Fe-based soft magnetic alloy and preparation method of soft magnetic alloy strip

A soft magnetic alloy and alloy technology, applied in magnetic materials, magnetic objects, electrical components, etc., can solve the problems of cutting and winding difficulties, low glass forming ability, high raw material cost, etc., and achieve convenient test operation and excellent soft magnetic properties , good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

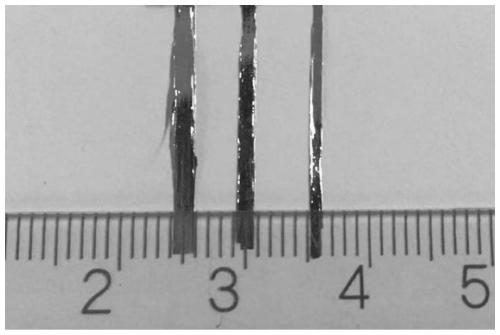

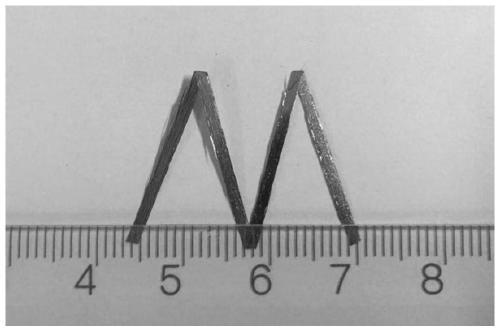

[0038] Preparation of Fe 76 Ni 4 co 4 B 12 Si 4 Amorphous-nanocrystalline soft magnetic alloy strip:

[0039] In the first step, Fe, Ni, Co, Fe-Si alloy and Fe-B alloy of industrial purity are added to the furnace so that the raw materials therein are 76 Ni 4 co 4 B 12 Si 4 The atomic percentages are formulated, and the subscript of each element corresponds to its mole percentage. When batching, first grind to remove the oxide skin on the surface of the metal raw material.

[0040] In the second step, put the proportioned raw materials into the copper crucible of the electric arc furnace, -3 Under the condition of Pa, high-purity argon gas is introduced; under the condition of argon gas protection, the raw materials with good ratio are smelted by electric arc to prepare the master alloy ingot. In order to ensure that the composition of the master alloy is uniform, the master alloy is repeatedly smelted 4 to 6 times.

[0041] The third step is to crush the above-men...

Embodiment 2

[0046] Preparation of Fe 79 Ni 3 co 3 B 10 Si 5 Amorphous-nanocrystalline soft magnetic alloy strip:

[0047] The first step is to add industrial purity Fe, Ni, Co, Fe-Si alloy, Fe-B alloy into the furnace, so that the raw materials in it are 79 Ni 3 co 3 B 10 Si 5 The atomic percentages are formulated, and the subscript of each element corresponds to its mole percentage. When batching, first grind to remove the oxide skin on the surface of the metal raw material.

[0048] In the second step, put the proportioned raw materials into the copper crucible of the electric arc furnace, -3 Under the condition of Pa, high-purity argon gas is introduced; under the condition of argon gas protection, the raw materials with good ratio are smelted by electric arc to prepare the master alloy ingot. In order to ensure that the composition of the master alloy is uniform, the master alloy is repeatedly smelted 4 to 6 times.

[0049] The third step is to crush the above-mentioned ma...

Embodiment 3

[0054] Preparation of Fe 82 Ni 2 co 2 B 8 Si 4 Amorphous-nanocrystalline soft magnetic alloy strip:

[0055] The first step is to add industrial purity Fe, Ni, Co, Fe-Si alloy, Fe-B alloy into the furnace, so that the raw materials in it are 82 Ni 2 co 2 B 8 Si 4 The atomic percentages are formulated, and the subscript of each element corresponds to its mole percentage. When batching, first grind to remove the oxide skin on the surface of the metal raw material.

[0056] In the second step, put the proportioned raw materials into the copper crucible of the electric arc furnace, -3 Under the condition of Pa, high-purity argon gas is introduced; under the condition of argon gas protection, the raw materials with good ratio are smelted by electric arc to prepare the master alloy ingot. In order to ensure that the composition of the master alloy is uniform, the master alloy is repeatedly smelted 4 to 6 times.

[0057] The third step is to crush the above-mentioned mast...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com