Aluminum alloy surface wear-resisting coating and preparation method and application thereof

A technology of aluminum alloy surface and wear-resistant coating, which is applied in the direction of metal material coating process, coating, superimposed layer plating, etc. Problems such as failure to improve the bonding force of the matrix to achieve the effect of improving performance, excellent anti-friction and wear performance, and weakening the difference in mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] Another aspect of the embodiments of the present invention also provides a method for preparing a wear-resistant coating on an aluminum alloy surface, which includes:

[0039] Magnetron sputtering technology is used to deposit and form a titanium primer layer on the surface of the substrate under a protective atmosphere;

[0040] Using plasma-enhanced chemical vapor deposition technology, a mixed gas of acetylene and hexamethyldisiloxane is used as the working gas of the ion source of the anode layer, and a composite gradient transition layer is deposited on the surface of the titanium primer layer; wherein, the composite gradient The transition layer includes more than three silicon-oxygen-doped amorphous carbon transition layers with different silicon-oxygen contents formed in the thickness direction of the coating;

[0041] And, using plasma-enhanced chemical vapor deposition technology, acetylene is used as the working gas of the ion source of the anode layer, and a...

Embodiment 1

[0062] (1) Use plasma to etch and clean the surface of aluminum alloy (or silicon wafer, for microscopic morphology characterization) for 10 minutes to remove surface impurities and increase interface bonding strength to obtain a pretreated aluminum alloy surface, wherein the ion source of the anode layer The working gas is argon, the chamber pressure is 0.40Pa, the ion source constant current is 1A, the voltage is 1100V, and the substrate negative bias is -300V;

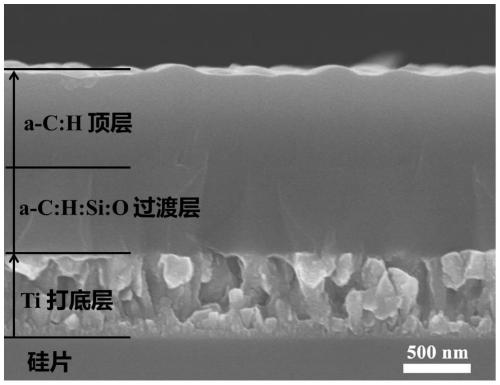

[0063] (2) Using DC magnetron sputtering technology, prepare a layer of Ti with a thickness of 800nm on the surface of aluminum alloy (or silicon wafer), wherein the cavity pressure is 0.35Pa, and the magnetron sputtering constant current is 3A The emission voltage is 460V, and the deposition negative bias is -100V;

[0064] (3) Using plasma-enhanced chemical vapor deposition technology, using acetylene and hexamethyldisiloxane as the working gas of the ion source of the anode layer, a composite gradient transitio...

Embodiment 2

[0069] (1) Use plasma to etch and clean the aluminum alloy surface for 10 minutes to remove surface impurities and increase the interface bonding strength to obtain a pretreated aluminum alloy surface, wherein the working gas of the ion source of the anode layer is argon, and the chamber pressure is 0.35Pa , in the ion source constant current mode of 1A, the voltage is 1150V, and the base negative bias is -200V;

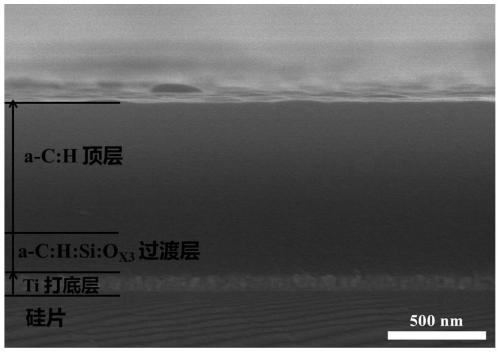

[0070] (2) Using DC magnetron sputtering technology, prepare a layer of Ti with a thickness of 500nm on the surface of the aluminum alloy, where the chamber pressure is 0.38Pa, the magnetron sputtering constant current is 3A, the sputtering voltage is 450V, The deposition negative bias is -150V;

[0071] (3) Using plasma-enhanced chemical vapor deposition technology, using acetylene and hexamethyldisiloxane as the working gas of the ion source of the anode layer, a composite gradient transition layer with a total thickness of 200nm was prepared on the Ti primer layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com