Inorganic boron high-temperature delayed fracturing fluid

A fracturing fluid and inorganic boron technology, applied in the field of fracturing fluid, can solve the problems of large damage to the supporting fracture reservoir, large amount of gel breaker, low gel breaking efficiency, etc., to improve performance and utilization, reduce damage, The effect of improving the breaking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

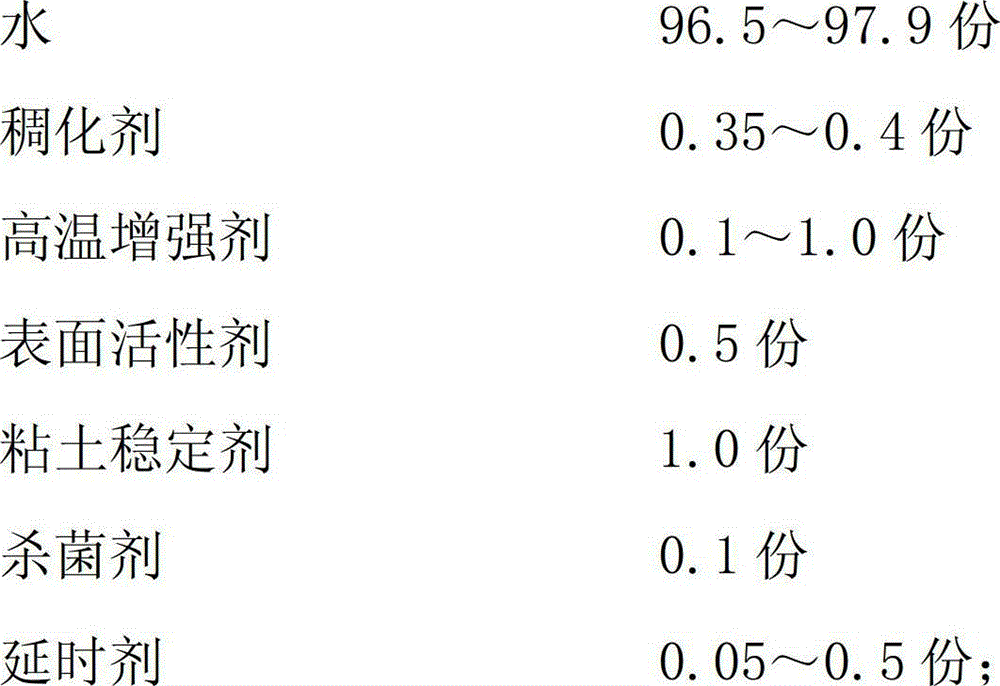

Method used

Image

Examples

Embodiment 1

[0027] 30m on site 3 Add 2895Kg of water into the container, and slowly add 12.0Kg of hydroxypropyl guar gum while stirring with a pump or a stirrer, and then add 30.0Kg of potassium chloride, 15.0Kg of sodium lauryl sulfate, and 30.0Kg of TA -2 high temperature enhancer, 3.0Kg formaldehyde, 15.0KgYS-1 delay agent, continue to circulate or stir for 30 minutes, so that the liquid is fully mixed to form solution A1. JWL-1 crosslinker is solution A2. During fracturing construction, while pumping solution A1, solution A2 is mixed with solution A1 at the ratio of solution A1:solution A2=100 liters:0.7 liters to form a fracturing fluid.

[0028] The above fracturing fluids are recommended to be used in oil and gas wells where the well temperature is lower than 120°C.

Embodiment 2

[0030] 30m on site 3 Add 2910Kg of water to the container, and slowly add 10.5Kg of hydroxypropyl guar gum while stirring with a pump or a stirrer, and then add 30Kg of ammonium chloride, 15Kg of sodium lauryl sulfate, and 30.0Kg of TA-2 Heat-resistant enhancer, 3.0Kg formaldehyde, 1.5Kg YS-1 delay agent, continue to circulate or stir for 30 minutes, so that the liquid is fully mixed to form solution A1. JWL-1 crosslinker is solution A2. During fracturing construction, while pumping solution A1, mix solution A2 with solution A1 at a volume ratio of solution A1: solution A2 = 100 liters: 1.0 liters to form a fracturing fluid.

[0031] The above fracturing fluids are recommended to be used in oil and gas wells where the well temperature is lower than 110°C.

Embodiment 3

[0033] 30m on site 3 Add 2922Kg of water to the container, and slowly add 12.0Kg of hydroxypropyl guar gum while stirring with a pump or a stirrer, and then add 30.0Kg of potassium chloride, 15.0Kg of sodium lauryl sulfate, and 3.0Kg of TA -2 high temperature enhancer, 3.0Kg formaldehyde, 15.0KgYS-1 delay agent, continue to circulate or stir for 30 minutes, so that the liquid is fully mixed to form solution A1. JWL-1 crosslinker is solution A2. During fracturing construction, while pumping solution A1, mix solution A2 with solution A1 at a ratio of solution A1:solution A2=100 liters:0.8 liters to form a fracturing fluid.

[0034] The above fracturing fluids are recommended to be used in oil and gas wells where the well temperature is lower than 100°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com