Seismic energy dissipation system for T-shaped lever mechanism extended arm truss

A technology of outrigger truss and shock absorption system, applied in the direction of earthquake resistance, building components, building types, etc., can solve the problems of sudden change in the internal force of the core tube, the increase of the overall stiffness, and the increase of the seismic action, so as to reduce the project cost and increase the additional cost. Damping ratio, the effect of increasing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, where the schematic embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

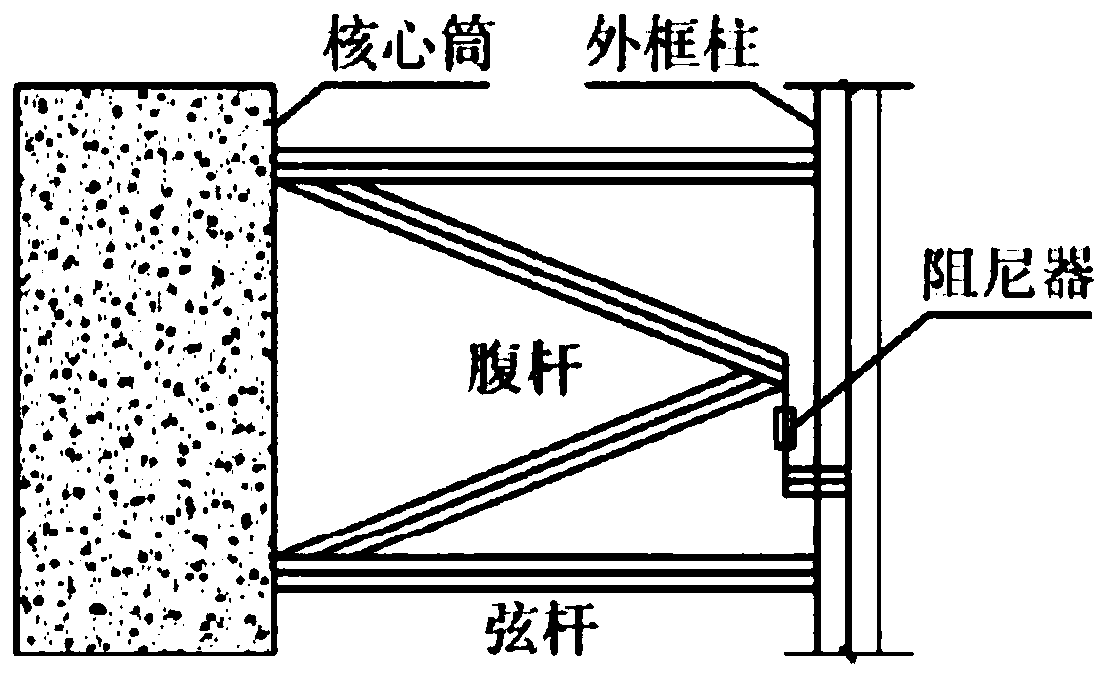

[0034] like Figure 4 As shown, a T-shaped lever mechanism outrigger truss energy dissipation and shock absorption system includes an outrigger truss arranged between the core tube 2 and the frame column 1, and the end of the outrigger truss is connected with a T-shaped lever 5 and a damper 9 hinged damping mechanisms; the T-shaped lever 5 includes a T-shaped lever cross bar 5-1 and a T-shaped lever vertical bar 5-2, wherein the right end of the T-shaped lever cross bar 5-1 is hinged with the outer end of the outrigger truss, and the T-shaped The left end of the lever cross bar 5-1 is hinged with the frame column 1; the T-shaped lever vertical bar 5-2 is hinged with the left end of the da...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com