Completely biodegradable material filling master batch and preparation method thereof

A biodegradable material and filler masterbatch technology, applied in the field of filler masterbatch and materials, can solve the problems of high price, environmental pollution, and not obvious cost advantages, and achieve the effects of good mechanical properties, improved processing environment, and outstanding cost advantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

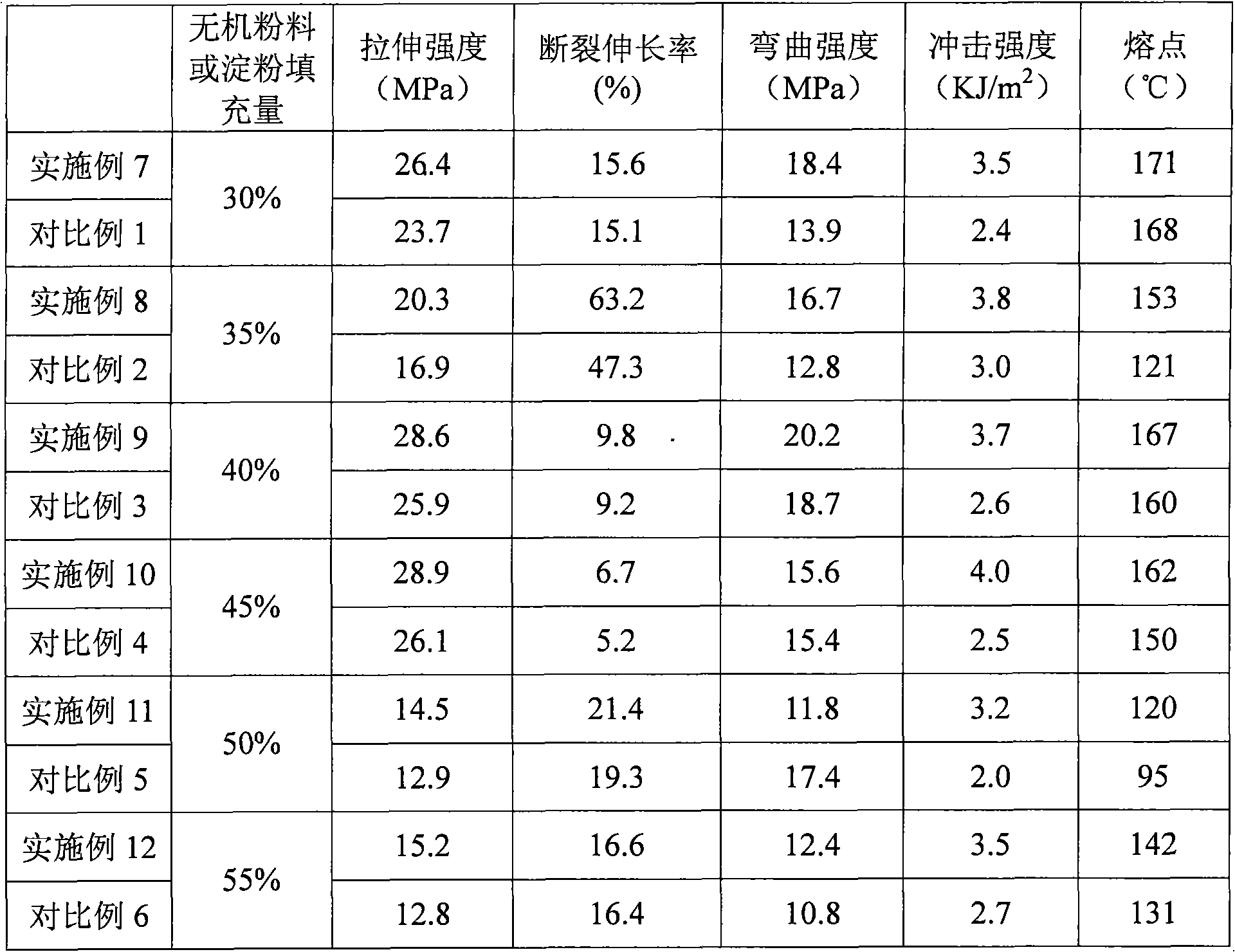

Examples

Embodiment 1

[0021] The fully biodegradable material filling masterbatch of the present embodiment, by weight, each component content is respectively: PHB (polyhydroxybutyrate) content 22%, calcium carbonate 70%, antioxidant tris(2, 0.3% of 4-di-tert-butylphenyl) ester, 3.5% of dispersant stearic acid, 2.2% of lubricant ethylene wax, and 2% of interfacial modifier calcium stearate.

Embodiment 2

[0023] The fully biodegradable material filling masterbatch of this embodiment, by weight, the content of each component is: P3HB4HB (poly 3-hydroxybutyrate-4-hydroxybutyrate, wherein the molar content of 4HB is 5%) content 35%, talc powder 62%, antioxidant tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester 0.5%, dispersant low molecular weight PE 2.0%, lubricating Agent paraffin 0.5%.

Embodiment 3

[0025] The fully biodegradable material filling masterbatch of the present embodiment, by weight, each component content is respectively: PHBV (polyhydroxybutyrate valerate, wherein HV molar content is 10%) content 10%, barium sulfate is 80% %, antioxidant tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester 2.5%, dispersant stearic acid 3.0%, lubricant paraffin 1.5%, interface modification Agent titanate 3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com