Microemulsion-type fracture acidizing cleanup additive, and preparation method and application thereof

A technology of fracturing acidification and drainage aids, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of insurmountable reservoir damage and complicated preparation, and achieve the restoration of reservoir permeability and simple preparation process , The effect of stable product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A microemulsion type fracturing acidification drainage aid, the components and mass parts are as follows:

[0029] Sodium dodecylbenzene sulfonate: 5 parts; n-butanol: 4 parts; kerosene: 41 parts; water: 42 parts; sodium chloride: 8 parts.

[0030] Weigh sodium dodecylbenzene sulfonate, n-butanol, kerosene, water, and sodium chloride according to the above-mentioned mass parts and mix and stir them evenly, and then let stand for 1~3h to obtain microemulsion type fracturing acidification aid. Agent.

[0031] The microemulsion type fracturing acidification drainage aid is added according to the ratio of 0.7% of the mass of the fracturing acidification fluid, and the mixture is uniformly mixed and pumped into the bottom layer.

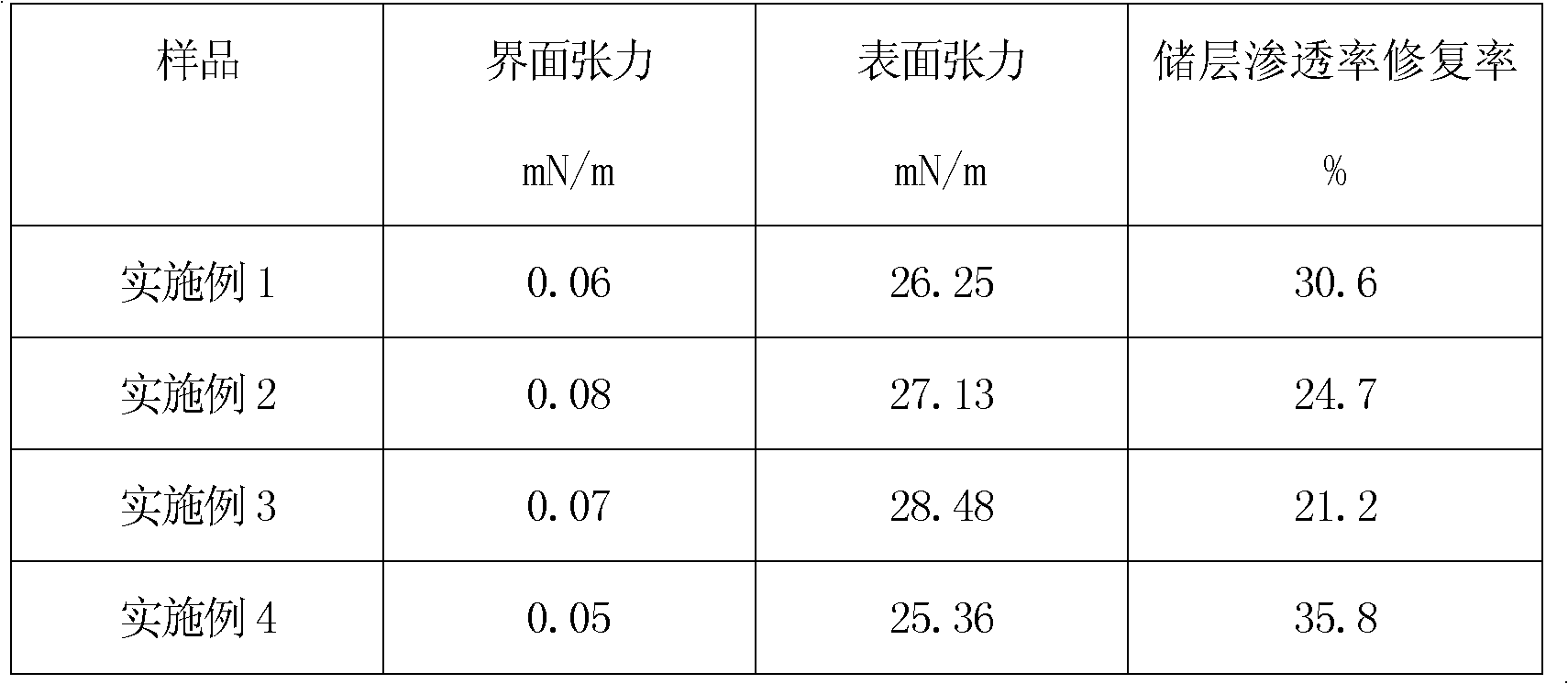

[0032] After testing, the density, interfacial tension, surface tension, reservoir permeability repair rate and other test data of the microemulsion fracturing acidification drainage aid are shown in Table 1.

Embodiment 2

[0034] The microemulsion type fracturing acidification drainage aid as described in Example 1, except that the components and mass parts are as follows:

[0035] Sodium fatty acid methyl sulfonate: 6 parts; isobutanol: 5 parts; kerosene: 42 parts; water: 42 parts; sodium chloride: 5 parts.

[0036] The microemulsion type fracturing acidification drainage aid is added according to the ratio of 0.5% of the mass of the fracturing acidification fluid, and the mixture is uniformly mixed and pumped into the bottom layer.

[0037] After testing, the test data of interfacial tension, surface tension, and reservoir permeability repair rate of the microemulsion fracturing acidification drainage aid are shown in Table 1.

Embodiment 3

[0039] The microemulsion type fracturing acidification drainage aid as described in Example 1, except that the components and mass parts are as follows:

[0040] Sodium lauryl sulfate: 7 parts; n-pentanol: 6 parts; white oil: 40 parts; water: 40 parts; potassium chloride: 7 parts.

[0041] Add the microemulsion type fracturing acidification drainage aid according to the proportion of 0.4% of the mass of the fracturing acidification fluid, mix it evenly and pump it into the bottom layer.

[0042] After testing, the test data of interfacial tension, surface tension, and reservoir permeability repair rate of the microemulsion fracturing acidification drainage aid are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com