Stannum-based composite babbit metal and method for preparing welding wire

A technology of composite babbitt alloy and babbitt alloy, which is applied in the direction of metal processing equipment, welding medium, manufacturing tools, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A tin-based composite babbitt alloy, comprising a babbitt alloy matrix and magnetic particles, wherein the weight percentage of the magnetic particles is 1 to 10%, and the balance is the babbitt alloy matrix, and the babbitt alloy matrix includes: Sb, Cu and Sn, its weight percentage: Sb 5-13%, Cu 1-10%, Sn balance. The magnetic particles at least include Fe, Co, Ni, Fe 2 o 3 , Fe 3 o 4 One of the particles, the particle size of the magnetic particles is 0.05-50 μm. In this embodiment, the weight percentage of magnetic particles is 1%, 6% or 10%; the weight percentage of Sb, Cu and Sn in the Babbitt alloy matrix is Sb 5%, Cu 1%, Sn balance, Sb 7% , Cu 4%, Sn balance, or, Sb13%, Cu 10%, Sn balance; the magnetic particles can be Fe, Co, Ni, Fe 2 o 3 , Fe 3 o 4 One of the particles, it can also be Fe, Co, Ni, Fe 2 o 3 , Fe 3 o 4 Any combination of particles; magnetic particles with a particle size of 0.05, 15 or 50 μm.

Embodiment 2

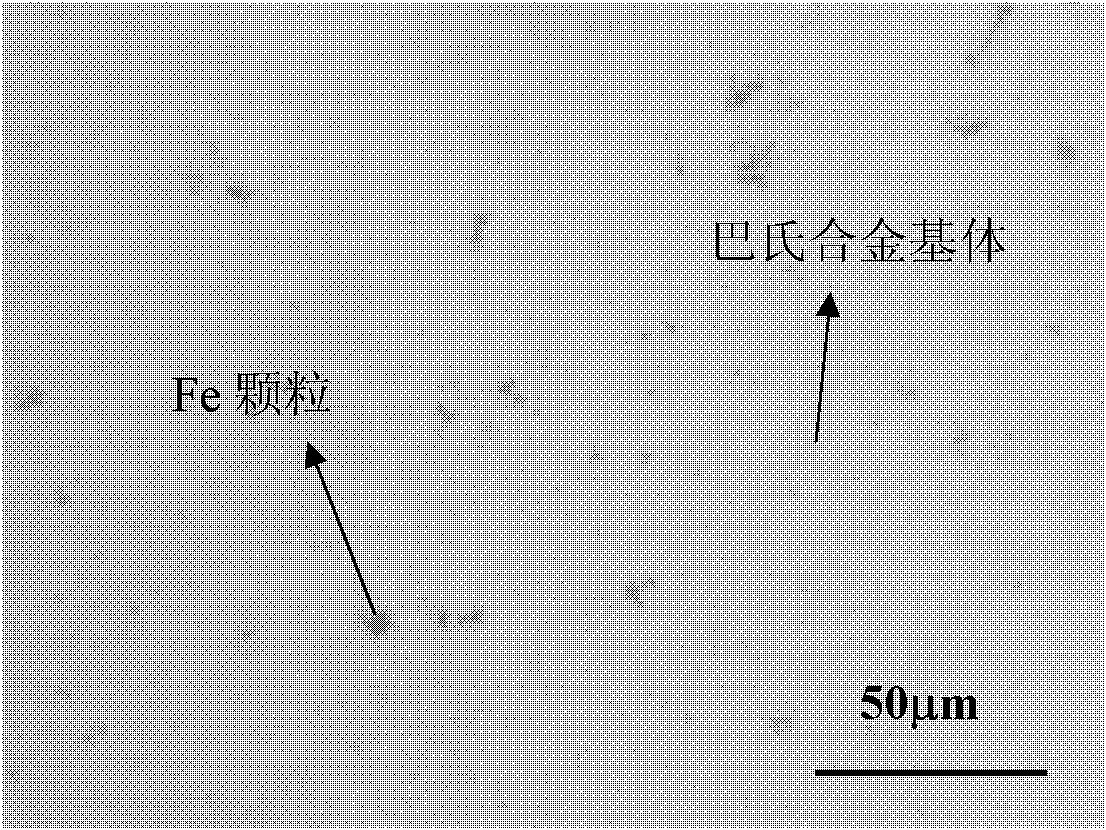

[0032] A tin-based composite babbitt alloy, comprising a babbitt alloy matrix and magnetic particles, wherein the weight percentage of the magnetic particles is 2%, and the balance is the babbitt alloy matrix, and the grade of the babbitt alloy matrix is ZCHSnSb11-6, The magnetic particles are Fe, and the particle diameter of the magnetic particles is 30 μm. refer to figure 1 , dark Fe particles are evenly distributed on the light-colored Babbitt alloy matrix. refer to Figure 6 Compared with the Babbitt alloy without Fe particles, the wear volume of Babbitt alloy containing 2% Fe particles is reduced by 14.3%, and the wear resistance is improved. The wear test is carried out on the MM-200 wear testing machine, using GCr15 steel grinding wheel Oil grinding, load 300N, sliding line speed 1m / s, wear time 20min.

Embodiment 3

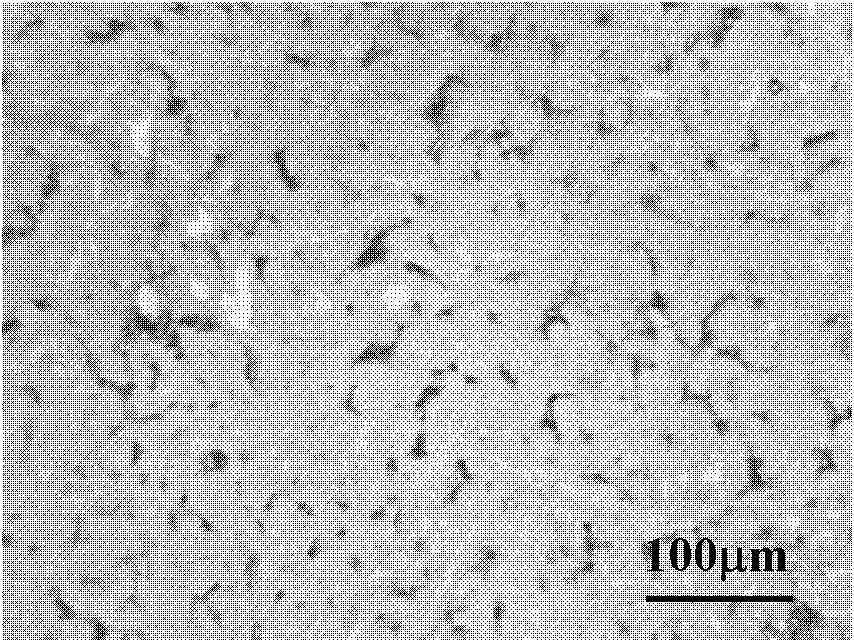

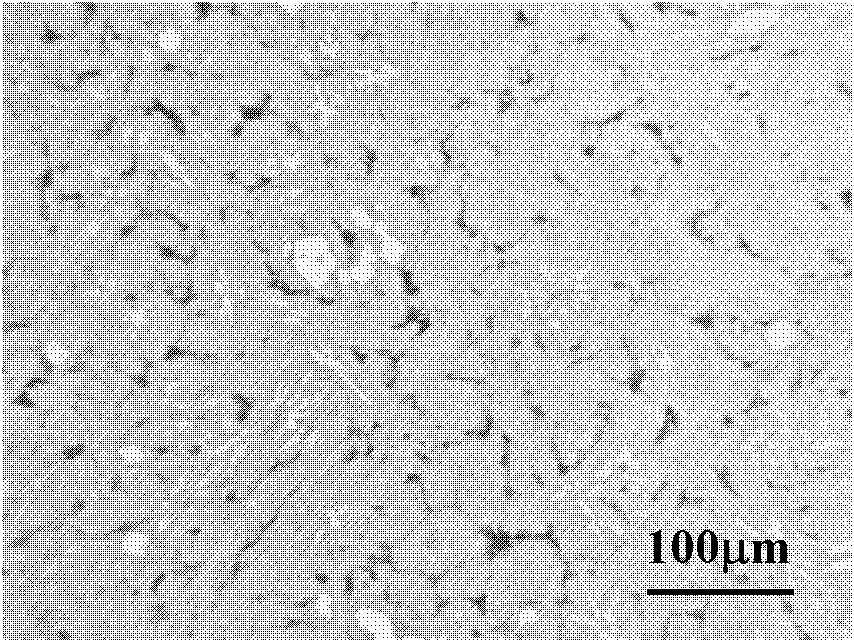

[0034] A tin-based composite babbitt alloy, comprising a babbitt alloy matrix and magnetic particles, wherein the weight percentage of the magnetic particles is 4%, and the balance is a babbitt alloy matrix, and the grade of the babbitt alloy matrix is ZCHSnSb11-6, The magnetic particles are Fe, and the particle diameter of the magnetic particles is 30 μm. refer to figure 2 , in the Babbitt alloy structure, the black needle-like or star-like crystals are ε(Cu6Sn5) phase, coarse and unevenly distributed, refer to image 3 , In Babbitt alloy containing 4% Fe particles, the black ε (Cu6Sn5) phase is refined and evenly distributed. refer to Figure 4 , when the tin-based babbitt alloy is wetted on the iron sheet, the magnetic field has no effect on the babbitt alloy, refer to Figure 5 , When the tin-based babbitt alloy containing 4% Fe particles is wetted on the iron sheet, after the magnetic field acts, the spreading area increases and the wettability improves. refer to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com