Alumina carrier and its preparation method and hydrogenation catalyst and its preparation method

A technology of alumina carrier and hydrogenation catalyst, which is applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, catalyst carrier, etc., which can solve the problem of difficulty in preparing alumina carrier and limited pore expansion and other issues to achieve the effect of improving the ability to remove and accommodate metals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

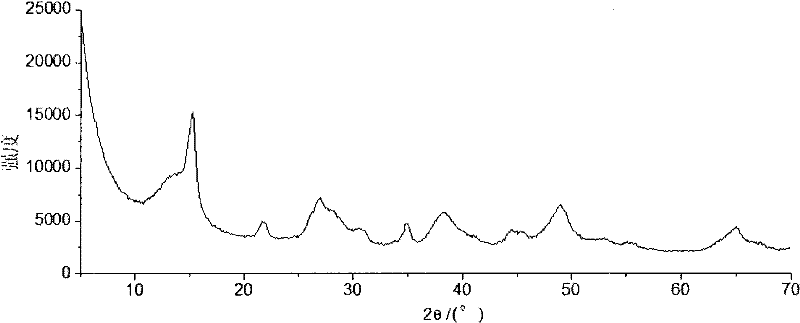

Image

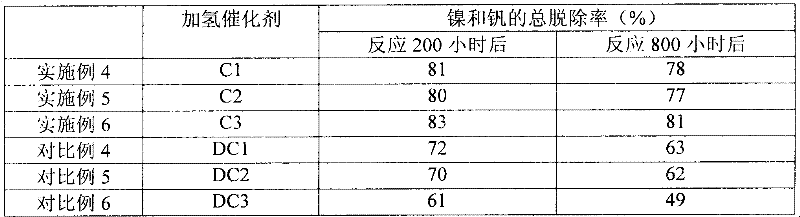

Examples

preparation example Construction

[0018] The present invention also provides a method for preparing an alumina carrier. The method comprises forming, drying and roasting a mixture containing hydrated alumina and water, wherein the hydrated alumina contains pseudo-boehmite and basic aluminum carbonate Ammonium.

[0019] In the preparation method of the alumina carrier provided by the present invention, since the hydrated alumina contains basic ammonium aluminum carbonate, on the one hand basic ammonium aluminum carbonate can act as a pore expander, and on the other hand, basic ammonium aluminum carbonate The ammonium aluminum carbonate can play the role of framework support, so that an alumina support with a large pore diameter can be made according to the preparation method of the alumina support. In order to make the alumina carrier made of the hydrated alumina have better thermal stability and mechanical strength, preferably, in the hydrated alumina, the content of the pseudo-boehmite is 85-99 by weight %, the...

Embodiment 1

[0050] This example is used to illustrate the alumina carrier provided by the present invention and its preparation method.

[0051] (1) Preparation of hydrated alumina

[0052] Weigh 483 grams of aluminum chloride (purchased from Beijing Chemical Plant), add to deionized water and dissolve to make a solution a1 with a concentration of 1 mol / L; weigh 210 grams of sodium metaaluminate (purchased from Tianjin Tianjin Branch Fine Chemical Research Institute), add it to deionized water and dissolve it to make a solution b1 with a concentration of 3.0 mol / L; weigh 230 g of ammonium carbonate (purchased from Beijing Chemical Reagent Company), add it to deionized water and dissolve it to prepare Into a solution c1 with a concentration of 0.5 mol / liter. The solution a1 and the solution b1 are simultaneously added to a 10 liter gel forming tank in a co-current manner for reaction, and the pH value in the gel forming tank is maintained at 8.5 by controlling the flow rate of the solution a1 ...

Embodiment 2

[0068] This example is used to illustrate the alumina carrier provided by the present invention and its preparation method.

[0069] (1) Preparation of hydrated alumina

[0070] Weigh 666 grams of aluminum sulfate (purchased from Beijing Chemical Plant), add it to deionized water and dissolve to make a solution a2 with a concentration of 0.5 mol / L; weigh 210 grams of sodium metaaluminate (purchased from Tianjin Jinke Fine Chemical Research Institute), add it to deionized water and dissolve it to make a solution b2 with a concentration of 2.0 mol / L; weigh 370 grams of ammonium bicarbonate (purchased from Beijing Chemical Reagent Company), add it to deionized water and dissolve it to prepare Into a solution c2 with a concentration of 1.0 mol / liter. The solution a2 and solution b2 are simultaneously added to a 10-liter gel forming tank in a co-current manner for reaction, and the pH value in the gel forming tank is maintained at 6.0 by controlling the flow rate of solution a2 and sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore diameter | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com