Cool sweat-absorbent quick-drying knitted fabric and application thereof

A knitted fabric, cool technology, applied in knitting, weft knitting, warp knitting and other directions, can solve problems such as stuffy heat and wearer discomfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

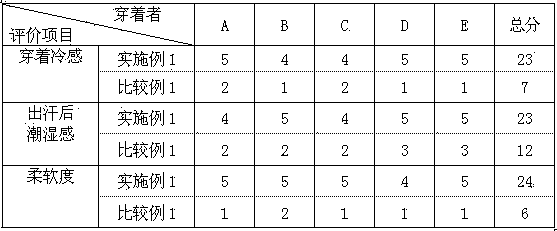

Examples

Embodiment 1

[0043] Using 110dtex-48f-PET composite fiber (8-lobe ordinary PET weight ratio is 75%, easily soluble PET weight ratio is 25%) and 84dtex-144f-PET false-twisted yarn are woven on a 28G double-sided knitting machine under conventional conditions. The double-sided tuck structure is used, so that the PET false twist yarn is exposed on the surface layer, and the composite fiber is exposed on the inner layer. After scouring to remove oil and intermediate setting, caustic soda is used to reduce the weight, so that the easily soluble PET is completely dissolved to form an 8-leaf yarn. Then it is dyed according to ordinary PET knitted fabric, processed by water absorption, and after finishing and shaping, the weight is about 140g / m 2 of knitted fabrics.

[0044] Scouring conditions: 0.2% surfactant solution was treated at 85°C for 20 minutes, and the intermediate setting was set at 190°C for about 2 minutes.

[0045] Use 0.1% maleic acid solution to treat at 120°C for 30 minutes, dr...

Embodiment 2

[0048] Except that the ordinary PET in the composite yarn has a 10-leaf shape, the others are the same as in Example 1.

[0049]The inner layer yarn in the obtained knitted fabric is 100% 10-lobe PET yarn, accounting for 47% of the whole fabric; its monofilament fineness is 2.9 times that of the outer layer yarn, and the monofilament specific surface area is that of the same denier PET yarn. 6 times, the surface-to-surface diffusion area ratio is 3.6:1; the contact coldness value is 1.26 W / cm2.

Embodiment 3

[0051] Using 84dtex-48f-PET composite fiber (6-leaf type ordinary PET weight ratio 75%, easily soluble PET weight ratio 25%) and 84dtex-144f-PET false twisted yarn are woven on a 28G double-sided knitting machine, and the rest are the same as in Example 1 . The obtained gram weight is about 130g / m 2 of knitted fabrics.

[0052] The inner layer yarn in the obtained knitted fabric is 100% 6-lobe PET yarn, accounting for 40% of the whole fabric; its monofilament fineness is 2.3 times that of the outer layer yarn, and the monofilament specific surface area is that of the same denier PET yarn. 4 times, the surface-to-interior diffusion area ratio is 3.3:1; the contact coldness value is 1.24 W / cm2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gram weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com