Laser compound manufacturing rod wire cold shear blade

A bar and laser technology, applied in the direction of metal material coating process, coating, etc., can solve the problems of waste cost and promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

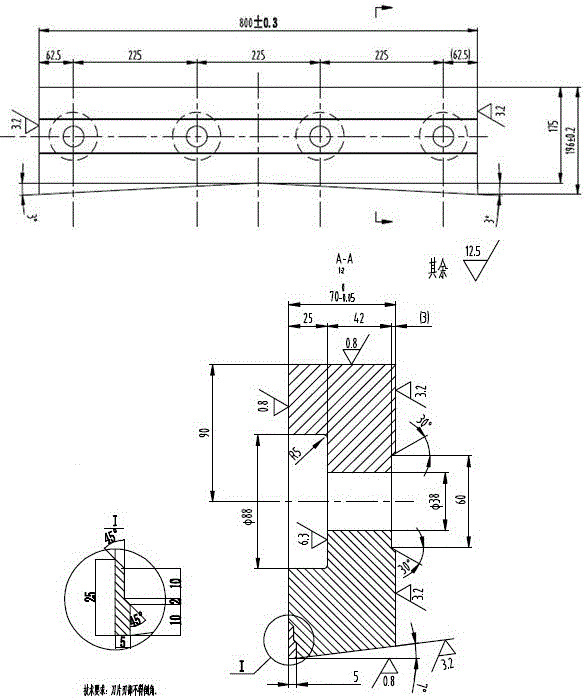

[0017] In order to describe the technical content, structural features, achieved goals and production process of the present invention in detail, it will be described in conjunction with the accompanying drawings.

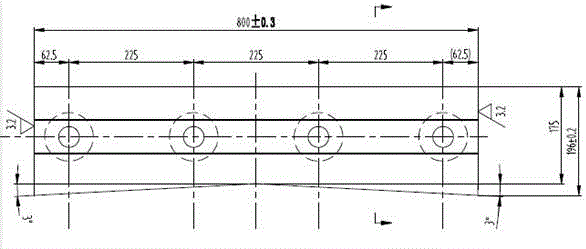

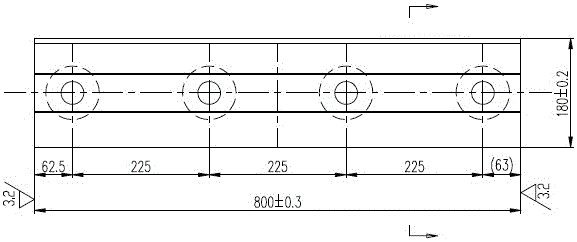

[0018] 1. Press figure 1 upper scissors, figure 2 According to the requirements of the drawing of the lower cutting edge, the thickness of the laser cladding is reserved to make a rough drawing.

[0019] 2. Using carbon alloy steel as the matrix, machining ordinary carbon steel upper and lower cutting edge blanks according to the requirements of the blank drawing.

[0020] 3. According to the drawing requirements of the upper and lower cutting edges, make the rough drawing of the platform 3.

[0021] 4. According to the technical requirements of the rough drawing, gray cast iron is used as the base material to be processed into platform 3.

[0022] 5. According to figure 1 upper scissors, figure 2 According to the requirements of the drawing of the lower cut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com