Split type bearing bush centrifugal casting method

A centrifugal casting and split technology, applied to bearing components, shafts and bearings, mechanical equipment, etc., can solve problems such as poor quality of bearing pads, weak bonding, cracks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

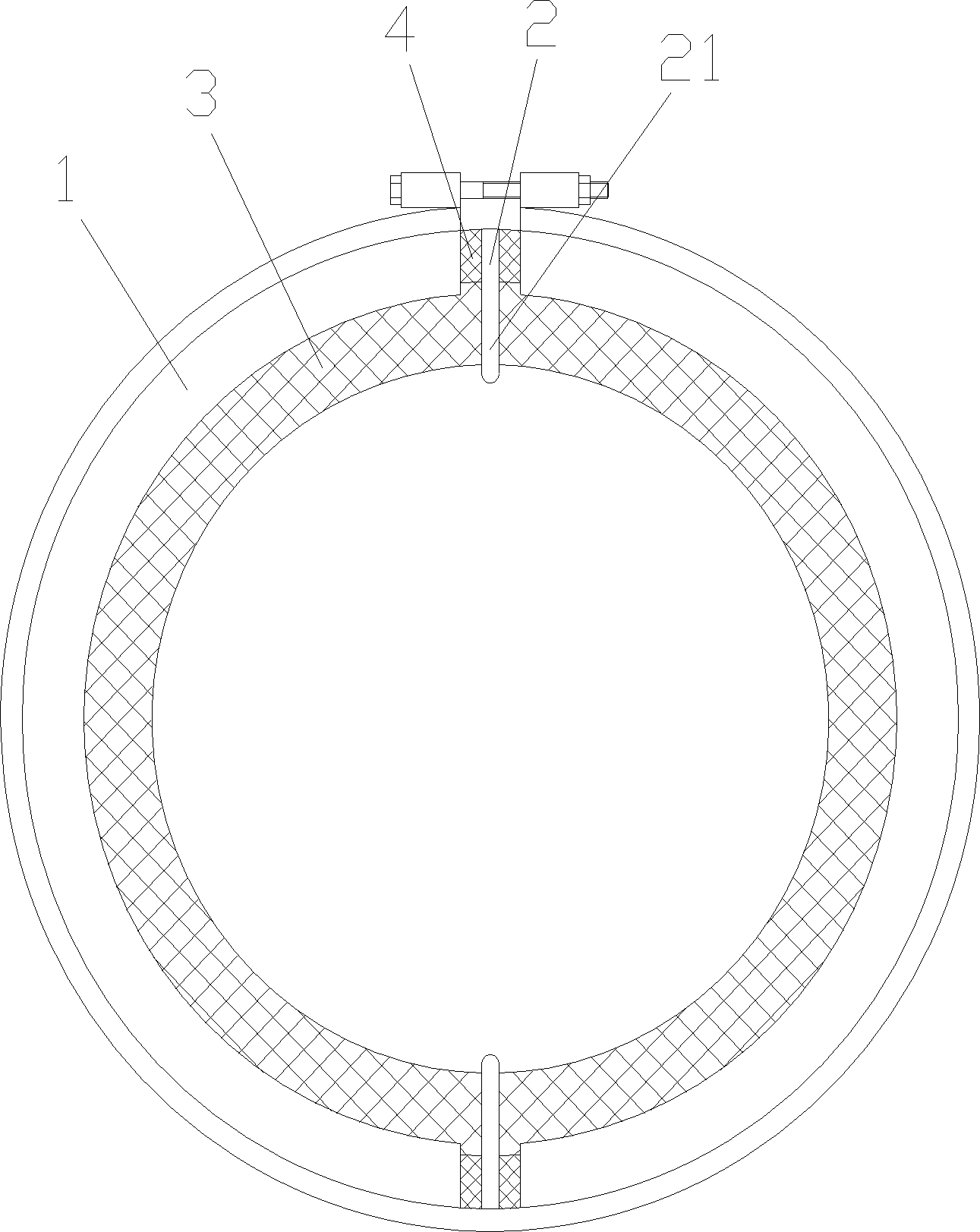

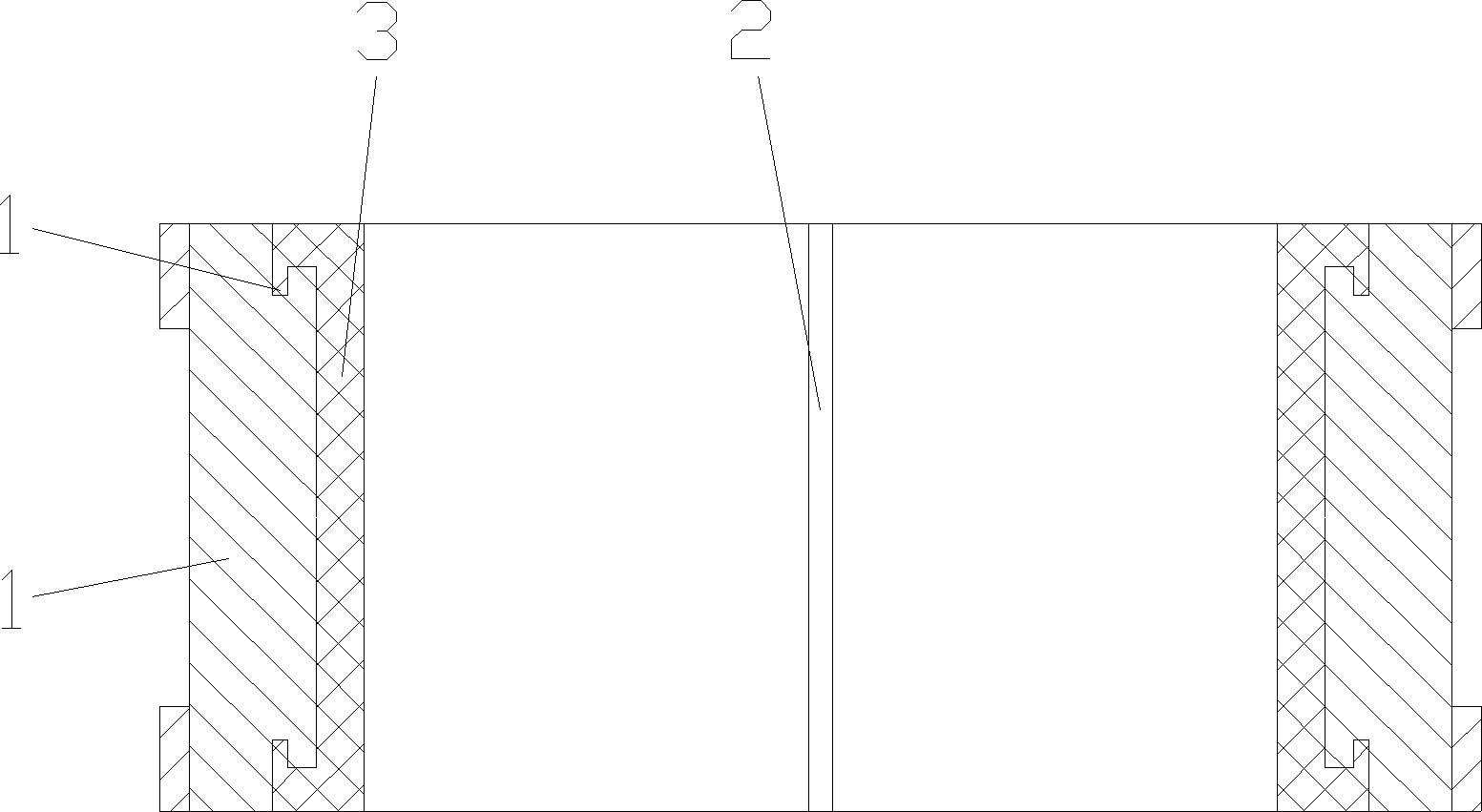

[0019] figure 1 A schematic diagram of the tile structure, figure 2 for figure 1 As shown in the figure: the centrifugal casting method of the split bearing bush in this embodiment includes the preparation of molten anti-friction material, treatment of the tile blank, centrifugal casting and subsequent processing. The tile blank 1 is fastened by two half tiles and then fixed made, specifically including the following steps:

[0020] a. preparing a molten anti-friction material for pouring into the interior of the tile 1 to form the lining 3;

[0021] b. An annular groove 11 is processed coaxially with the tile blank 1 on both ends of the tile blank 1. The side wall of the tile axis to ensure that the molten anti-friction material fills the annular groove 11 under the action of centrifugal force;

[0022] c. A spacer 2 is provided at the joint surface of the two half-tiles that are fastened together, and the spacer 2 extends toward the axis of the tile blank to form a leng...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com