Manufacturing method for blank of length-unequal arc sheet metal part

A manufacturing method and long-arc technology, applied in the field of sheet metal blank manufacturing, can solve the problems of large machining allowance of parts, unfavorable enterprise competitiveness, and low material utilization rate, so as to achieve small machining allowance and improve enterprise competitiveness. , The effect of reducing the difficulty of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

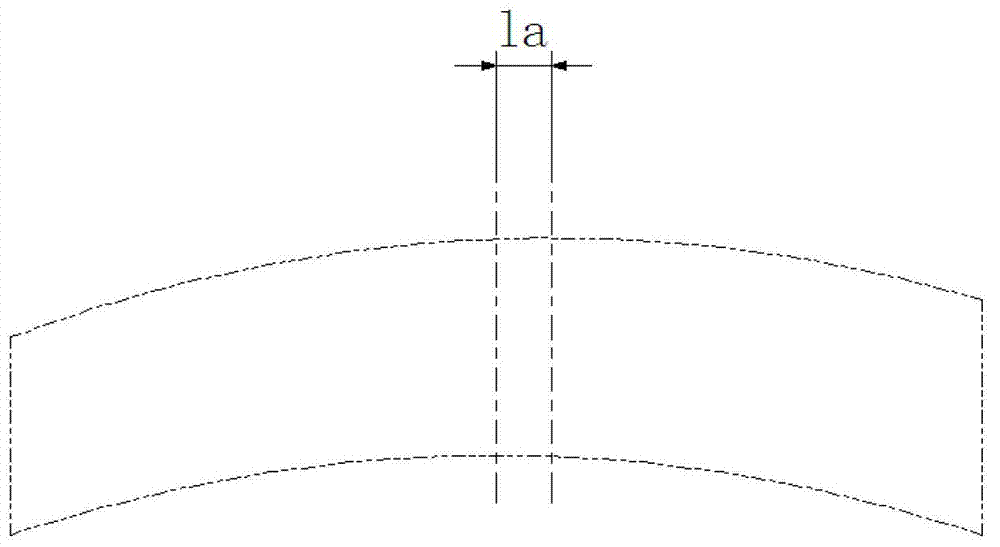

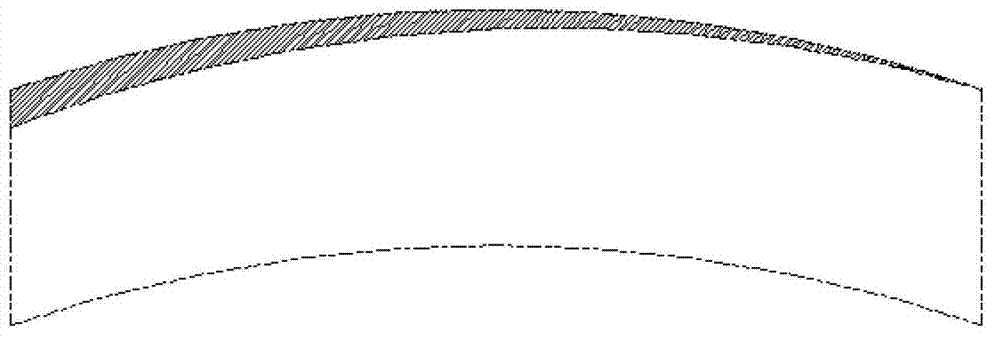

[0017] figure 1 It is a schematic diagram of an equilateral arc-shaped blank in the prior art, figure 2 It is a schematic diagram of the unequal arc blank of the present invention, image 3 For the present invention and prior art material utilization comparison chart, Figure 4 It is a schematic diagram of blanking in step a, Figure 5 It is a schematic diagram of blanking in step b, as shown in the figure: the manufacturing method of the unequal-length arc-shaped sheet metal blank of the present invention, the unequal-length arc-shaped sheet metal is processed by an analysis software to obtain an approximate It is an unequal-edge arc-shaped material with equal arc edge R but eccentricity. It uses coil material as the raw material and is manufactured on the blanking die by a mandarin duck-shaped two-step dislocation blanking method, which specifically includes the following steps:

[0018] a. Adjust the positioning block of the blanking die so that the center line of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com