Device and method for quickly manufacturing babbitt metal bearing bush

A technology of babbitt alloy and bearing pads, which is applied in the field of rapid manufacturing of babbitt alloy bearing pads, can solve problems such as complex bearing pad manufacturing processes, and achieve the effects of facilitating quality control, reducing production processes, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

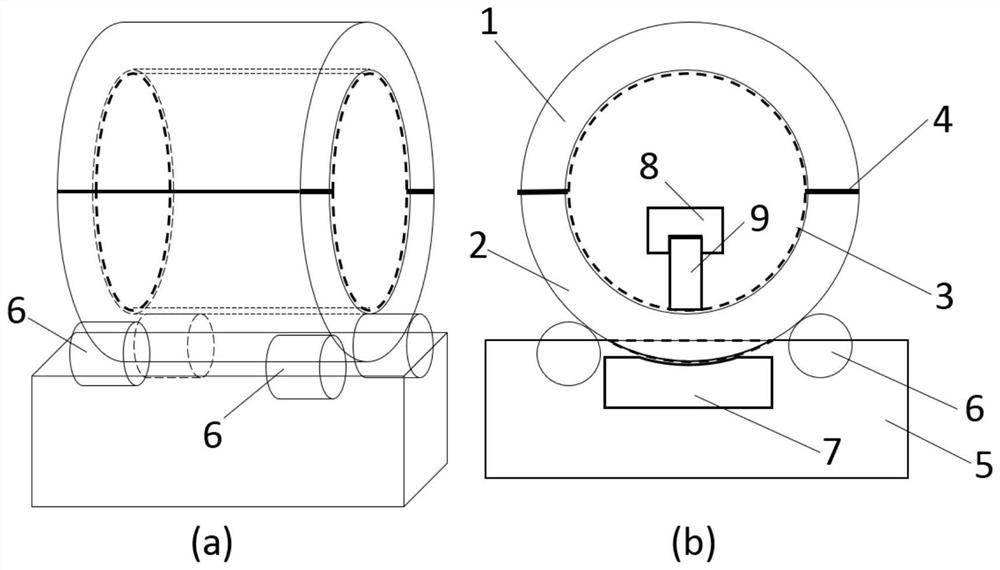

[0082] This embodiment provides a method for rapidly manufacturing a babbitt alloy bearing bush, including the following steps:

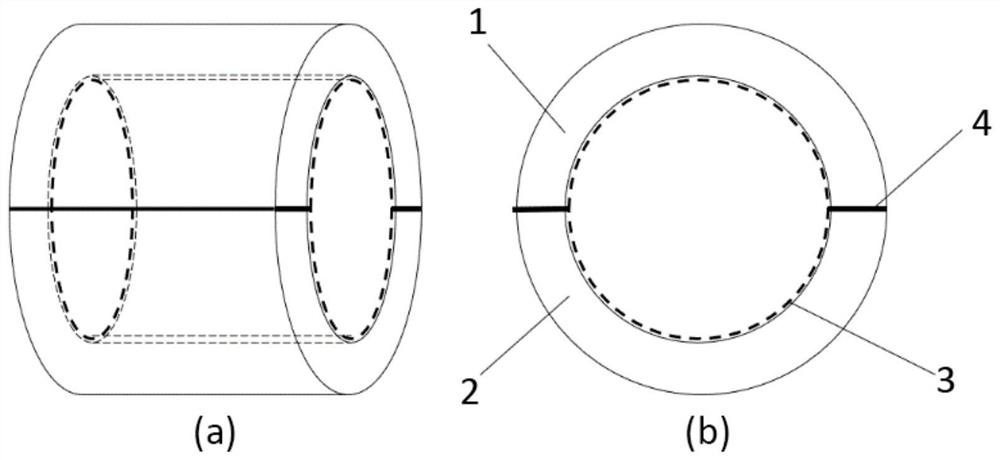

[0083] (1) Pretreat the bearing bush blank to get the bearing bush

[0084] a. Processing the commercially available bearing blanks of standard size, including the upper bearing 1 and the lower bearing 2, by lathes, milling machines, etc., to remove burrs, flashes, etc.;

[0085] b. Put the rough bearing bush obtained in step a into a heating furnace and heat it to 400°C, then heat it to 700°C and keep it warm for 6 hours; take the bearing bush out of the heating furnace with iron clips, and let it cool naturally to room temperature;

[0086] c. Use a grinder to grind the inside of the bearing bush obtained in step b to remove the oxide layer. After grinding, clean the bearing bush with a saturated zinc chloride solution, that is, apply the saturated zinc chloride solution to the inside of the bearing bush;

[0087] d. Preheat the bearing bush blank ...

Embodiment 2

[0093] The present embodiment refers to the preparation method of Example 1, the difference is only in:

[0094] In step (2), after assembly, a pressure of 2000N is applied between the first electrode and the second electrode and a direct current of 380V and 10A is passed;

[0095] The linear speed of rotation of the bearing bush is 0.2 m / min.

Embodiment 3

[0097] The present embodiment refers to the preparation method of Example 1, the difference is only in:

[0098] In step (2), after assembly, a pressure of 3000N is applied between the first electrode and the second electrode and a direct current of 380V and 20A is passed;

[0099] The linear speed of rotation of the bearing bush is 0.5 m / min.

[0100] In the present invention, the Babbitt alloy ingot is directly placed in the inner cavity of the bearing bush through the second electrode, and there is a gap between the Babbitt alloy ingot and the inner surface of the bearing bush. According to Joule's law, the temperature at the gap rises first, making the casting The contact position between the ingot and the inner surface of the bearing bush is melted to the inner surface of the bearing bush, and welding is realized after cooling; there is no need to pre-melt Babbitt alloy ingots, etc., which reduces the large energy consumption caused by traditional overall heating and save...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com