Structure for ensuring requirement for high coaxiality of large-diameter precision pipe body workpiece and method

A precision tube and large-diameter technology, applied in the field of mechanical manufacturing and processing, to achieve the effect of improving clamping accuracy, reducing the number and cost of tooling manufacturing, and eliminating system errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

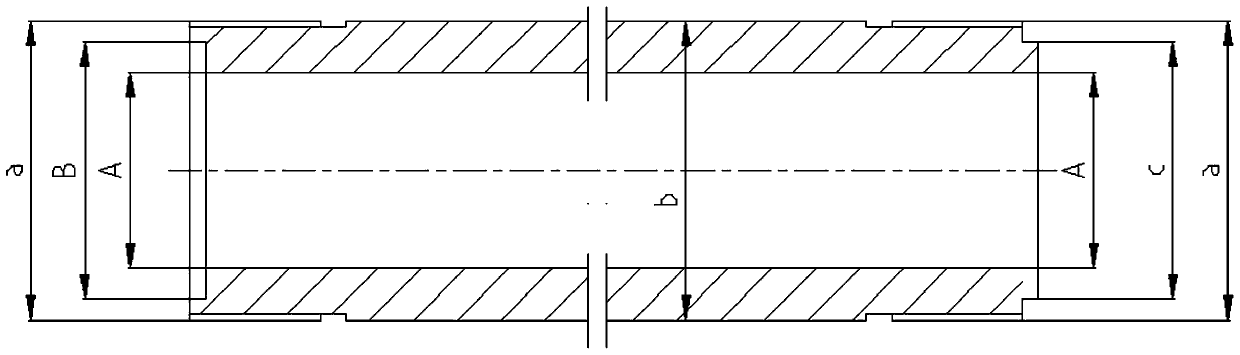

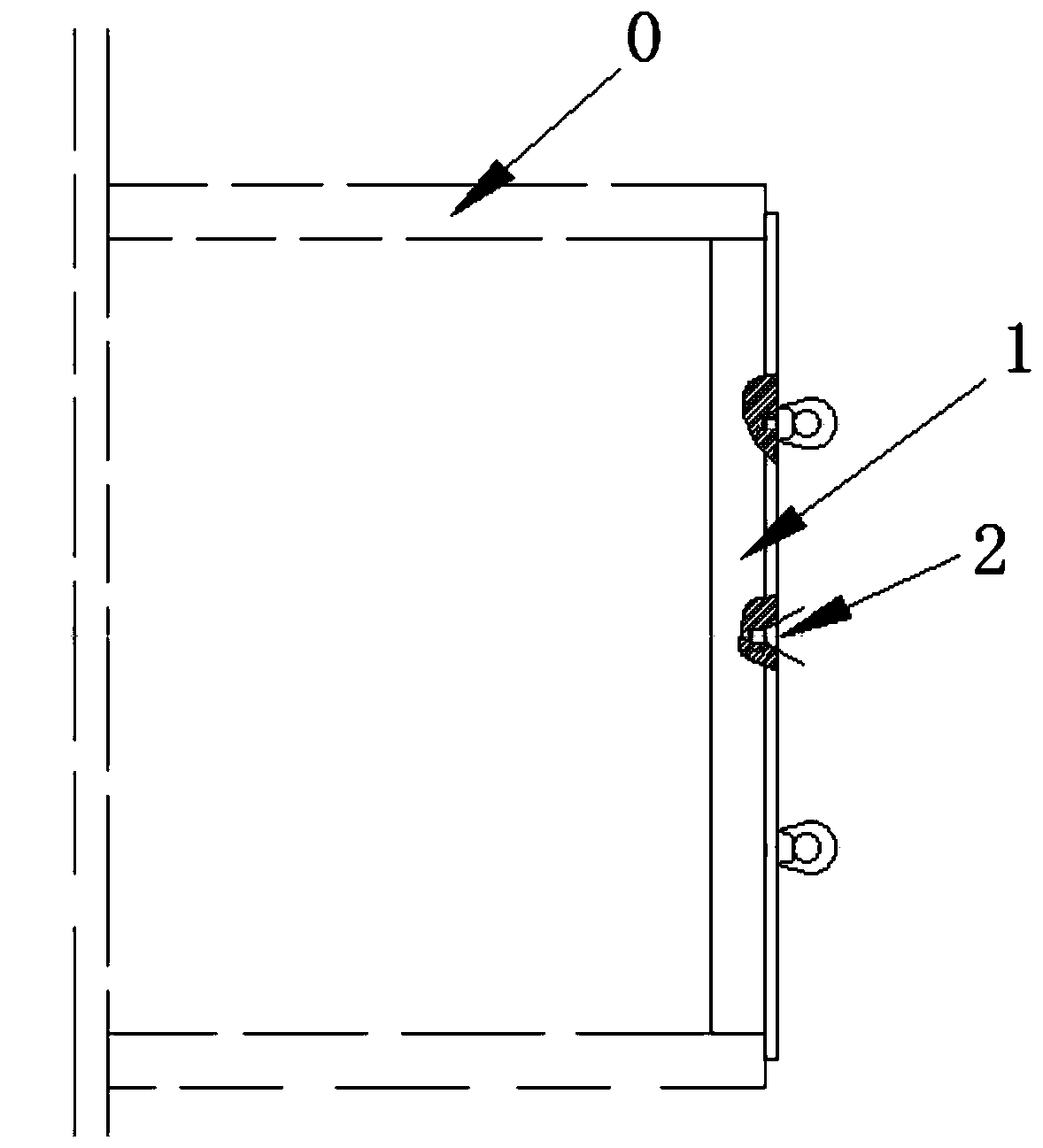

[0031] to combine figure 1 and figure 2 , the main hole A uses T2280 deep hole boring machine, follow the principle of inner hole and outer circle as the reference each other, and divide into rough, semi-finishing, finishing and process heat treatment and other processes. The grinding method ensures the dimensional accuracy and shape and position accuracy requirements of the deep hole. The specific embodiment of the present invention focuses on how to complete the finishing of the outer circle, the two ends of the thread and the inner / outer shoulder circle based on the main hole A after finishing, and ensure the high coaxiality requirement with the main hole A.

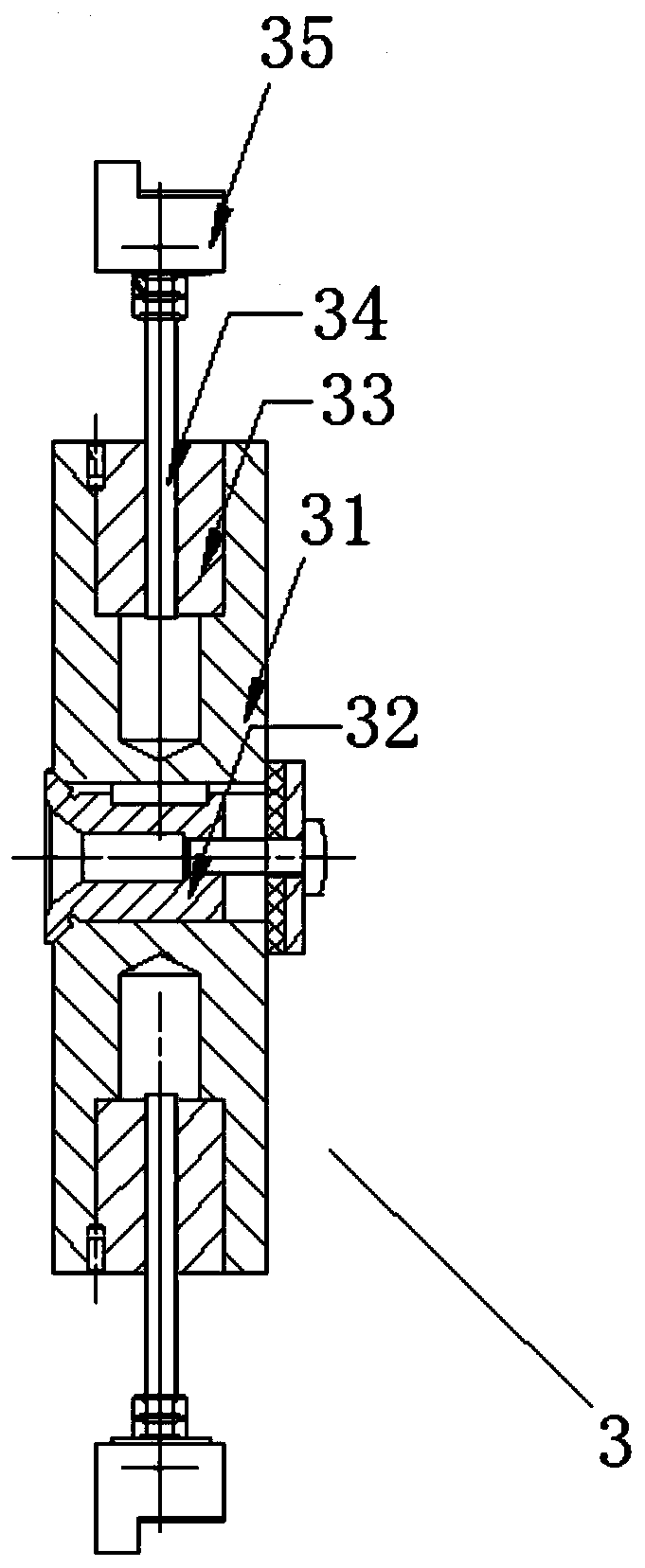

[0032] The structure of the present invention that guarantees high coaxiality requirements for large-diameter precision tubular wor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com