Babbitt metal casting solvent, preparation method and Babbitt metal casting method

A technology of babbitt alloy and preparation method, applied in the field of babbitt alloy casting flux, can solve the problems of high price, complicated process, high cost, etc., and achieve the effects of low cost, simple process and good bonding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

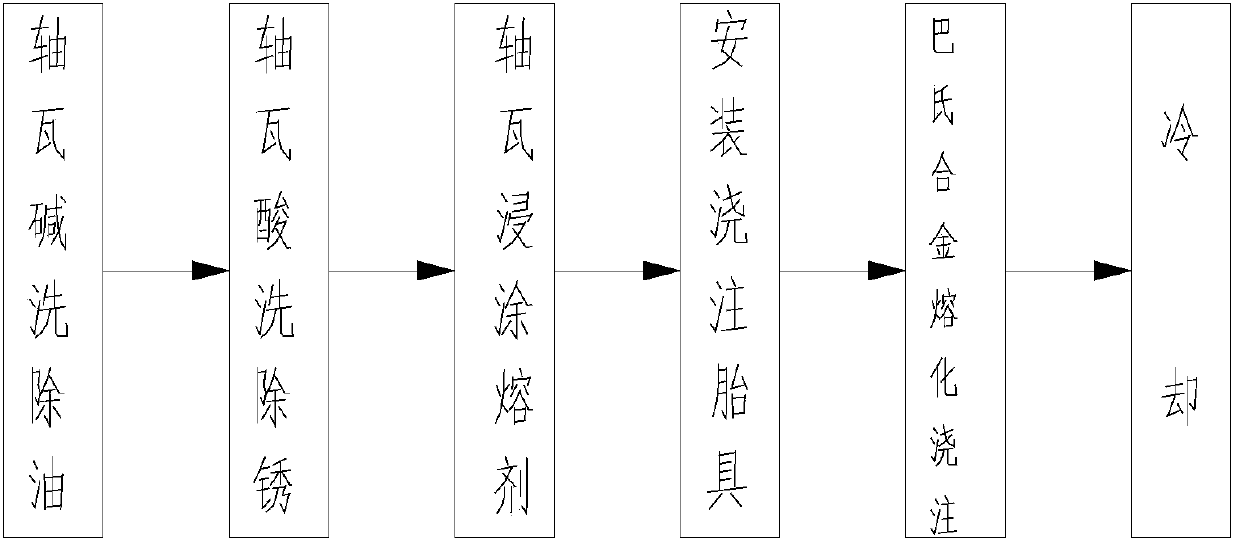

Method used

Image

Examples

Embodiment 1

[0022] Embodiment one : The mass percent content of each component in the Babbitt casting flux is: zinc chloride ZnCl 2 : 80%, stannous chloride SnCl 2H 2 O: 9%, CuCl 2H2O: 1%, industrial hydrochloric acid: 7%, water H2O: 3%.

Embodiment 2

[0023] Embodiment two : The mass percent content of each component in the Babbitt casting flux is: zinc chloride ZnCl 2 :77%, stannous chloride dihydrate SnCl 2H 2 O: 10%, copper chloride dihydrate CuCl 2H 2 O: 2%, industrial hydrochloric acid: 8%, water H 2 O: 3﹪.

Embodiment 3

[0024] Embodiment three : The mass percent content of each component in the Babbitt casting flux is: zinc chloride ZnCl 2 : 81%, stannous chloride dihydrate SnCl 2H 2 O:8﹪, high copper chloride dihydrate CuCl·2H 2 O: 1%, industrial hydrochloric acid: 6%, water H 2 O: 4%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com