Technique for heating liquid steel scoria

A technology of liquid steel slag and thermal braising, which is applied in the field of iron and steel smelting production, can solve the problems of increased processing difficulty, dust pollution environment, large floor area, etc., to reduce the difficulty of subsequent processing, reduce large pieces of steel slag, and improve metal recovery rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

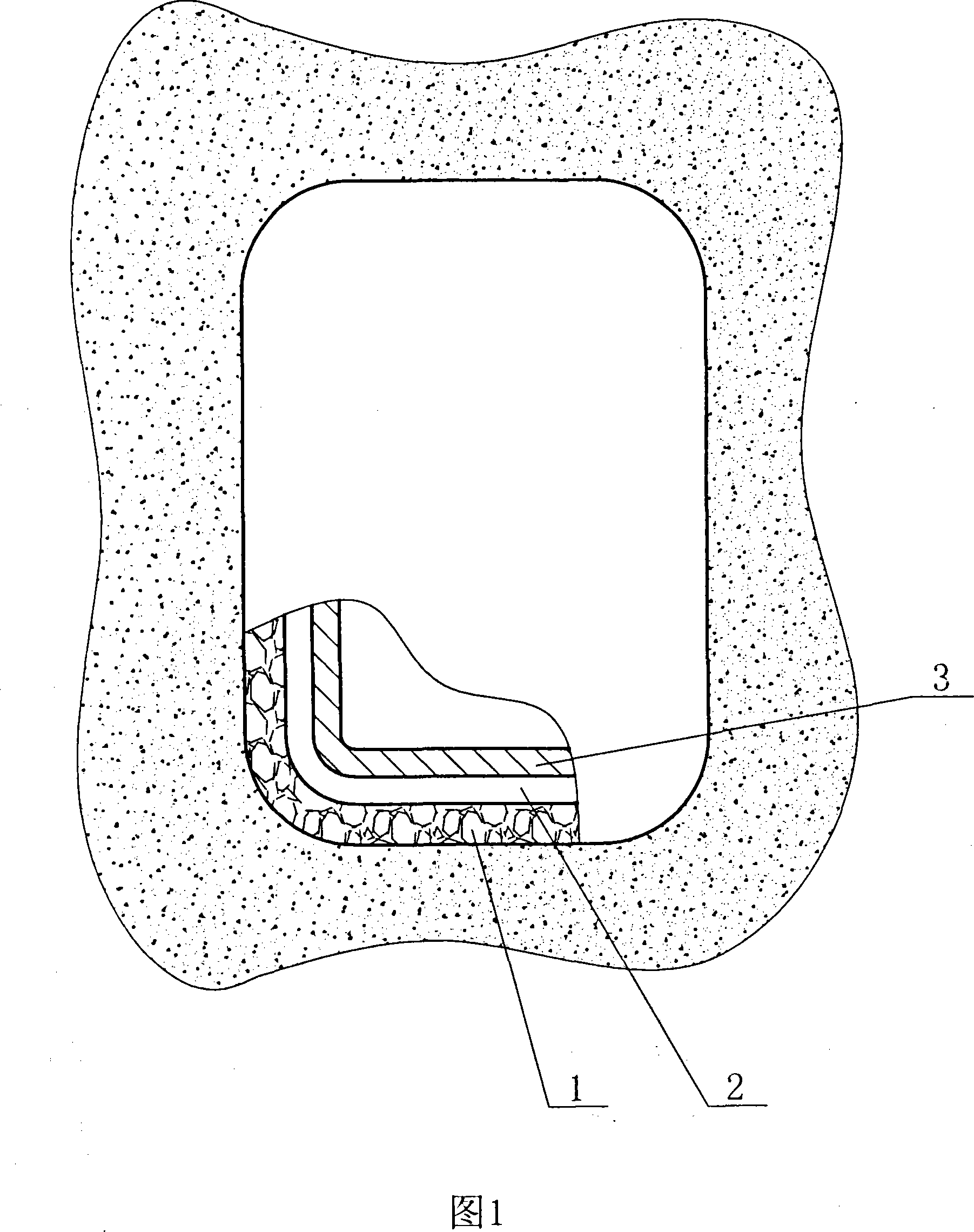

[0012] The process of the invention is to directly send the waste produced by steelmaking from the steelmaking furnace to the hot stewing tank, and realize fine crushing of the steel slag in the hot stewing tank.

[0013] Except that the structure of the hot stewing pot of the present invention is changed with that of the known technology, other structures are the same. It is resistant to the temperature of liquid steel slag. At the same time, a cavity is provided between the inner wall of the steel billet and the outer concrete wall. The cavity is used to alleviate the problem that the tank wall and the concrete wall are easily damaged during high temperature transmission.

[0014] The volume of the hot stewing tank described in the present invention is placed below the ground level, and it is in a square shape. When pouring liquid steel slag, first lay a layer of dry steel slag with a thickness of 190-230 mm on the bottom to avoid liquid steel slag from contacting the tank. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com