Method for detecting bonding strength of babbitt metal and matrix

A technology of babbitt alloy and bonding strength, which is applied in the detection field, can solve the problems that the bonding strength of babbitt alloy and the matrix cannot be quantitatively characterized, the strength value cannot be given, and the sample preparation steps are complicated, so as to achieve easy sample processing and easy sampling Check and analyze the effect of short cycle time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions of the present invention will be further described below through specific embodiments.

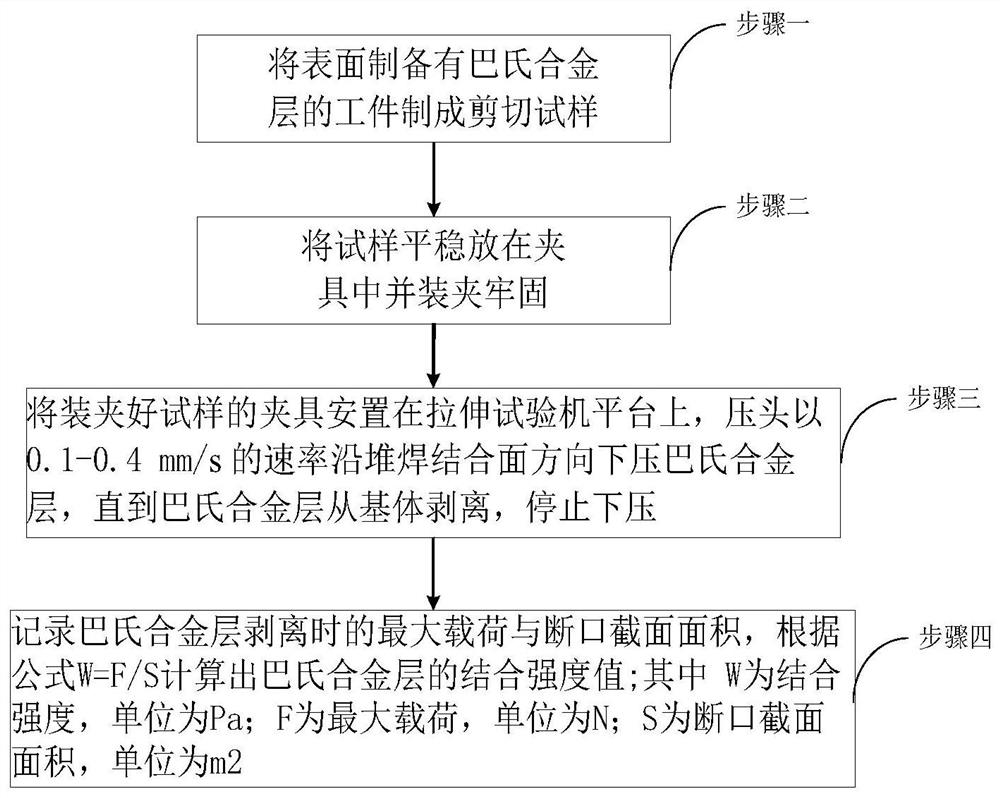

[0021] as attached figure 1 Shown, be the detection method of a kind of low-carbon steel surface welding babbitt alloy of the present invention and matrix bonding strength, comprise the steps:

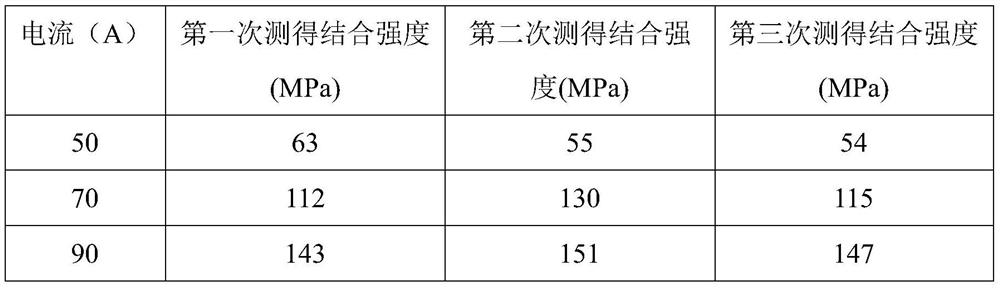

[0022] Step 1: Under the welding currents of 50A, 70A, and 90A, respectively, adopt the arc surfacing method to surfacing the Babbitt alloy layer with a thickness of 4mm on the surface of Q235B low-carbon steel with a thickness of 6mm. The welded workpiece is processed by wire cutting to make a cuboid sample with a length × width × thickness of 10mm × 5mm × 2mm.

[0023] Three workpieces were sampled for each welding current. The components of Babbitt welding consumables and low carbon steel used are shown in Table 1 and Table 2 respectively;

[0024] Step 2: Place the sample in the fixture stably and clamp it firmly;

[0025] Step 3: Place the fixture of the asse...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com