A laser additive manufacturing method for tin-based babbitt alloy components

A technology of tin-based Babbitt alloy and manufacturing method, which is applied in the processing field of metal components, can solve the problems of low forming precision, complex process, and coarse structure, and achieve the effect of no increase in structural complexity and short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

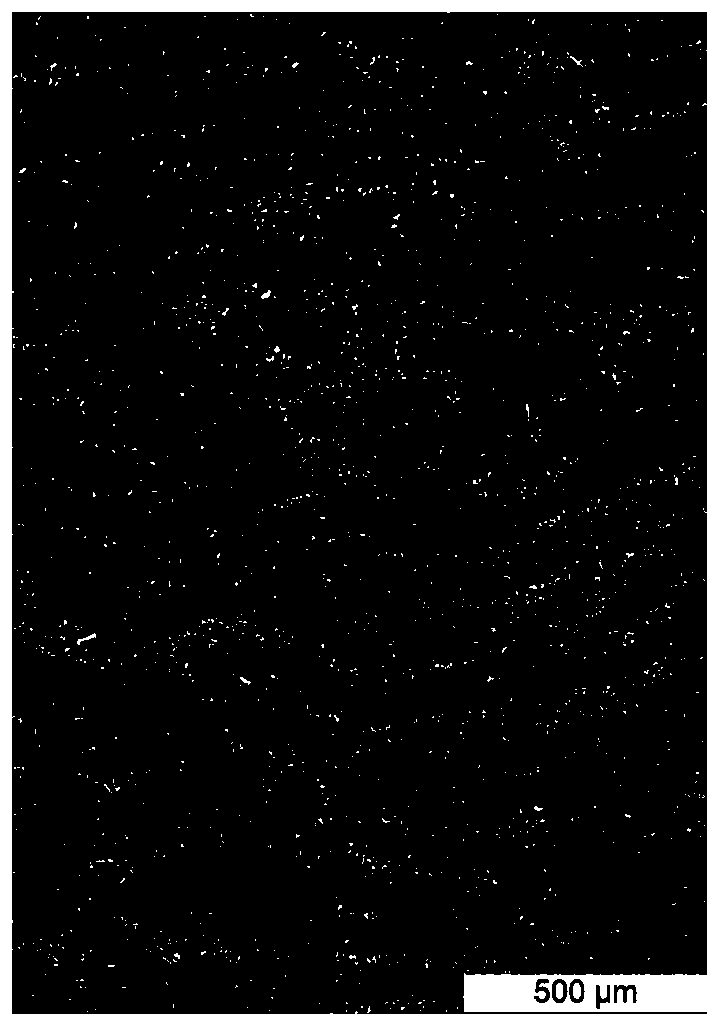

Image

Examples

Embodiment 1

[0025] 1. Use the SolidWorks 3D drawing software to design a wall, and use the slicing software to slice it. The thickness of the sliced layer is 0.1mm.

[0026] 2. Use a tin-plated steel plate as the substrate, the thickness of the tin-plated layer is 0.1mm, and place it on an electric heating plate with a temperature of 100 °C.

[0027] 3. The composition of tin-based Babbitt alloy powder is 15% antimony, 4% copper, and the balance of tin, and the particle size is 150 mesh. Lay the tin-based Babbitt alloy powder on the surface of the substrate in step 2 with a thickness of 0.1mm.

[0028] 4. Use the first two-dimensional slicing pattern in step 1 to control the light output and running path of the laser beam, and form the first laser cladding layer in the selected area under the heating effect of the 45W laser beam.

[0029] 5. Lower the substrate by 0.1 mm, spread powder according to step 3, and use the second two-dimensional slice pattern in step 1 to control the laser ...

Embodiment 2

[0032] 1. Use the SolidWorks 3D drawing software to design a wall, and use the slicing software to slice it. The thickness of the sliced layer is 0.02mm.

[0033] 2. Use tin-plated steel plate on the surface as the substrate, the thickness of the tin-plated layer is 0.02mm, and place it on an electric heating plate with a temperature of 50°C.

[0034] 3. The composition of tin-based Babbitt alloy powder is 6% antimony, 6% copper, the balance of tin, and the particle size is 300 mesh. Lay the tin-based Babbitt alloy powder on the surface of the substrate in step 2 with a thickness of 0.02 mm.

[0035] 4. Use the first two-dimensional slicing pattern in step 1 to control the light output and running path of the laser beam, and form the first laser cladding layer in the selected area under the heating effect of the 20W laser beam.

[0036] 5. Lower the substrate by 0.02mm, spread powder according to step 3, use the second two-dimensional slice pattern in step 1 to control the ...

Embodiment 3

[0039] 1. Use the SolidWorks 3D drawing software to design a wall, and use the slicing software to slice. The thickness of the slicing layer is 0.2mm.

[0040] 2. Use a tin-plated steel plate as the substrate, the thickness of the tin-plated layer is 0.2mm, and place it on an electric heating plate with a temperature of 150 °C.

[0041] 3. The composition of tin-based Babbitt alloy powder is 3% antimony, 2% copper, and the balance of tin, and the particle size is 80 mesh. Lay the tin-based Babbitt alloy powder on the surface of the substrate in step 2 with a thickness of 0.2 mm.

[0042] 4. Use the first two-dimensional slicing pattern in step 1 to control the light output and running path of the laser beam, and form the first laser cladding layer in the selected area under the heating action of the 100W laser beam.

[0043] 5. Lower the substrate by 0.2mm, spread powder according to step 3, and use the second two-dimensional slice pattern in step 1 to control the laser beam ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com