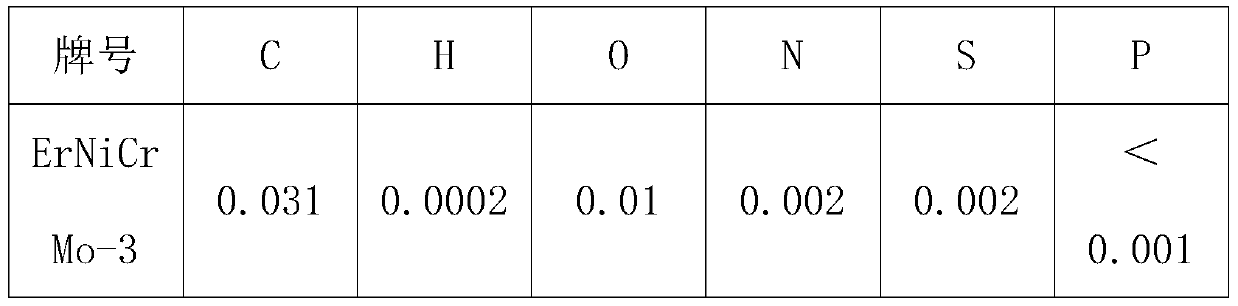

Application of a nickel-molybdenum master alloy in the preparation of ernicrmo-3 alloy

A technology of master alloy and nickel-magnesium alloy, applied in the field of processing technology of nickel-molybdenum master alloy, can solve problems such as segregation, and achieve the effects of fine and uniform particle size, stable product quality, and easy industrial scale production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The process for producing nickel-molybdenum master alloys includes the following steps:

[0015] The content of nickel in the master alloy is 30%-60%, and the rest is molybdenum.

[0016] Step 1, material preparation: take nickel by weight ratio: 30%-60%, and the rest is molybdenum. The proportion of the ingredients is the eutectic point of the alloy, which is easy to realize the crushing of the intermediate alloy in the subsequent processing;

[0017] Step 2. Furnace loading: first put part of the nickel into the bottom of the crucible, then put the carbon into the crucible, then put the rest of the nickel into the crucible, put the molybdenum into the alloy bin, and put a small amount of nickel-magnesium alloy and carbon into the alloy bin. This furnace loading sequence is conducive to the removal of harmful impurity elements and deoxidation to ensure the purity of the alloy;

[0018] Step 3. Melting: Vacuumize until the air pressure in the crucible is less than or ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com