Hot-rolled complex phase steel plate with good broaching performance and production method thereof

A production method and performance technology, applied in the field of ferrite/bainite multiphase steel and its production, can solve the problems of low strength level, and achieve the effect of reducing the difference in mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

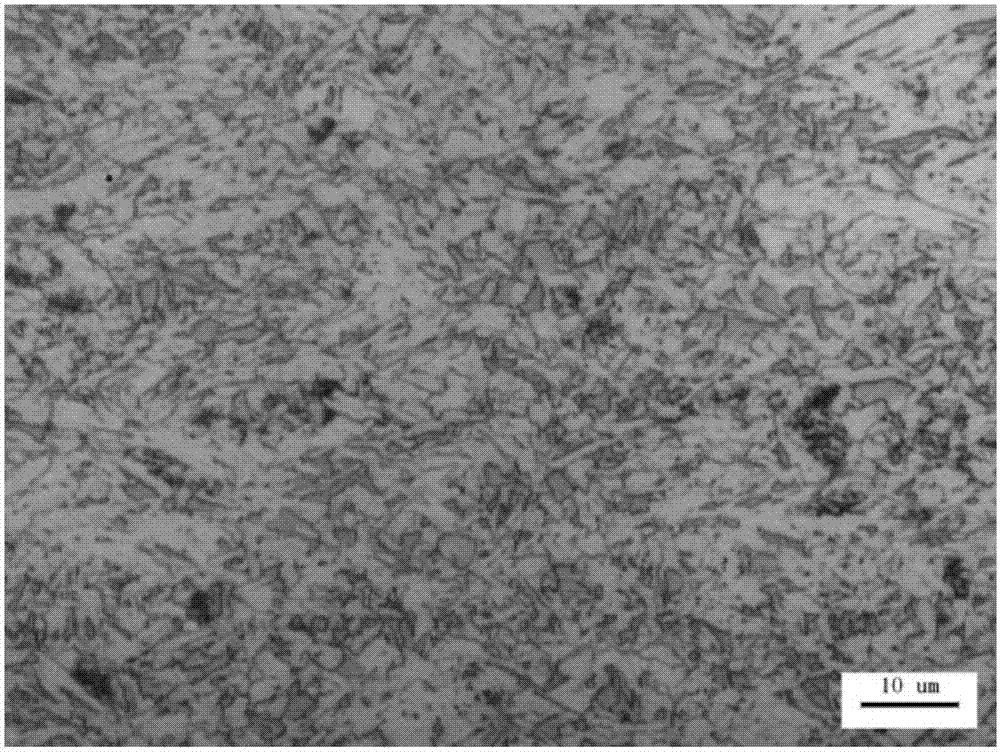

Image

Examples

Embodiment Construction

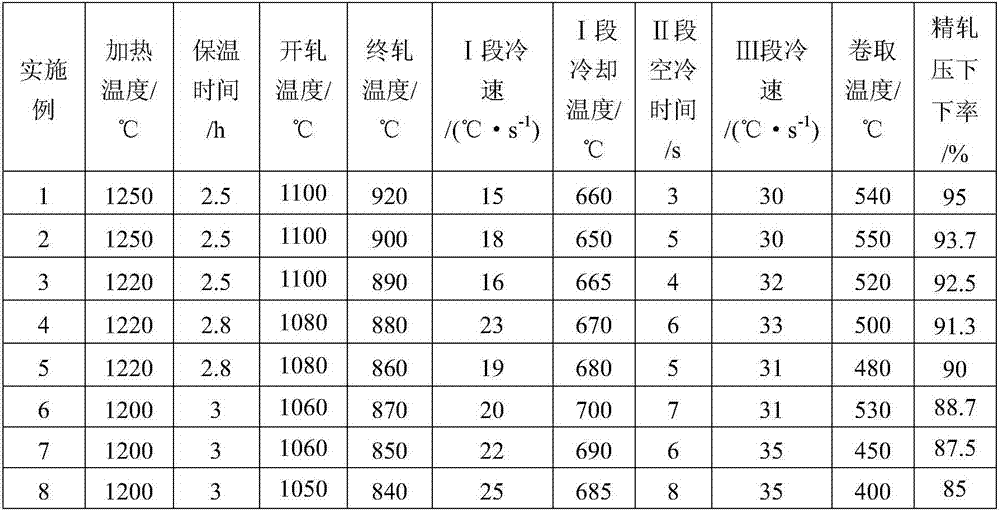

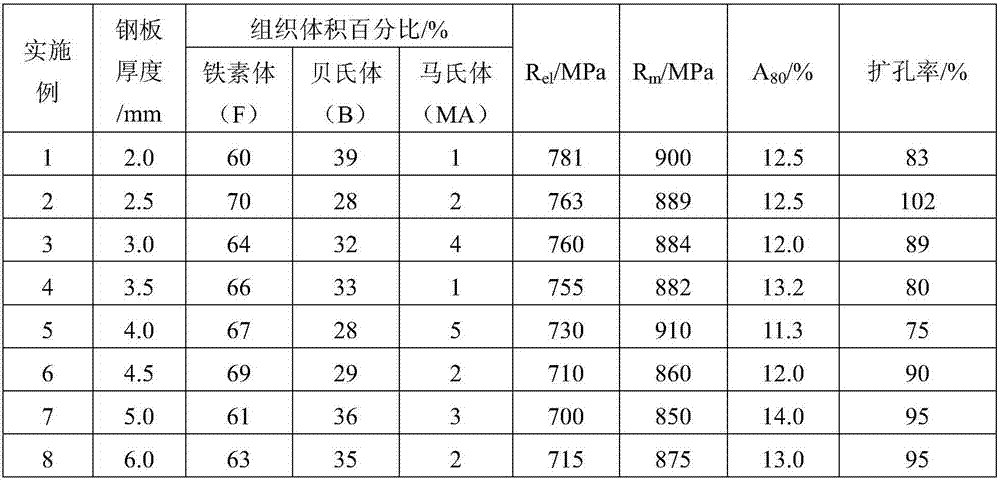

[0031] The technical problems involved in the present invention are solved by the following technical solutions: a hot-rolled multiphase steel plate with good hole expansion performance and its manufacturing method, the mass percentage of its chemical composition is: C: 0.03%~0.12%, Si: 0.1%~ 0.7%, Mn: 1.2%~2.2%, P≤0.012%, S≤0.005%, Cr: 0.25%~0.70%, V: 0.05%~0.25%, Ti: 0.06%~0.16%, Als: 0.015%~ 0.060%, the rest is Fe and unavoidable impurities. The continuous casting slab with the above composition is heated to 1170-1270°C, and the slab is rolled in multiple passes on the rolling mill. ℃, cooling after rolling is divided into three sections: Section I: Cooling rate: 15~25℃ / s, temperature: 650~700℃; Section II: air cooling: 3~8s; Section III: not less than 30℃ / s The cooling speed is cooled to the coiling temperature of 400-550°C, and then air-cooled to room temperature.

[0032] The following examples are used to specifically illustrate the contents of the present invention, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com