Fractured reservoir horizontal well injection-production asynchronous exploitation method

A mining method and technology for horizontal wells, which are applied in the fields of production of fluids, earth-moving drilling, wellbore/well components, etc., can solve the problems of low final recovery rate, low formation energy, rapid production decline, etc. Water content, the effect of replenishing formation energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

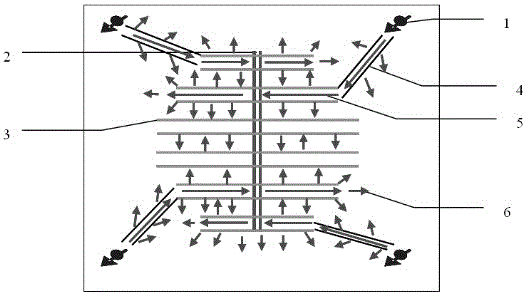

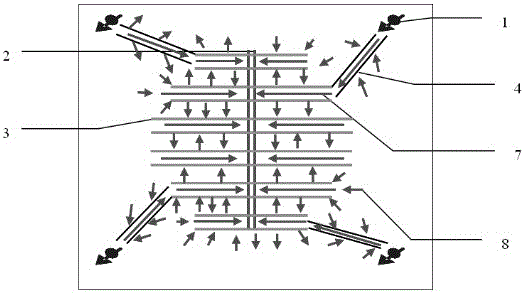

[0033] In order to overcome the problems of rapid formation energy reduction, rapid production decline, and low final recovery in the existing method, the present invention provides figure 1 , figure 2 The asynchronous production method for horizontal well injection and production in fractured oil reservoirs is shown. The present invention utilizes the role of injected water in the penetration and replacement of the crude oil in the reservoir rock with the fracture as the medium. The stimulation mechanism is mainly through periodic Water injection huffs and puffs, to give full play to the capillary reverse imbibition of the matrix, replace the crude oil in the matrix rock block into the fractures for exploitation, so as to realize the effective development of fractured low-permeability reservoirs that are difficult to produce by conventional water injection development.

[0034] An asynchronous injection-production method for horizontal wells in fractured reservoirs, the specific ...

Embodiment 2

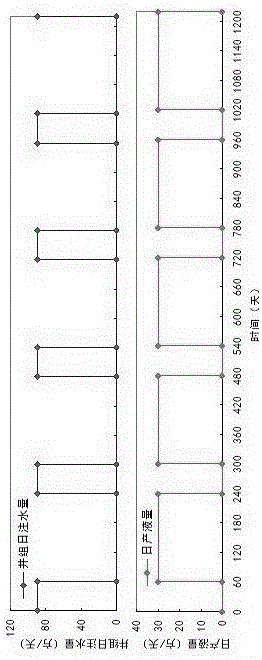

[0048] Based on the foregoing embodiment, in this embodiment, each water injection period is 60 days, and the oil production period is 180 days.

[0049] In the production stage of horizontal production wells, the production cycle is about 180 days, and the output of a single well is about 30 cubic meters. At the end of the production period, the formation pressure is slightly higher than the saturation pressure, and the cycle cumulative fluid production is about 5500 cubic meters. The cycle injection and production are basically balanced.

[0050] In the step 2), in the water injection process, the injected water 6 enters the oil-bearing pores of the matrix rock block around the horizontal well 2 along the open natural fractures and horizontal well 2 fractures under the dual effects of water injection pressure and capillary pressure .

[0051] During the water injection process, the formation pressure is gradually restored, the pressure is maintained at 90-100% of the original forma...

Embodiment 3

[0056] Based on the foregoing embodiment, in this embodiment, the horizontal oil production well in step 2) is shut in, and the water injection well 1 is injected with 90 cubic meters of water. During the water injection process, the formation pressure gradually recovered, the pressure remained at 95% of the original formation pressure, and the oil and water in the horizontal well 2 area redistributed. Repeat steps 2) and 3) of the water injection and oil extraction process, and the entire cycle is selected as 9 cycles.

[0057] In the first cycle of asynchronous injection-production, the daily production and cumulative oil production of a single well is the highest, and the water cut is the lowest. With the increase of water cut, the decrease of remaining oil, the gradual decline in production, and the gradual increase of water cut, the best asynchronous injection-production cycle is 9 cycle. During the asynchronous injection-production process, the opening and shut-in processe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average permeability | aaaaa | aaaaa |

| Permeability | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com