Flange type fracturing combination manifold device with damping device

A shock-absorbing device, flange-type technology, applied in the direction of mining fluid, wellbore/well components, earthwork drilling and production, etc., can solve the problems of increased erosion, increased friction, and easy failure of high and low pressure pipelines, etc., to achieve convenient lifting , to reduce the effect of impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

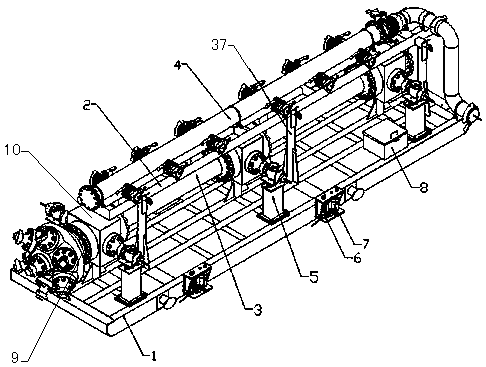

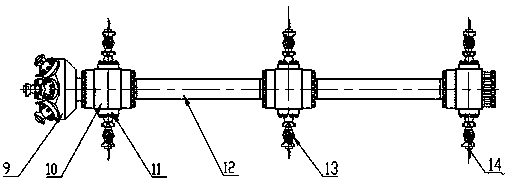

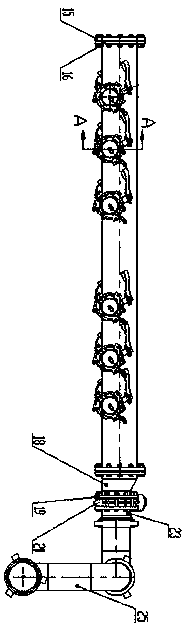

[0020] figure 1 Middle: The flanged fracturing combined manifold with shock absorbing device includes: high pressure manifold skid 1, low pressure manifold skid 2, high pressure manifold 3, low pressure manifold 4, shock absorbing device 5, hydraulic jack mounting bracket 6, Hydraulic jack 7, tool box 8, in which the high-pressure manifold 3 is dragged over the pallet and fixed on the high-pressure manifold skid 1, and the high-pressure manifold skid 1 is equipped with a shock absorbing device 5 which can fully absorb the vibration from the fracturing vehicle and reduce the impact of vibration on the high-pressure The high pressure components in the manifold 3, especially the impact of the non-type plug valve 13, the low pressure manifold 4 is fixed on the low pressure manifold skid 2 through a clamp, and the high pressure manifold skid 1 and the low pressure manifold ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com