Large generator set bearing alloy casting and welding matching method

A technology for bearing alloys and generator sets, which is applied in the field of large-scale generator bearing bush manufacturing, can solve the problems of low production efficiency, high defective rate and repair rate of Babbitt alloys, and deformation of tile billets, etc., so as to improve production efficiency and product quality. The quality and product repair rate decrease, and the effect of reducing tile deformation and repair rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

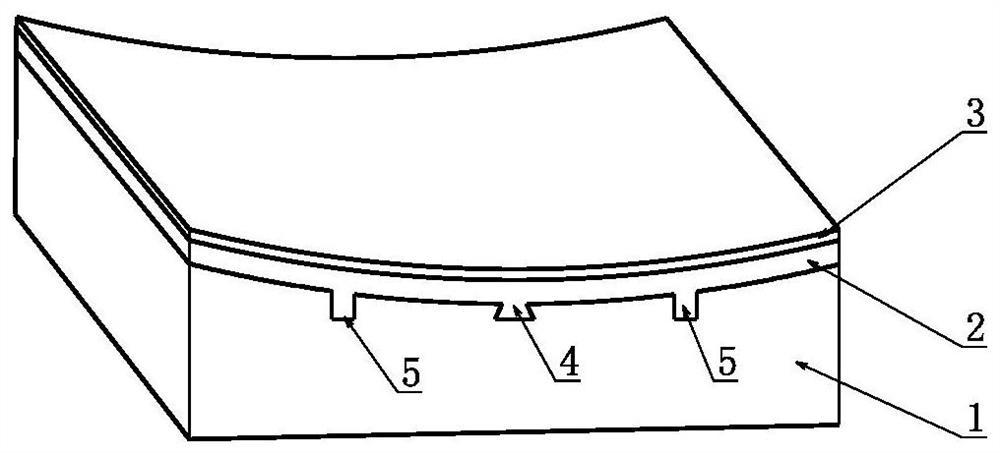

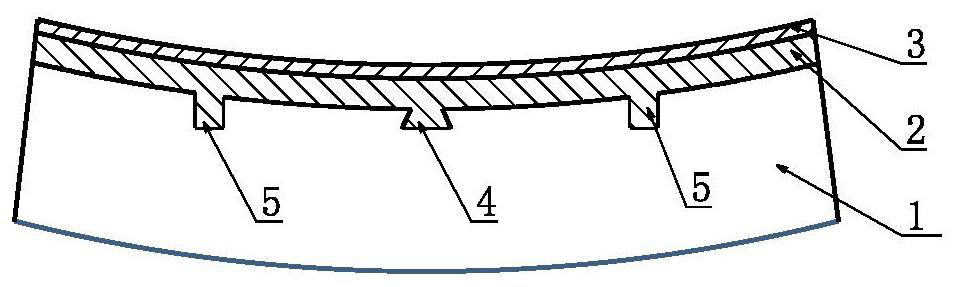

[0017] Clean up the oil, rust and processing burrs on the hanging casting surface of the tile blank 1, preheat the tile blank 1 to 160°C and keep it warm for 1 hour; brush the tin enamelling agent evenly on the hanging casting surface of the tile blank 1, and then soak the tile blank 1 Put it into the tin pot, the temperature of the tin liquid in the tin pot is 300°C, and the soaking time is 20 minutes. After the tile billet 1 is lifted out of the tin pot, the tin-coated surface presents a uniform silver-white mirror state; after the tile billet 1 comes out of the tin pot, it is quickly assembled, Put it together and fix it, the notch of the bearing bush completely falls into the notch of the mould; preheat the pouring spoon to 200°C, and cast a layer of Babbitt alloy 2 with a thickness of 3.5mm on the surface of the tile billet 1 by static casting method, and pre-cool after casting After 1 minute, open the cooling water pipe for cooling, the cooling time is 10 minutes, and the...

Embodiment 2

[0019] Clean up the oil stains, rust and processing burrs on the hanging casting surface of the tile blank 1, preheat the tile blank 1 to 180°C and keep it warm for 1.5h; brush the tin varnish evenly on the hanging casting surface of the tile blank 1, and then put the tile blank 1 Soak in a tin pot, the temperature of the tin liquid in the tin pot is 300°C, and the soaking time is 25 minutes. After the tile billet 1 is lifted out of the tin pot, the tin-coated surface presents a uniform silver-white mirror state; the tile billet 1 is assembled quickly after it comes out of the tin pot , and fix it, and the bearing bush notch completely falls into the mold notch; a layer of Babbitt alloy with a thickness of 4.0mm is cast on the surface of the tile billet 1 by centrifugal casting method, and before the tile billet 1 enters the centrifuge for pouring, the pouring spoon , ladle and sprue cup are preheated, the sprue cup is preheated to 180°C, the ladle is preheated to 280°C, the su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com