1180 MPa-grade precipitation strengthened hot rolled ultra-high-strength steel and manufacturing method thereof

An ultra-high-strength steel and precipitation strengthening technology, applied in the field of hot-rolled high-strength steel, can solve the problems of high strength and high hole expandability, poor hole expandability, and difficulty in achieving ultra-high strength.

Active Publication Date: 2016-07-06

BAOSHAN IRON & STEEL CO LTD

View PDF5 Cites 16 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Single ferrite or bainite structure has high hole expansion performance, but its strength is relatively low, and it is difficult to achieve ultra-high strength; while ferrite and martensite structure have low yield ratio and Higher strength, but due to the large difference in properties between ferrite and martensite, its hole expandability is the worst among high-strength steels of the same strength level and different structure types

In other words, it is often difficult to have both high strength and high hole expandability

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0053] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Login to View More

Abstract

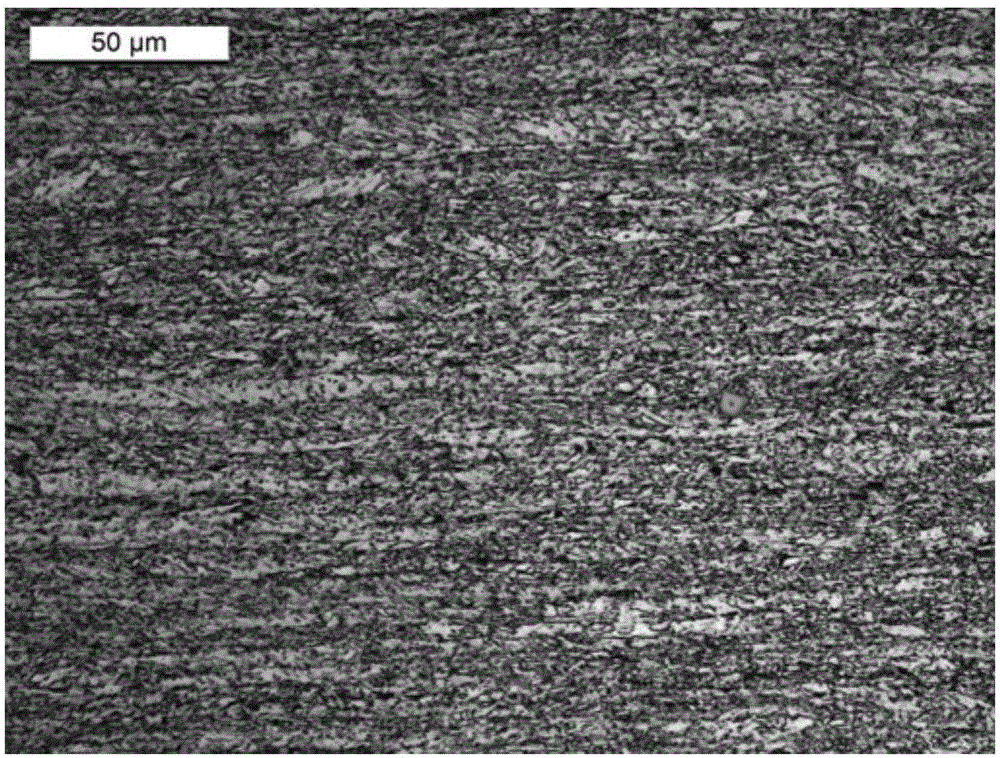

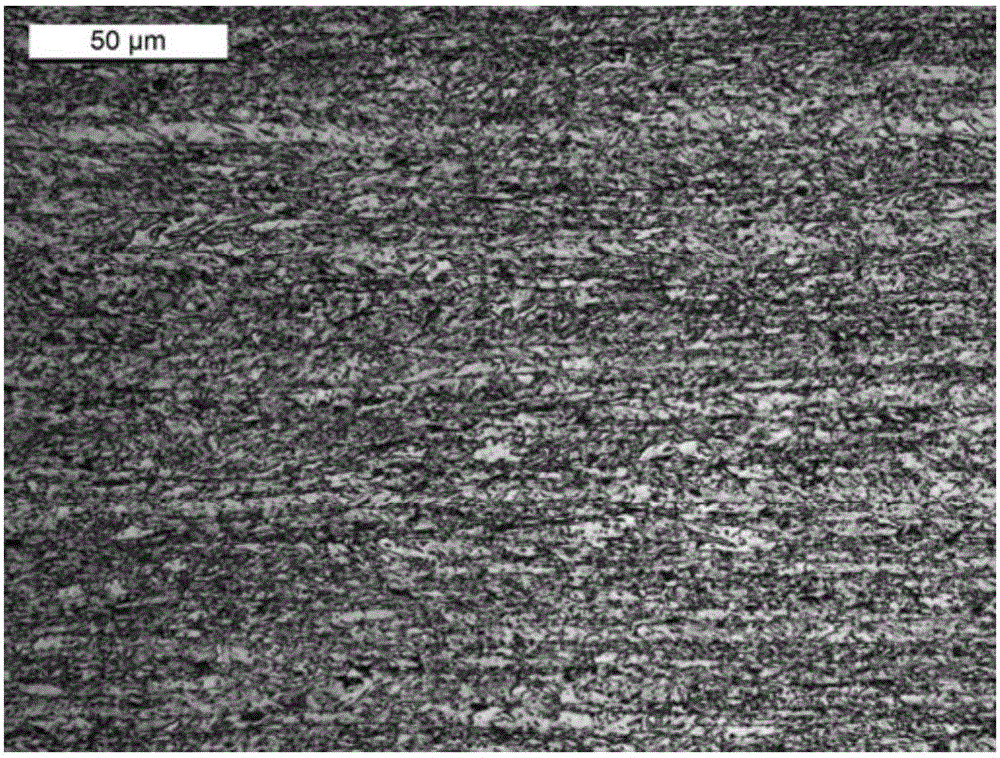

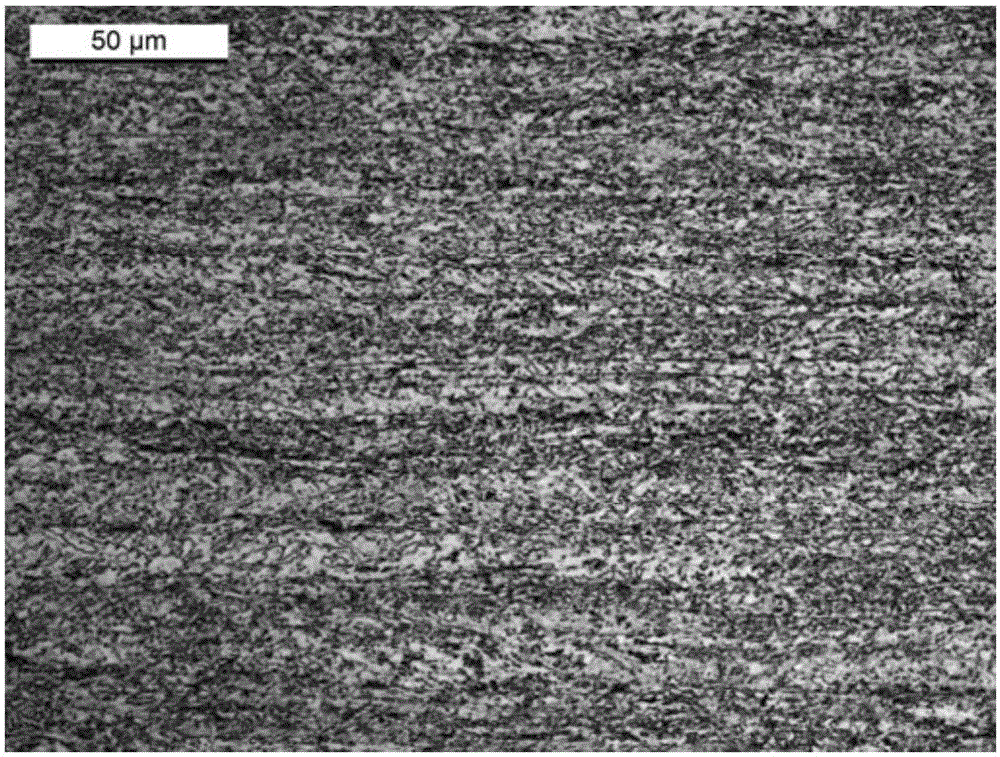

Provided are 1180 MPa-grade precipitation strengthened hot rolled ultra-high-strength steel and a manufacturing method thereof. The steel is prepared from, by weight, C 0.10-0.20%, Mn 1.5-2.0%, P smaller than or equal to 0.015%, S smaller than or equal to 0.005%, Al 0.02-0.08%, N smaller than or equal to 0.005%, O smaller than or equal to 0.003%, Ti 0.10-0.20%, Nb 0.03-0.06%, V 0.20-0.40% and the balance Fe and inevitable impurities, and meanwhile the conditions required to be met are as follows: the sum of Nb and Ti is greater than or equal to 0.16% but is smaller than or equal to 0.23%, and (Ti-3.42N-3S) / 4+V / 4.24+Nb / 7.74 is greater than or equal to 0.065% but is smaller than or equal to 0.15%. The microstructure of the steel is ferrite, bainite and nanoscale precipitation carbide, wherein the equivalent grain size of the ferrite is smaller than or equal to 5 microns, the width of bainite battens is smaller than or equal to 0.5 micron, the tensile strength of the bainite battens is greater than or equal to 1180 MPa, the elongation is greater than or equal to 15%, the hole expansion rate is greater than or equal to 30%, and excellent strength, plasticity and burring matching are shown.

Description

technical field [0001] The invention belongs to the field of hot-rolled high-strength steel, and specifically relates to a 1180MPa-level precipitation-strengthened hot-rolled ultra-high-strength steel and a manufacturing method thereof. Background technique [0002] In the field of automobiles, especially passenger cars, high-strength thinning or lightweight automobile structures have become an important research direction for international automobile manufacturers. Different from the high-strength thinning and lightweight trends of passenger cars, the lightweight work of commercial vehicles is progressing very slowly. The main reason is that commercial vehicles are generally overloaded seriously, and the designers of commercial vehicles have a large design margin for the structure; at the same time, the commercial vehicles themselves and the load capacity are large, and sometimes the rigidity is difficult to guarantee after thinning with high-strength steel; On the one han...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C22C38/04C22C38/06C22C38/14C22C38/12C22C38/02C21D8/02

CPCC21D8/0226C21D2211/002C21D2211/005C22C38/02C22C38/04C22C38/06C22C38/12C22C38/14

Inventor 王焕荣杨阿娜王巍

Owner BAOSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com