Oil film thickness measuring method of thrust bearing-babbitt metal tile for water turbine

A technology of oil film thickness and thrust bearing, which is applied in the direction of electric/magnetic thickness measurement, measuring device, electromagnetic measuring device, etc. It can solve the problems of measurement error, large error, measurement limitation of water turbine oil film thickness, etc., and achieve the effect of reducing the number of layouts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

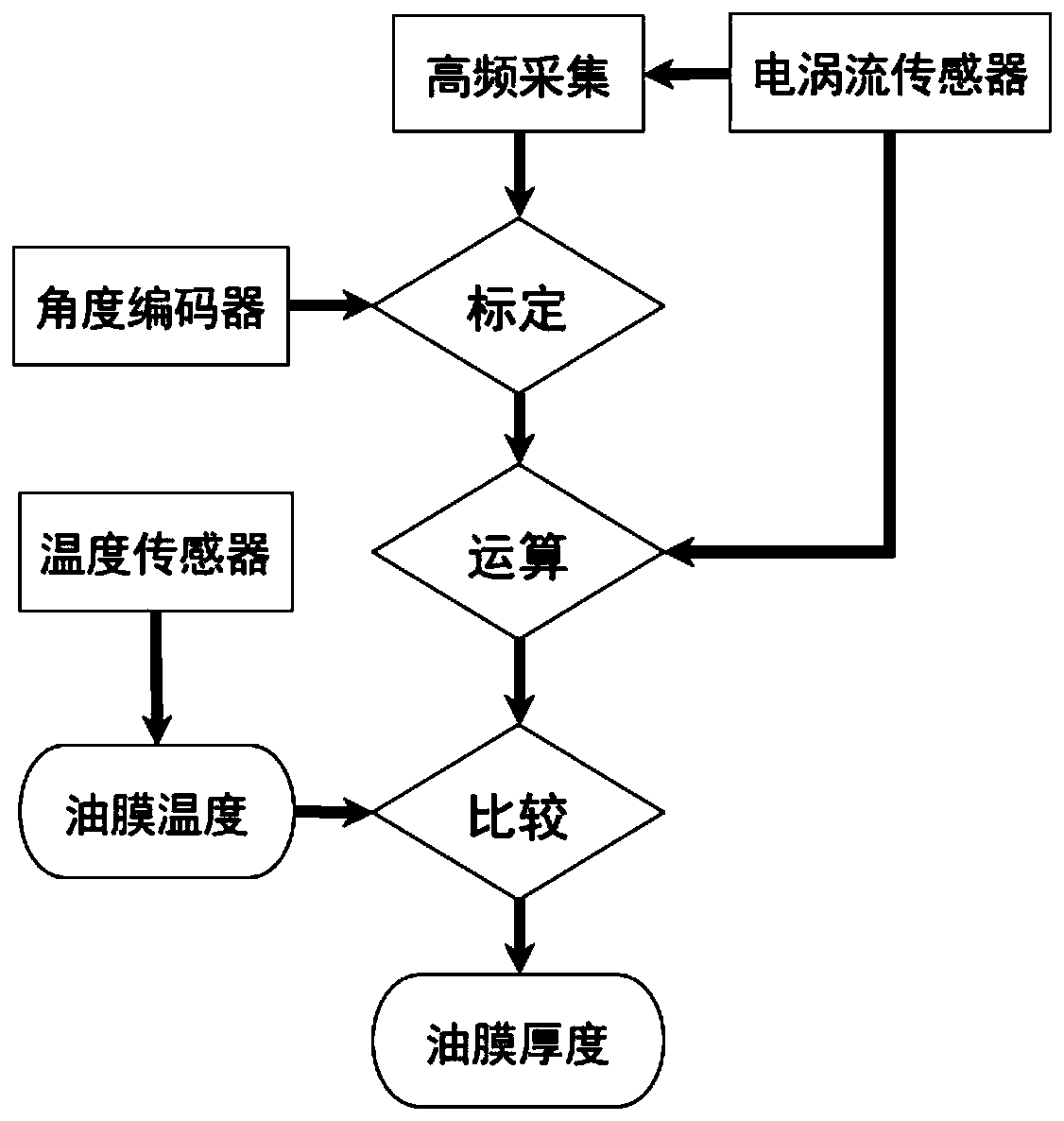

Method used

Image

Examples

Embodiment 1

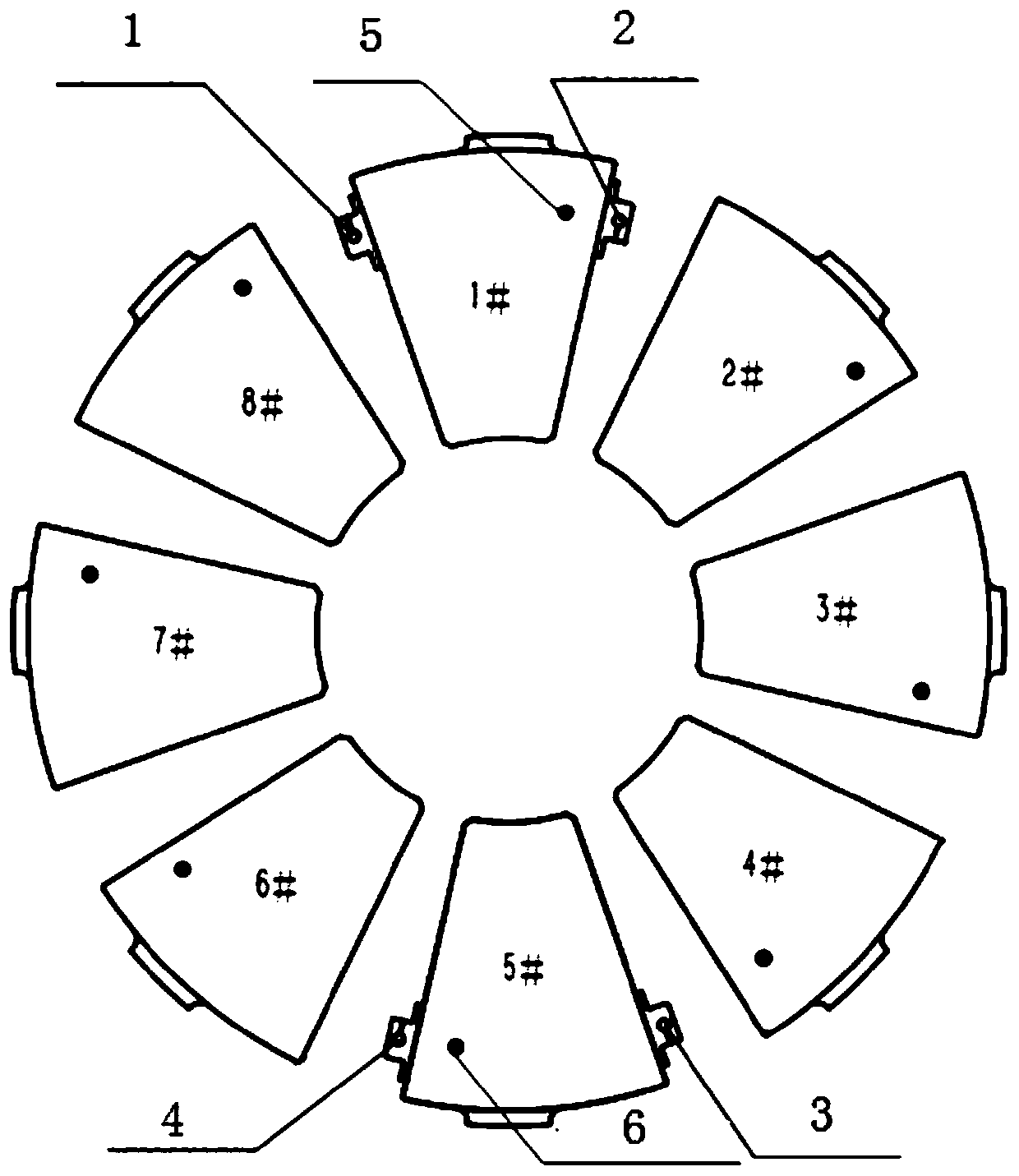

[0042] On the test unit with the installed sensor, the mirror plate is rotated by manual cranking, 22.5°, and after standing still for 10 minutes, the average value of the corresponding actual values of all eddy currents at 16 positions is recorded by the encoder as the initial value. 1 Oil inlet end eddy current displacement sensor 1, #1 oil outlet eddy current displacement sensor 2, #5 oil inlet eddy current displacement sensor 3, #5 oil outlet eddy current displacement sensor 4 The specific data measured are shown in the table 1

[0043] Table 1. The tie value of the actual value of the 16 position points after 3 weeks of manual cranking

[0044]

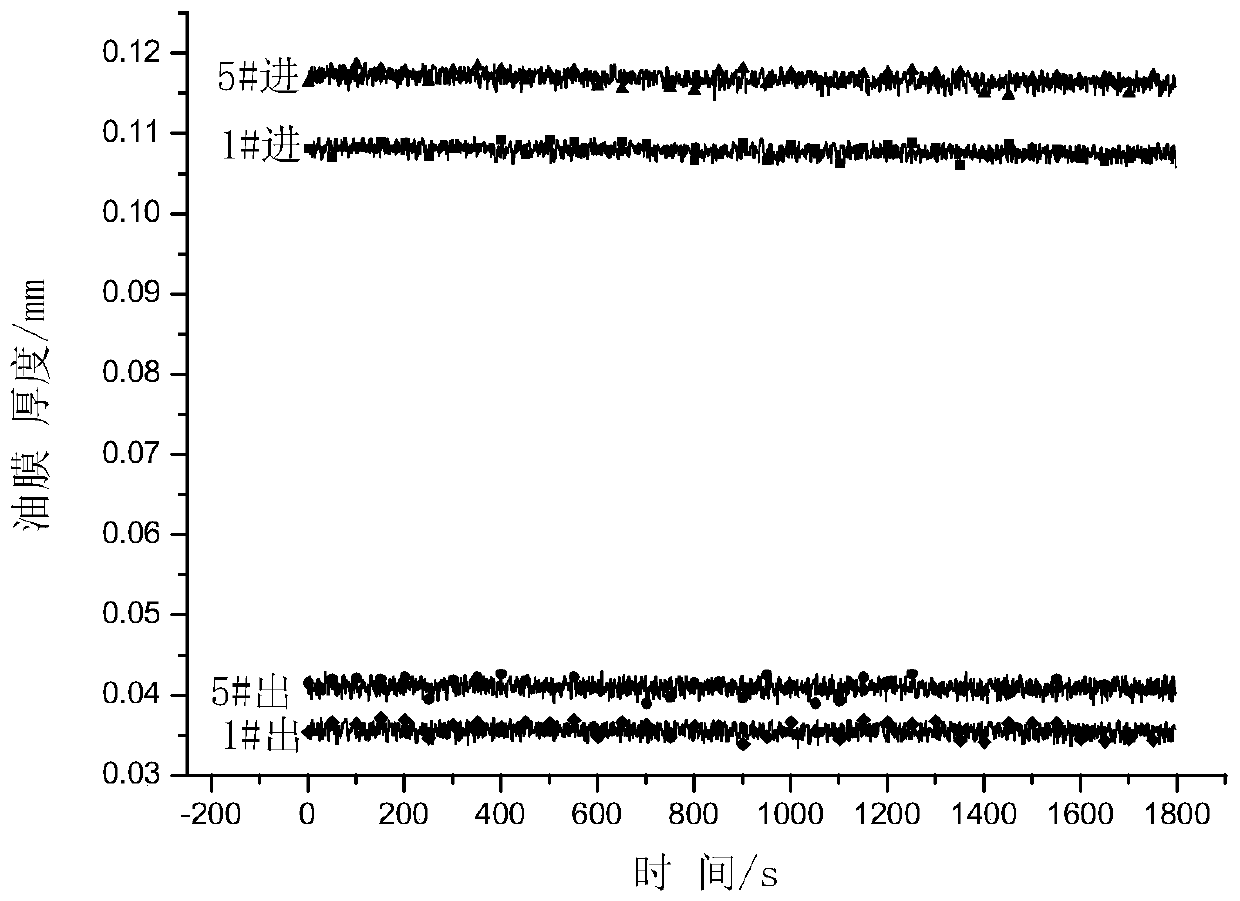

[0045] Operate at 600r / min with a load of 4MPa. When all parameters are stable, record the numerical curves measured by each sensor on the 1# tile as follows: image 3 shown.

Embodiment 2

[0047] This embodiment is intended to verify the correctness of calculating the oil film thickness of other tiles in step 5 based on the two babbitt tiles with eddy current displacement sensors.

[0048] On the basis of Example 1, run under the steady state, keep the rotating speed and load of the test unit constant, change the cooling capacity, make the oil film temperature change, and obtain such as Figure 4 The relationship curve between oil film thickness and oil film temperature of 1# tile thrust bearing is shown.

[0049] In Example 1 of image 3 Among them, the oil film thickness measured at the oil inlet end of 1# tile is 0.107mm, and the oil film thickness at the oil outlet end is 0.035mm. At this time, the oil film temperature of 1# measured by #1 temperature sensor 5 is 63.5°C; in the embodiment In 2, when the oil film temperature of the 1# tile is 63.5°C, the oil film temperature of the 5# tile measured by the #5 temperature sensor 6 on the host computer is 62.6°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com