyde 0.1wt%, citric acid 0.02wt%, bicarbonate Sodium 0.05wt%, sodium alkylsulfonate 0.2wt%, polyoxyethylene octylphenol ether 10OP-100.1wt%, the balance is water, pH5.5, crosslinking agent aluminum potassium sulfate 0.5wt%;

[0082] Add the liquid compound enzyme A to the aluminum ion cross-linked carboxymethyl hydroxypropyl guar gum CMHPG fracturing fluid ba...

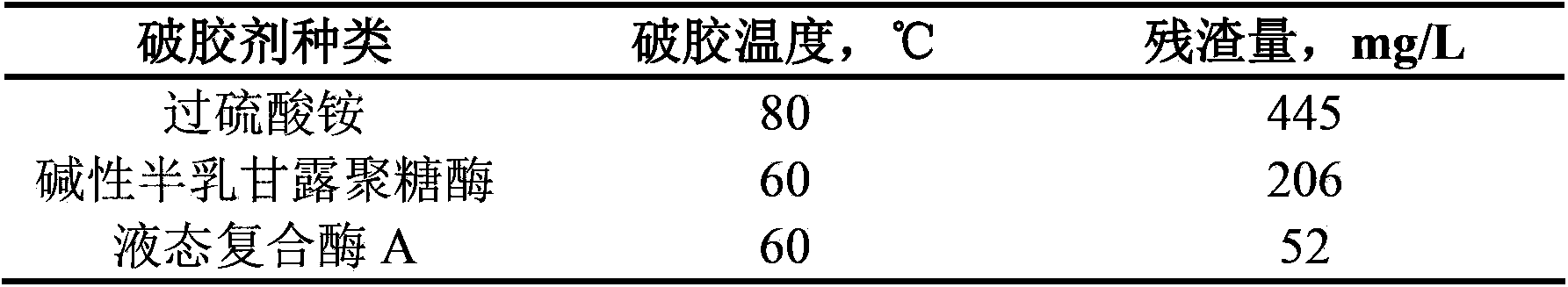

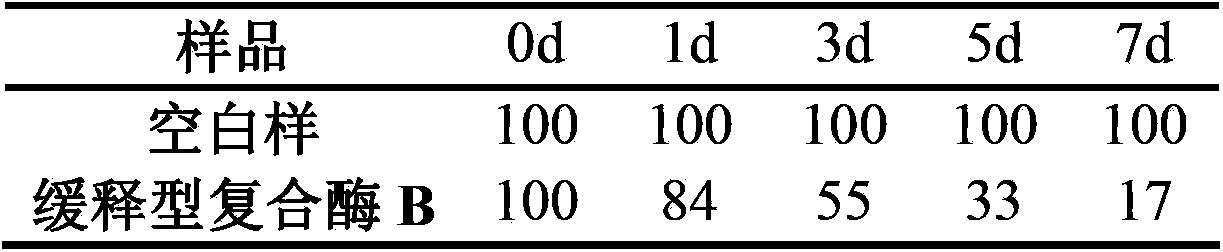

Embodiment 3

[0090] Breaker:

[0091] Liquid compound enzyme A: by volume, it contains 20% alkaline galactomannan enzyme solution, 1% cellulase solution, 1% protease solution, and 78% water.

[0092] Alkaline Galactomannan Enzyme Solution.

[0093] Borax cross-linked hydroxypropyl guar gum HPG fracturing fluid base fluid:

[0094] The borax cross-linked hydroxypropyl guar gum HPG fracturing fluid base fluid was prepared according to the formula in Example 1.

[0095] The alkaline galactomannan enzyme liquid and the liquid compound enzyme A were used as a gel breaker to carry out a gel breaking experiment respectively. The gel breaking test method is "SYT6380-2008 Gel Breaker Performance Test Method for Fracturing", and the experimental temperature Both are 60°C;

[0096] Wherein, the addition is in volume ratio, the addition of the alkaline galactomannan enzyme liquid is 0.002% of the volume of the borax cross-linked hydroxypropyl guar gum HPG fracturing fluid base fluid, and the liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com